Making large capital investments in equipment that challenges traditional processes can be intimidating for a machine shop. However, after realizing that a particular job can run more efficiently and result in a more quality part, it becomes easier to move forward with the purchase.

When Swiss Precision Machining LLC (SPM) bought its first Willemin-Macodel 408MT five-axis machining center in 2012, President Cassandra Haupers (a PM 2020 Emerging Leader) knew she would not regret it. The Wheeling, Illinois, shop needed a more optimized process for running a part used for

Featured Content

Since the integration of SPM’s five-axis machines, the shop has experienced an excessive amount of work, so much that it cannot fill orders quick enough. Therefore, three more five-axis machining centers will be delivered this year that President Cassandra Haupers hopes will be enough to keep up with business. Photo Credit: Swiss Precision Machining Inc.

meniscus surgery that was being manufactured on one of its CNC Swiss-type lathes. She never forgot seeing the machining center at the 2004 International Manufacturing Technology Show and convincing herself that it would be a better solution for that particular job. But she had to coerce her father (who was president at the time) to invest in the machine. After he finally agreed, over time the bar-fed machine tool’s performance — including the ability to run lights-out — proved to them that they made the right decision.

Eleven years later, that same part, along with other complex parts, is machined complete on the five-axis machining center with better finishes than when created on the Swiss-type. The machining center, which the shop now has seven, also enables the machining of a broader range of medical parts while expanding SPM’s customer base.

“It’s not so much about improved cycle times on the Willemins, but we are able to do jobs that we weren’t able to do before,” Haupers explains. “What’s important are the opportunities that we’ve been able to see because of these machines.”

The Name Does Not Say It All

Originally predominantly a CNC Swiss-type machine shop, Haupers is concerned that SPM’s name no longer tells the whole story about the company’s capabilities.

“I think sometimes our name gets us in trouble because it pigeonholes us,” Haupers says. “We do a lot more than Swiss-type machining now. I think five-axis milling, for example, is something we are really good at.”

Prior to diving into five-axis machining, the shop, which opened in 1979, mostly machined dental parts on its CNC Swiss-type lathes. Although it currently runs 72 CNC Swiss lathes (by far the largest amount of one machine tool type on its shop floor), the market the shop serves has changed dramatically over a 10-year period. Prior to implementing the five-axis machines, the shop’s customer base was 65% medical and 35% other industries. But since integrating the new machines, it has transitioned to 85% medical device/medical technology market, with a heavy focus on robotic-assisted surgery, and 15% other industries.

Its 82,000-square-foot facility also houses 10 Haas Automation vertical machining centers (VMCs) as well as its seven five-axis machines (six Willemin 408MT models and one 508MT2). The company also assembles machined parts with its automated assembly process. And it offers engineering services, including design for manufacturability.

Mission Accomplished

With a company mission to “craft immaculate, high-quality components through industry-leading technology and genuine experience …,” it is understandable that when one part order’s manufacturing quality was compromised, Haupers prioritized purchasing the first Willemin 408MT. She explains she was in jeopardy of losing a customer because the CNC Swiss could not produce the part at the expected quality requirements necessary to be used for meniscus surgery.

SPM’s six Willemin 408MT five-axis machining centers are all located in the same room on the shop floor so it is easier for one machinist to attend all of them. Photo Credit: Production Machining

“The support isn’t there on the Swiss machines as it is for the Willemins,” Haupers says. “In the five-axis machines, we can machine in a vise block, but we cannot on the Swiss.”

However, the five-axis machines now not only deliver the necessary quality surface finishes but are dedicated to small, complex geometries that are necessary for that particular part as well as the other part orders the company has gained by implementing these machining centers. Most important, the machines can hold tolerances as tight as ±0.0001 inch, which is necessary to create some of its customers’ parts.

SPM’s five-axis machining centers, which can perform turning, milling, drilling and boring, are all bar-fed with mostly stainless steel and titanium. The smallest parts the company produces are 0.250 inches in length and 1.5 inches in diameter. Batch sizes vary from tens of thousands of parts a year to 100 to 200 parts a year. However, some of the machining centers are churning out prototypes that can include batch sizes of 5, 10 or 100, 250 parts per year. The completed parts are ejected from the machine by a conveyor belt as well as some carousel collection systems.

According to Haupers, the machining centers’ normal cycle times are anywhere from a few minutes to up to 30 minutes. She recognizes that cycle times are not faster than CNC Swiss cycle times. However, she has learned that producing short cycle times is not always the most critical aspect of machining, especially when running complex parts like the ones the five-axis machines are producing that require more processes than turning.

SPM manufactures medical device parts on its Willemin machining centers in sizes from 0.250” in length, and 1.5” in diameter. Batch sizes vary from tens of thousands of parts a year to 100 to 200 parts a year. Some of the machining centers are churning out prototypes that can include batch sizes of five or 10 to as many as 100 or 250 parts per year. Prototypes enable SPM to collaborate with customers including opportunities for design for manufacturability. Photo Credit: Production Machining

But what is faster are changeover times on the machining centers due in large part to the machines’ tool magazines. SPM’s five-axis machines’ toolchangers hold up to 72 tools and have a 0.8-second tool change time. “The operator calls up the program on the Willemin and uses those tools that are in the carousel, rather than on the Swiss, where you have to set a tool for each setup,” Haupers clarifies.

Both the 408MT and 508MT2 are equipped with a swiveling powered spindle fitted on a B-axis and an A-axis spindle, enabling up to 6,000 rpm in turning mode. However, the 508MT2 is capable of simultaneous machining with the pickup device/vice that grabs the parted-off part for backworking. This provides two more axes other than the main five axes. Therefore, it is sometimes called a seven-axis machining center.

The only Willemin 508MT2 on the shop floor is capable of simultaneous machining with the pickup device/vice that grabs the parted-off part for backworking. Photo Credit: Production Machining

The machining centers use GibbsCAM CAD/CAM software. Although there was a learning curve to figure out how to program this new machine platform for SPM engineers, they quickly picked up the program after some training by Willemin and GibbsCAM.

Quality Machines Need Quality Tooling

Haupers is happy with SPM’s tooling and accessories for the five-axis machining centers. The machines use carbide cutting tools from Mitsubishi and drills, end mills and custom tools from Harvey Tool. They also use a Rego-Fix PowRgrip toolholding system and a tool detection system that sounds an alarm when a broken tool is detected. ProLink Statistical Process Control (SPC) quality data collection is available at the machines as well. This data is used to help analyze trends in tool wear and determine when offsets or tool changes are needed.

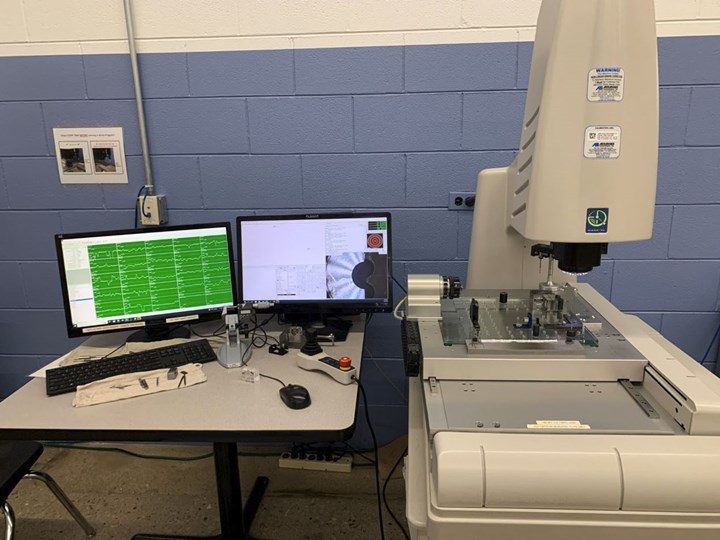

For increased quality control, the shop is equipped with seven Micro-Vu Vertex automated precision measurement systems, which are used to measure parts coming off the five-axis machines. In fact, the noncontact, camera-based measuring devices are located in the same room as these machining centers for operator convenience. The company is also equipped with one Evo Cam digital microscope from Vision Engineering.

For its parts that necessitate cleaning, the facility houses an iFP vacuum parts washer distributed by Gosiger.

For increased quality control, the shop is equipped with seven Micro-Vu Vertex automated precision measurement systems. These noncontact, camera-based measuring devices are located in the same room as the five-axis machining centers for operator convenience.

Photo Credit: Production Machining

And to create fixturing for inspection purposes, the shop owns a small polymer 3D printer by Ultimaker.

Optimizing Shopfloor Talent

With 140 employees and aiming to hire about 10 more, SPM has not evaded the hardship of finding skilled machinists. However, the five-axis machines have eased the pain of the facility’s skills gap. For example, the machines have eliminated secondary processes that used to take an operator’s time to move unfinished parts to the next process or machine on the shop floor.

This diagram illustrates the movement of the five-axes inside the machine. A, B and C axis movement is accomplished by 360-degree bar rotation and -45 to +115 degrees of spindle rotation in the B axis, respectively. Photo Credit: Willemin-Macodel

“We had a lot of extensive secondary operations that were needed on certain parts after machining on a Swiss lathe,” Haupers states. “We’ve been able to move some parts over to these five-axis machines and eliminate these secondary ops.”

Machinists are also freed up to lightly attend these machines because of their efficiency — one machinist runs four machines.

The machining centers also have created a lights-out shift overnight at the shop, facilitating even more productivity. Besides the tool detection system in place on the new machines, tool counters and sister tools are used to enable lights-out machining. Haupers explains they also use the SPC data to know when the optimal time is to run lights-out.

Booming Business

Since the integration of SPM’s five-axis machines, the shop has experienced an excessive amount of work, so much that it cannot fill orders quick enough. Therefore, three more 408MT machining centers will be delivered this year that Haupers hopes will be enough to keep up with business.

Haupers expresses her excitement about breaking into other industries that the shop could not tap into until the past several years with the new machines. Jobs like grippers, graspers and endofactors for the robotic-assisted surgery market could not have been machined on the shop’s CNC Swiss lathes, she says. SPM is an example of how adopting new machining technology, while it can be challenging, can ultimately lead to overall growth.

Swiss Precision Machining LLC | spmswiss.com

Willemin-Macodel Inc. | willemin-macodel.com/en

GibbsCAM | gibbscam.com/en

Gosiger High Volume | gosiger.com

Haas Automation | haascnc.com/index.html

ProLink | prolinksoftware.com

Rego-Fix USA | regousa.com

Ultimaker | ultimaker.com

RELATED CONTENT

-

Automatically Deburr, Clean Parts in One System

Palletized parts are transferred from a five-axis, high-pressure waterjet station to a cleaning station via linear motor to enable fast, automated finishing.

-

Can You Pull Data From a Solid Model to Perform Five-Axis Conversational Programming?

A CNC feature imports a 3D solid model from which operators can perform conversational-type, five-axis programming.

-

Five-Axis Fixturing Fun

This shop creates intricate fixtures — some of which it has given interesting names — for very complex jobs and high-volume work on five-axis machining equipment.