Turning Machines

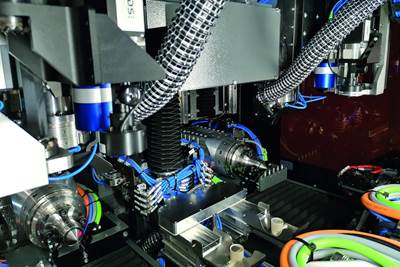

Lathes used for turning parts were the world’s first machine tools. These machines move a static cutting tool down the length of a rotating workpiece to cut the workpiece to shape. Modern CNC turning centers use servo drives to control tool motion compared to hand wheels on manual lathes. Tools install on gang plates or turrets, depending on the type of lathe. Today’s turning centers often can perform milling and cross-drilling operations thanks to live tool spindles that are installed in turret stations that sometimes provide Y-axis movement across the workpiece center line. Turning centers are available in horizontal and vertical main spindle orientations.

Latest Products

Mazak Turning Center Provides High Torque in Compact Footprint

Mazak North America’s QTE-100 MY CNC turning center has a built-in motor spindle designed to provide high torque even in the low-speed range for improved cutting capacity.

Read MoreFryer Lathes Provide High Rigidity for Large-Part Machining

Fryer Machine Systems’ ET-LC lathes are built for small-batch turning of large parts.

Read MoreMazak Achieves Production Milestone, Announces Plans to Open New Technical Center

Mazak Corp. celebrates the completion of its 40,000th machine at the Mazak iSmart Factory in Florence, Kentucky, showcasing advanced manufacturing and digital integration.

Read MoreChevalier CNC Slant-Bed Lathe Automates Small-Part Production

The FCL-130RP’s 30-degree slant bed provides rigid performance, optimal chip removal and long-term machining stability.

Read MoreEurotech Elite Seeks Partners to Build American-Made CNC Lathes

Eurotech Elite hopes to connect and build relationships with U.S.-based, family-owned manufacturers with expertise in machining large components with tight tolerances.

Read MoreMazak Turning Machines Feature Three Turrets for High-Volume Production

The HQR-200/3 and HQR-250/3 NEO machines both have two spindles and three turrets — two upper and one lower — for “done-in-one” part processing and high-volume throughput in single setups.

Read MoreFeatured Posts

Video: Using AR for Remote Machine Tool Troubleshooting

Augmented reality can enable service engineers to help machine shops identify and possibly remedy issues with their machines remotely, perhaps eliminating the time and cost of an on-site diagnostic and maintenance visit.

WatchFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read MorePrecision Machining Technology Review: September 2025

Production Machining’s September 2025 technology showcase includes some of the latest technology from Siemens, United Machining Systems, Mazak, Nikon, IMCO Carbide Tool Inc. and Okuma America Corp.

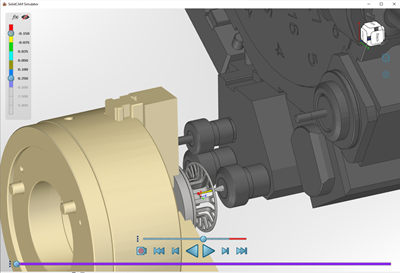

Read More5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

Read MoreGetting the Most Out of Your First Multispindle

A combination of market trends and technological advances have made CNC multispindles an inviting proposition for many shops considering a new equipment purchase.

Read MoreCNC Single-Spindle Automatics: A Possible Alternative to Swiss-Types

For many types of high-production, high-precision machining applications, new CNC single-spindle technology might be a more productive, cost-effective choice.

Read More