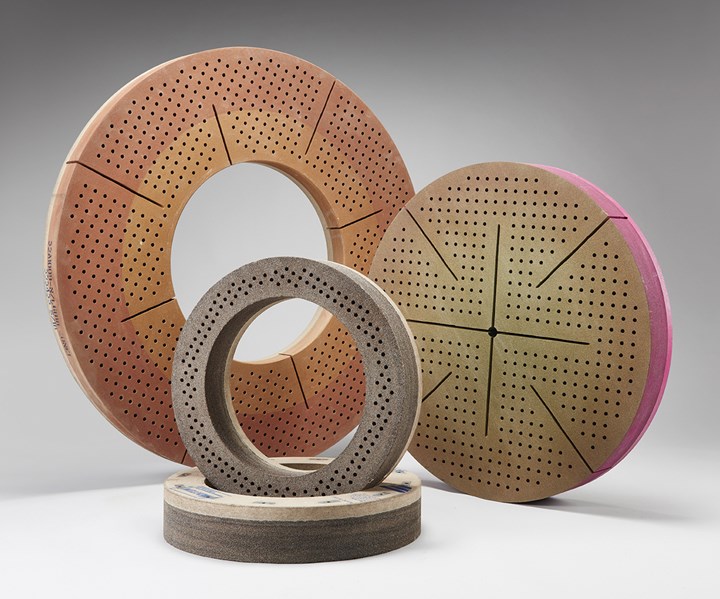

Norton Grinding Wheels Offer Long Life and Consistency

Norton Stellar grinding wheels for double and single disc grinding are suitable for automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Saint-Gobain Abrasives’ Norton Stellar inserted-nut grinding wheels for double and single disc grinding offer improved wheel life, increased parts per wheel and lower cost per part, according to the company. The wheels are suitable for a range of industries including automotive, bearing, tool manufacturing, compressors, knife blades and job shop/ general machining.

Wheels are available in Norton's range of grains and bonds, are made-to-order to fit exact customer requirements and are available in diameters from 8" through 42" and in grit ranges from 16 through 220.

Related Content

-

CAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.