Update: FDA Releases Draft Guidance for Additive Manufacturing of Medical Devices

The benefits of AM may result in cleaning challenges. The layer-by-layer process of AM allows complex internal support structures and tortuous internal channels.

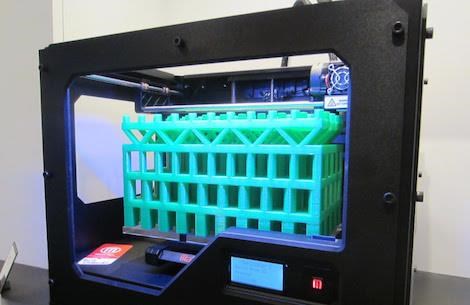

3D printer at work

Readers of Products Finishing will benefit from reviewing and commenting on the new FDA draft guidance document about additive manufacturing for medical devices. Not concerned about medical devices? Not even thinking about AM? Read the document anyway, because the wave of (AM) impacts not only medical devices but also automotive, aerospace products and consumer products.

The document, “FDA’s initial thinking on technical considerations specific to devices using additive manufacturing, the broad category of manufacturing encompassing 3-dimensional (3D) printing,” (1) includes items from a 2015 FDA workshop on AM for medical devices. The document contains a range of aspects of design, printing, and processing. Our area of specialization is critical cleaning and surface quality; and as invited participants to the workshop at FDA headquarters we addressed challenges with cleaning AM devices. As indicated in Section VI(E), of the draft guidance, cleaning processes can be more difficult in AM devices than with those produced by traditional (non-additive) means.

The benefits of AM may result in cleaning challenges. The layer-by-layer process of AM allows complex internal support structures and tortuous internal channels; the result can be a product with desirable features. In addition, products are becoming more complex, including instances where, in post-printing operations, AM is combined with traditional manufacturing processes. This means that particles (including residue of powder from the printing process) and/or metalworking fluids can become entrapped. Manufacturers have to design and demonstrate effective cleaning processes.

To assure that the FDA considers comments before it begins work on the final version of the guidance, they request that comments be submitted by August 8, 2016. (2)

1. “Technical Considerations for Additive Manufactured Devices, Draft Guidance for Industry and Food and Drug Administration Staff”

http://www.fda.gov/downloads/MedicalDevices/DeviceRegulationandGuidance/GuidanceDocuments/UCM499809.pdf

2. Federal Register announcement: https://www.federalregister.gov/articles/2016/05/10/2016-10924/technical-considerations-for-additive-manufactured-devices-draft-guidance-for-industry-and-food-and

Related Content

-

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

-

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

-

Photochemical Etching Explained

This subtractive metal fabrication process is an alternative to traditional methods which enables designers to create thin metal parts with intricate shapes to micron-level precision without leaving behind burrs.