Editorial, News, and Products

Expanding Offerings with Max-Bar Tooling

Somma Tool Co. has a history of taking advantage of opportunities to help the business thrive. Recently, Somma Tool found a way to expand its product line, and market, by acquiring the Max-Bar Tool Co.

Somma Tool Co. Acquires Max-Bar Tool Co.

Cutting tool company expands product range through acquisition.

Somma Tool Co. Celebrates 80th Anniversary

In 1939, Gerard J. Somma, a recent arrival from Naples, Italy, saw a growing demand for a local, reliable source of screw machine tooling and decided to take the plunge. He incorporated Somma Tool Co. in his new home state of Connecticut and never looked back.

Somma Inserts Supply Any Option

Somma Tool is said to supply all the options needed by companies who use form tools.

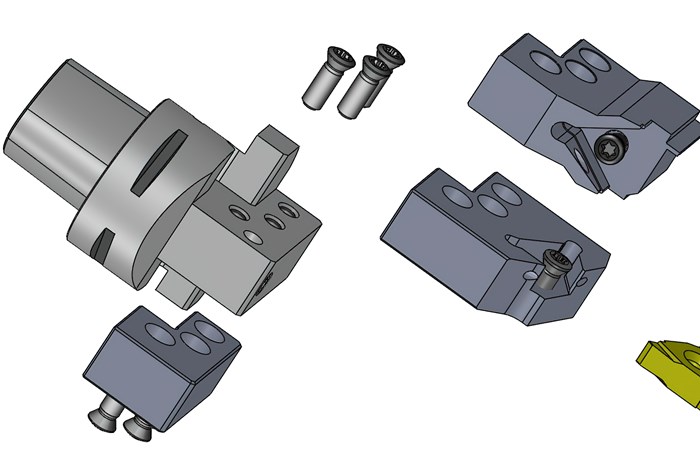

Max Bar Mini Shank Toolholders Fit Swiss Machines

Somma’s Max Bar series of mini shank toolholders are designed to fit Swiss machines and can be used for front turning, back turning, cutting off, grooving, and threading, as well as plunge and turn, face grooving, ID grooving, threading and boring.

Somma Tool Announces the Acquisition of Reynolda Cutting Tools

Somma Tool Company has purchased the RCT line from Reynolda Manufacturing Solutions.

Somma Tool Values Collaboration Among PMPA Members

There is such a high level of collaboration even though the members may be competitors; everyone is willing to give to others.

Another Look at Skiving

Although recognized as one of the oldest and most efficient methods for producing long and slender parts and others on screw machines, skiving is still often avoided because many layout and setup personnel and operators lack sufficient knowledge to successfully apply the process.

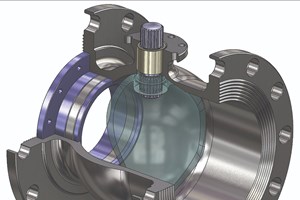

The Basics of Rotary Broaching

This broaching process creates a non-round shape on the inside or outside of a part with a broach tool.

Collet Chuck-Style Broach Toolholders

The new collet chuck-style broach toolholders are said to be versatile because they use ER-style collets, which are designed to reduce the three-screw method of centering the HSS broach in the broach toolholder. The ER-style collet will hold virtually any diameter shank broach tool in the holder within the range of the collet. A built-in stop screw allows the operator to adjust for different length broaches and to compensate for different lengths on re-sharpened broaches.

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

Technical Member Profile: Somma Tool

Somma Tool Company, Inc. offers a full line of tooling for screw machines, lathes and CNC machines. With 30 employees at its 28,000-square-foot facility in Waterbury, Connecticut, the company specializes in manufacturing cutting tools, holders and precision machining accessories.

The Case For Resharpenable, Insert-Type Form Tools

Users explain the advantages of these tools over solid and throwaway-insert-type form tools.