EMO 2019 Observations from the Barber’s Chair

Business trips can be disruptive to the routine, but an opportunity to see a show like EMO 2019 should not be missed. Smart technologies are driving tomorrow’s production.

A halfway decent haircut will go a long way!

— G-Eazy

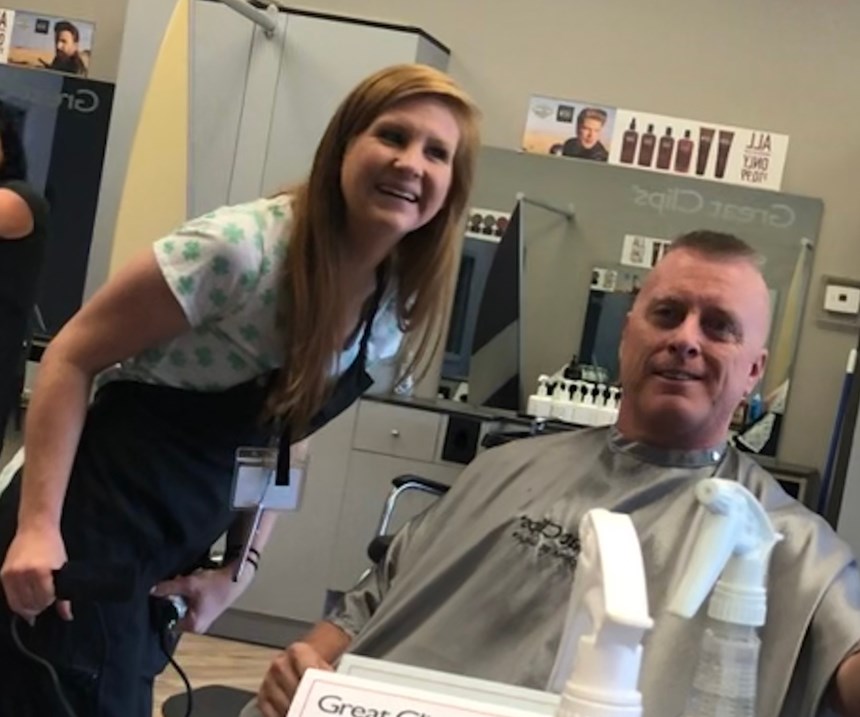

Every trip for me starts the same way. It’s probably related to my tendency to seek consistency, but I also have a practical reason. Shortly before I leave, I head to my favorite stylist for a haircut. I want to look my best while I’m away, but I also know the short hairstyle will require little maintenance throughout the week—one less thing to worry about. Hours before my flight on a Saturday in mid-September, I drove to see Lauren.

Lauren does more than cut my hair. I don’t think she really knows anything about manufacturing beyond what I’ve told her, but she’s good at her job—she listens to my stories. Now she knows I was headed to Hannover, Germany, for EMO 2019—the world’s biggest metalworking trade fair—and she gets to discover more about the show through me, as I fill her in about my first experience there.

I boarded the plane at 5:30 p.m. for an eight-hour flight to Paris, a five-hour layover, then an hour and a half to Hannover. With the time difference, I reached my destination at about 1:00 Sunday afternoon. I struggle to sleep on planes, so I was tired. But it seemed I could feel the energy from the show from the moment I stepped out of the airport. Adrenalin carried me through the quick trip to the hotel, then an evening out with colleagues before a good night’s rest to hit the ground running first thing Monday morning.

Did I say a good night’s rest? Well, my first night in a “strange place” doesn’t usually go well, either. I got two hours of sleep. But that’s okay. I’ve been to other trade shows before. I knew what to expect and what I’m capable of. I was good to go!

The train station was a short walk from the hotel, and the train dropped us off at the north entrance to the fairgrounds. Suddenly the words I had heard about EMO, “It’s a really big show,” began to sink in. First on my schedule was an opening press conference with VDW (German Machine Tool Builders’ Association). Many of the press conferences, including this one, took place in the Press Center, which was near Hall 16. That’s right, I said 16. Exhibitors occupied a total of 18 of the almost 40 buildings on the site. An efficient walking plan goes a long way in making a week at this show productive.

That first day went fast. I attended several other press events, including ones hosted by CECIMO (European Association of the Machine Tool Industries and related Manufacturing Technologies) and TAITRA (Taiwan External Trade Development Council). I learned about UMATI, a universal machine tool interface developed by VDW and 17 other partners that include major machine tool builders, application partners and control technology experts. I also had a little time to get into a couple of the exhibit halls, each of which were similar in size to those at other shows I’ve attended.

Tuesday was my busiest day, with a full schedule of press events, including an elaborate introduction to DMG MORI’s latest developments focusing on stability, cost savings and innovations for the future. The company’s 10,000-square-meter booth took up the entire Hall 2. At another press conference, JMTBA (Japan Machine Tool Builders’ Association) discussed the state of the Japanese economy and provided details about JIMTOF 2020, which will be held in Tokyo, Dec. 7-12, next year.

On Wednesday and Thursday, I had a few scheduled appointments, but also finally had a chance to find my way through each hall to try to make some discoveries of my own. Fastems is providing manufacturing management software and automation solutions to allow longer unattended machining, including turning operations. The folks at Mastercam discussed the continuing expansion in the use of mill/turn and how the company’s software has evolved to facilitate these operations. Ecoclean has developed a modular system that combines both parts cleaning and deburring operations.

With a show this big, no one person can see it all. I did my best to tackle as much as possible, and while a bit overwhelming, it was worth the trip. I’ll be due for another haircut soon. I’m sure Lauren is anxiously awaiting the details of my experience.

Read Next

When You Know it’s Right

Unfortunately, not all major decisions are this easy. This life-changing choice, though, is a no-brainer.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More