Shop Opts for Choice in Swiss Machines

Precision CNC (Lancaster, Ohio) is a traditional machine shop that has moved into Swiss machining. From the beginning of its Swiss operation, it has used “combination” machines in its stable of Swiss-types, which offer machining capability with or without a guide bushing. Here’s how and why it uses them.

Once there were Swiss shops and there were traditional machine shops. The demographic was fairly clear. Swiss shops were considered screw machine shops, and machine shops, well, weren’t.

That line of demarcation began to blur once CNC technology was applied to the Swiss automatic, and the accuracy and versatility of the sliding headstock design became apparent to many shops that previously would not consider using cam-actuated machine tools. Programming servodrives in G code was the world they knew.

Precision CNC is a good example of how that once relatively solid line between traditional machine shops and Swiss shops is blurring. The shop’s history began as a machine shop and has evolved to include a productive Swiss machining operation as part of its overall and extensive machining capability, which includes three- and four-axis milling, eight-axis mill-turn, turning, precision welding and fabricating, rapid prototyping and engineering services such as high level CAD/CAM driven by a staff of mechanical engineers. It’s an evolving shop that chooses appropriate technology to help it move forward.

The Best of Times, the Worst of Times

“Our story begins in 2006,” says Nate Hawkins, owner of Precision CNC. “We spent that year setting up our machine shop. Our strength was we didn’t shy away from difficult jobs or materials. We did a lot of 3D surfacing, tight tolerance work in tough materials such as Hasteloy and Inconel. It was our specialty.”

Through 2007, the company grew steadily, and as 2008 rolled around, it was doing very well. Word of mouth from the customers was spurring growth, and the shop continued to add machining capacity to serve its customers. Multi-axis turn-milling, five-axis machining, turning and several other operations became part of the shop’s portfolio.

“We were poised for a good 2008,” Mr. Hawkins says. “From January to September all was good. Then, as we all remember, Lehman Brothers failed, and we were swept up in the Great Recession. It was so abrupt; the phones stopped ringing and the quotes stopped coming.” However, within a month, the shop was busy again, according to Mr. Hawkins, but the customer mix had changed. “We were getting work from industries such as fluid power, food processing, automation and recreation to name a few. Good work, but different from the tight tolerance, specialty materials machining we were used to.

“During that time after the recession hit, we could get plenty of work, but the margins were unsupportable,” Mr. Hawkins says. “It was decision time for the shop.”

Mr. Hawkins hit the road and visited companies in an effort to secure work and help them with lead time and efficiency issues. What he found was that unless a job could be turned around quickly, the odds of securing the work were slim.

Acting more or less as a consultant to these prospect companies, Mr. Hawkins found that unless his shop had equipment ready to go, and they could get a purchase order off their desk that day it was very difficult to turn that into chips. After about a year of building new relationships and seeing how bad the economy had become, Mr. Hawkins saw many companies trying to bring outsourced work in-house and hang onto their core employees.

“That led us to the decision that we would have to get a machine in order to get the work,” says Mr. Hawkins. “Every owner prefers the idea of buying a machine that is full of work. We decided to approach the problem from the opposite end and create an opportunity to have capacity and capability in place. So we bought our first eight-axis twin spindle, twin-turret machine more or less on speculation.”

Mr. Hawkins sent his key people, all of whom had been retained through the recession, to training for these more complicated machines and invested in Partmaker CAD/CAM for programming the multitasking machines. There were some jobs for the new machine, and gradually the shop was able to get more work—some of it being proprietary, but well applied to the new machine.

The plan worked, and the first machine became a second, then a third. “The multi-axis business grew for us,” Mr. Hawkins says. “We had the people in place, infrastructure and the machines to do the kind of work we are best at.”

Looking Forward

“With business improving and the shop’s expertise with multi-axis machining in place, I started looking at where we should go next to keep growing the business,” Mr. Hawkins says. “Even though we had no experience in it, the Swiss machining concept just made sense for our shop’s next step.”

The company applied its lesson from the venture in multitasking turn-mills by getting a Swiss-type machine to learn from and then find work for it. In 2010, Precision CNC bought its first Swiss, a 32-mm Tsugami. However, with an eye toward flexibility, the shop ordered the machine equipped as a combination machine with interchangeable chucker or guide bushing capability, and we are now considered amoung the best Swiss shops in the region.

“Our Tsugami rep, John Corrigan at Technical Equipment, was very helpful guiding us through the teething pains of taking on a new processing capability, and we are now considered among the best Swiss shops in the region,” Mr. Hawkins says. “In addition, Chad Dixon, our production manager, worked internally to learn about and take the lead implementing that technology in our shop. Every shop needs a guy like that when trying something new.”

What is Combination Swiss-Type?

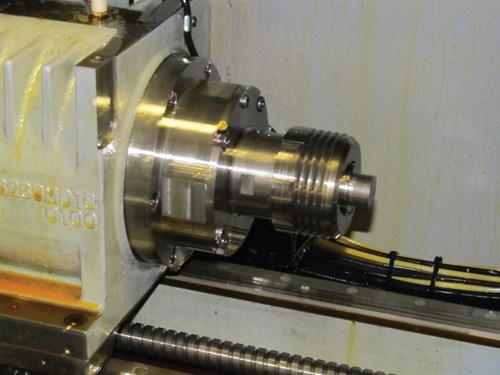

Historically, the defining feature of any Swiss-type machine is its sliding headstock and guide bushing arrangement. However, in recent years, and especially with the application of CNC technology, machine tool builders have begun offering sliding headstock machines that have the option of using a guide bushing or, for parts better accommodated by chucking, by extending the Z-axis headstock stroke into the workzone and supporting the bar or blank using a standard collet, eliminating the need for a guide bushing.

These machines have grown in popularity in part because many of the workpieces that are machined on Swiss-type machines are not really what one might consider as Swiss parts. Some industry estimates put 50 to 60 percent of parts run on guide bushing Swiss-type machines are misapplied and would run better on a chucker sliding headstock arrangement. Primarily those “chucker” applications involve workpiece blanks with a sufficiently rigid length-to-diameter ratio that they don’t require a guide bushing.

According to Mr. Hawkins, there are some fundamental reasons that he and his partner Paul Davis chose to go the combination route with their Swiss machine purchases. Currently, four of the company’s six Tsugami machines have the capability of running with or without a guide bushing. “If the combination option is available on the model we are looking at, we order it equipped that way,” Mr. Hawkins says. His reasons are varied, but primarily reflect the shop’s traditional machine shop history, which puts a premium on flexibility and quick response to customer needs.

Applying Combination Swiss

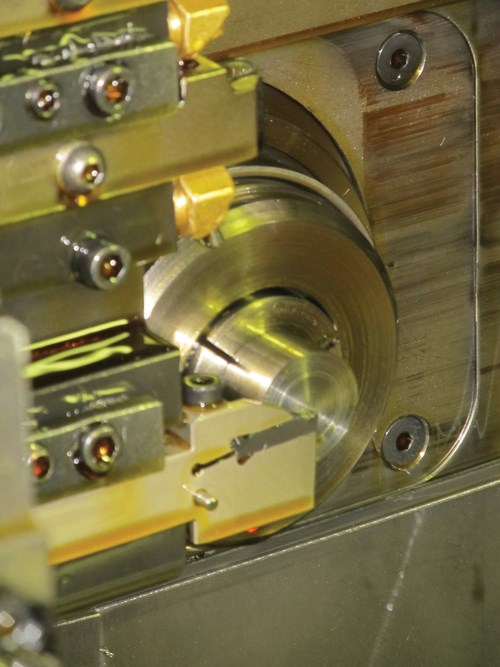

“We started running work across our first Swiss machine in the 4,000 to 5,000 piece lot size. Today we are in a position to produce from prototype to lots in the hundreds of thousands,” Mr. Hawkins says. “One of the first parts we put on the machine were hydraulic spools that had some turning and drilling requirements and were well applied to a Swiss-type machine. At first, we were running jobs that were 0.25 inch by 3 inches—traditional Swiss parts—then switching to a job that was 1 inch by 0.375 inch. We’d remove the guide busing for the second part, and run it as a chucker. The change-over is about 30 minutes.”

The ability to switch from traditional Swiss mode to chucker mode is attractive, because there are some production advantages to running in the chucker mode. The switch from guide bushing to chucker is a little shorter the other way because the need to adjust the guide bushing and align the Z-axis stroke to its center-line is eliminated.

There are some inherent advantages of the chucker mode capability that Mr. Hawkins has found on the Tsugamis. One big advantage, he points out, is the need for ground barstock is eliminated. The collet used in the chucker mode has a larger grip range, so ground stock isn’t necessary.

Moreover, the chucker delivers better concentricity because the collet is gripping the raw material, and there is no need for a tolerance to allow the blank to slide through the guide busing. Also, the remnants from the chucker mode are about half the length of the Swiss mode.

Mr. Hawkins also notes that for milling operations, the rigidity of the colleted blank help produce more accurate features on the work when cutting axially or radially. Within the chucker length-to-diameter range, multiple passes and stepped workpieces run better on the chucker.

“The key to applying these combination machines is not necessarily the ability to switch them back and forth,” Mr. Hawkins says. “As an owner, investing in any piece of equipment, while I have an idea of how it will be applied in the shop; it’s never a sure thing. I prefer to hedge my bet and err on the side of flexibility. So far, it’s a policy that is working for Precision CNC.”

Related Content

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreCAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Read MoreWhen a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MorePlanning for Growth Amid Uncertainty

Six strategies to maximize a company’s success amid unpredictability.

Read MoreRead Next

Switching to Swiss Without a Guide Bushing

When the part doesn't require a guide bushing, being able to remove that housing provides increased flexibility and often even improves accuracy.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More