LK Metrology Software Updated for Improved Data Collection

LK Metrology’s Camio 2021 CMM measurement, programming, analysis and reporting software has been updated to increase inspection productivity, improve the quality of data collected and gain better insight into the components being measured.

LK Metrology’s Camio 2021 reduces the time for preparing new inspection programs by automatically detecting which surfaces of the CAD model should be used to measure the feature.

LK Metrology’s Camio 2021 CMM measurement, programming, analysis and reporting software has been updated to increase inspection productivity, improve the quality of data collected and gain better insight into the components being measured.

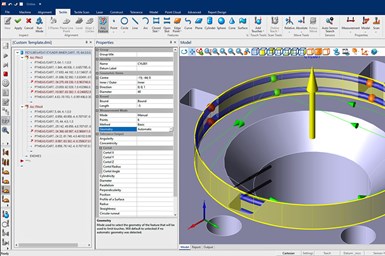

The company says Camio 2021’s geometry validation reduces the time for preparing new inspection programs by automatically detecting which surfaces of the CAD model should be used to measure the feature. It’s been designed to ensure that all measurements are taken on suitable surfaces automatically and at the same time provides the programmer with the option to modify the default settings and selections.

While the feature is being programmed, the CAD simulation highlights the geometry used for the validation and previews the measurement sequence. This combines with the Teach Path view to provide a full visual and numerical evaluation of the programming sequence prior to executing the touch points or scanning sequence, enabling the programmer to get the inspection sequence right first time when programming online or offline. Other improvements have been made to the programming workflow by extending the advanced picking function to touch points and scan paths on a CAD model and to indicate the selection of existing measured features.

New for Camio 2021, probe self-centering enables the center point of a V-groove to be automatically located and measured using a scanning probe. This replicates hard gauging and measurement using gauge balls, typically used for gear tooth inspection and measuring countersink depth. Probe self-centering responds to the continuous deflections of an analogue probe in real time to locate the midpoint between two surfaces.

Camio 2021 orientation tolerancing automatically determines the appropriate relationship to a secondary datum based on the nominal feature definitions. Any manually specified relationship is ignored, except in cases where a relationship cannot be determined automatically. Tolerance zone shape and relationship to the secondary datum outputs have also been added for enhancing the output of orientation tolerances.

Related Content

-

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

-

Why Not Lights-Out Inspection?

Consider a process to enable your CMM to inspect multiple parts unattended, thereby minimizing the impact that part measurement has on your company’s bottom line.