Made4CNC Offers Automatic CNC Door Opening Solution for Robots

The fully electric Safedoor SD100 has built-in safety functions that enable integrators to adjust the speed of the CNC door, making risk assessments easier to conduct.

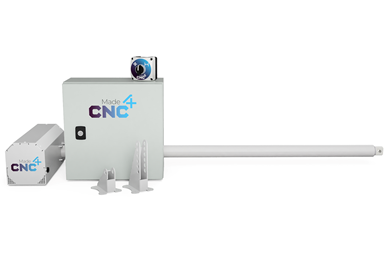

The fully electric Safedoor SD100 offers built-in safety functions.

Made4CNC’s Safedoor SD100 is said to be the world’s first completely automatic door opening solution for robotic machine tending, and can be fitted to any CNC machine in under an hour.

The company says the Safedoor SD100 removes barriers to the automation of component feeding at machine shops with its ability to open CNC doors that are up to 1 meter wide and weigh 400 kg, at a speed of 500 mm/sec. The door opener can connect to any robot and CNC machine via galvanic insulated digital inputs and outputs.

While homemade door opening solutions can risk errors, stoppages and hazardous situations, the fully electric Safedoor SD100 is said to overcome these challenges due to its built-in safety functions. Integrators are able to adjust the speed of the CNC door, making risk assessments easier to conduct.

The SD100 also offers integrated safety and robustness in a user-friendly solution, which the company says is key to optimal productivity. Integration of collaborative robots or light industrial robots — together with existing CNC machines — makes financial sense because the automation of existing machines generates low risk and a short payback period for the customer.

This stable, safe door opener provides customers with a standardized solution designed as a solution-in-a-box, the company says. It is designed to be a complete solution, making it simpler for integrators to work with automation, giving them minimum project risk. The solution also provides a better flow and work environment, the company says. It is designed to make machine feeding more pleasant and easygoing, while providing a more optimized and better work flow.

The SD100 was designed with attention to details in terms of mechanics, software and safety. It is certified by Universal Robots (UR), which means it offers a completely seamless integration with Universal robots. All operation can be done through the robot’s teach pendant.

Related Content

-

Automation Idea for Halloween?

Maybe not. But, the candy-throwing robots at MetalQuest’s Nebraska facility do enable the contract machine shop to stand out at career fairs and similar events.

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.