Shops often exert a lot of effort toward selecting the best toolholder for a particular machining application. That’s because toolholders are important for effective and safe connections between high speed tools and a machine, and choosing the right toolholder is the key to greater precision, longer tool life and decreased machining costs.

Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM received from supplier companies. For January, we focused on toolholders, including a modular tooling system with a coolant-through design; an online form tool service to simplify ordering holders and inserts; hydraulic chucks featuring tool-side clamping for faster and safer tool changes; and more.

Take a few minutes to check out some of the latest new and/or improved products in the precision machining industry as described below. For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s December Technology Review.

Click on each link below to read the full product post:

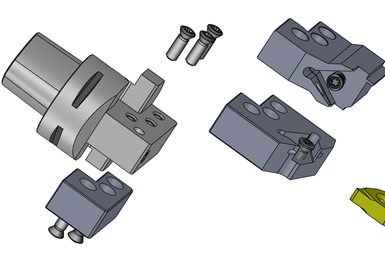

Schwanog's MSIK modular tooling system. Photo Credit: Schwanog

Form cutting tool manufacturer Schwanog has developed the MSIK modular tooling system by which the coolant is supplied internally and directly to the cutting edge through the base body and cartridge. The company explains that modular tooling systems are increasingly being used in the metal cutting industry because they offer significant advantages over conventional clamping systems.

The service is divided into four categories, including RQC for resharpenable quick-change inserts. Photo Credit: Somma Tool Co.

Somma Tool Co. has developed an online Form Tool Freedom service to simplify the ordering process for procuring holders and inserts that best suit customers’ production requirements. The service is designed to provide complete services to companies that use form tools. Online supply category options include RQC for resharpenable quick-change inserts; STA for single-use, throwaway inserts; DIY for make-your-own inserts; and SES for Somma to help customers design inserts.

To minimize machine downtime and provide operator safety, these hydraulic chucks use a simple hex wrench that requires only two to three turns for both clamping and unclamping. Photo Credit: Big Kaiser

Big Kaiser’s hydraulic chuck line expands with Standard Type, F Type and R Type chucks for Swiss-type lathes which feature tool-side clamping for faster and safer tool changes that eliminate machine downtime and make for easier cutting. Standard Type hydraulic chucks are available in inch sizes with the clamping range diameter of 1/8", 3/16" and 1/4”.

Allied Machine and Engineering’s Wohlhaupter 538 (537) boring cassette. Photo Credit: Allied Machine and Engineering

Allied Machine and Engineering’s Wohlhaupter 538 (537) boring cassette features an external 3ETech digital display for micro-precision adjustment. The 3ETech combines precision adjustment measurement in the tool with an external, dockable and detachable digital display that shows the adjustment setting. This user-friendly, micro-precision readout capability facilitates reliable machining processes for high-precision components, the company says.

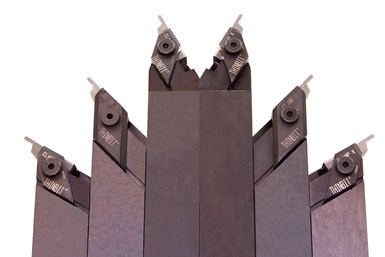

Kaiser Tool Co.'s Thinbit square angled toolholders. Photo Credit: Kaiser Tool Co.

Kaiser Tool Co. is expanding its offering of Thinbit square angled toolholders which are designed for CNC and conventional machines. The angled square toolholders position the insert at 30-, 45- or 60-degree angles for reliefs, undercuts, angled OD and face grooves. Square shank sizes are available in diameters of 3/8", 1/2", 5/8", 3/4" and 1".

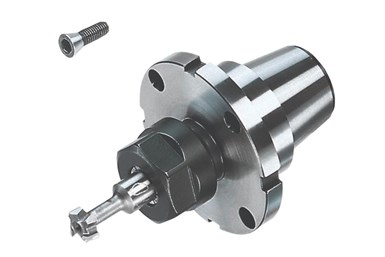

Exsys Automation Type 01 ER Collet Chuck Standard Adapter. Photo Credit: Exsys Automation

Exsys Automation’s Type 01 ER Collet Chuck Standard Adapter enables shops to change over tools in turning center turrets quickly, accurately and economically, the company says. For machining close to the outer diameter or inner diameter of a workpiece, the Type 01 Adapter extends drills or endmills away from the face of the toolholder for additional reach.

RELATED CONTENT

-

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.