Tungaloy Barrel-Style Cutting Tool Inserts for Finishing, Semifinishing

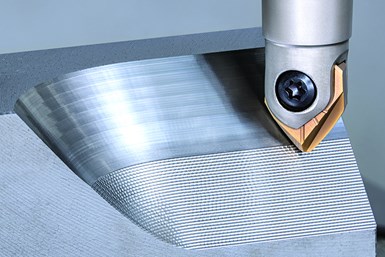

The BallFinishNose indexable barrel-style tool inserts feature an asymmetric shape, which enables users to use the same side of the insert always facing the same direction when set in the tool body.

Tungaloy has expanded its BallFinishNose indexable tool capabilities for profiling complex 3D contours by adding five “barrel-style” inserts for improved cycle time reduction in contoured workpieces.

According to Tungaloy, BallFinishNose is an effective tool in finishing and semifinishing, particularly on geometric surfaces and complex 3D contours common to die mold or aerospace applications. The insert features an asymmetric shape which enables users to use the same side of the insert always facing the same direction when set in the tool body, providing the tool with high repeatable accuracy and reliability, surface quality and predictable tool life.

The five barrel-style inserts are designed to increase efficiency for 3D profile milling capability. The barrel inserts — named for the resemblance of the cutting edge shape to a barrel’s profile — consist of cutting edges with larger radii compared with ball nose end mills, creating greater contact between the cutting edge and workpiece. This enables larger step-over increments to maximize efficiency without compromising on cusp heights and enabling the removal of more material with fewer passes.

The barrel-style inserts can be used with existing BallFinishNose cutter bodies. The inserts are designed to fit the cutter bodies in diameters ranging from 12 to 30 mm (from .472" to 1.181"). The barrel-style inserts’ cutting edge radii are available in 30, 40, 50, 62.5 and 75 mm, and each set of inserts fit the cutter in diameters 12, 16, 20, 25 and 30 mm, respectively.

The inserts feature coolant channels on the insert faces just as those on existing BallFinishNose inserts to ensure optimal coolant delivery close to the cutting area, providing stable and long tool life.

The barrel-style inserts are offered in CH315 insert grade. A combination of extreme wear resistance is made possible by the latest physical vapor deposition (PVD) coating technology and fracture-resistant dedicated carbide substrate for further enabling long tool life.

With the addition of the barrel-style inserts, the BallFinishNose indexable tools are well suited for finish machining of 3D complex surfaces and other intricate profiles typical in die mold and aerospace segments.

Related Content

-

The Value of Swiss-Types Milling Rectangular Medical Parts

High-speed spindle technology was key to effective milling of small cardiac monitoring components complete on a CNC sliding-headstock machine platform instead of running them across two mills.

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Increased Competition Calls for Smarter Solutions

Engineered for efficiency, SW Machines offers customers a full suite of horizontal machining centers and the automation needed for high-volume, high-precision manufacturing.