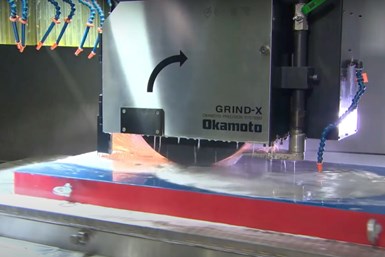

Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For November, we focused on grinding technology, which is commonly one of the last machining operations performed to complete a part. Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations.

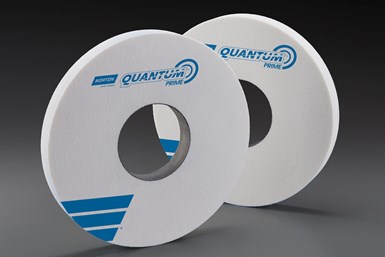

PM’s November Grinding showcase includes a cylindrical ID-radius grinding machine well suited for tough ID grinding operations; a hybrid, 6‐axis tool and peel grinding machine; grinding wheels featuring a nanocrystalline ceramic grain; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s October’s Technology Review.

Click on each link below to read the full product post:

Related Content

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreShould You Bring Tool Regrinding In-House?

In some situations, the potentially high investment in an in-house tool grinding process can be justified with a relatively fast ROI. (Includes video.)

Read MoreCAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Read MoreShop Optimizes its Swiss-Turning Flexibility

Paramount Machine uses various Swiss-type lathes, some with a B axis, to produce parts more effectively than it did on conventional chucker lathes. Today, nearly every job under 1.5 inches in diameter runs across those machines even if the batch size is a mere 5 pieces.

Read MoreRead Next

Precision Machining Technology Review September 2022: Cutting Tools

Production Machining showcases some of the latest cutting tools, including technology from Heule Precision Tools, Horn, Ceratizit, Ingersoll Cutting Tools, Schwanog and Walter.

Read MorePrecision Machining Technology Review August 2022: IMTS Automation & Robots Preview

Production Machining’s IMTS Automation & Robots preview showcase includes Edge Technologies, Absolute Machine Tools/Productive Robots, LNS North America, FANUC America, Universal Robots and Lang Technovation.

Read MorePrecision Machining Technology Review October 2022: Toolholders

Production Machining showcases some of the latest toolholders, including technology from Goeltenbodt, Horn, GenSwiss, iSwiss, Iscar and Kaiser Tool.

Read More