Switching to Swiss Without a Guide Bushing

When the part doesn't require a guide bushing, being able to remove that housing provides increased flexibility and often even improves accuracy.

A distinct advantage that Swiss-type machines offer is extreme accuracy for parts with length to diameter ratios greater than 3-to-1. The guide bushing helps to provide rigidity of the part. But for shorter parts, a precision collet is typically all that is necessary for part support, and a guide bushing only adds to the complexity of setups and the stock needed to run the job. Often a shop can schedule its parts on one type of machine or the other, depending on availability, part specs, and accuracy requirements. But what if a shop does not have that kind of flexibility because of a limited number of machines or a high volume of jobs that must run on one type or the other? It is estimated that more than 50 percent of the parts being made on Swiss machines do not require a guide bushing.

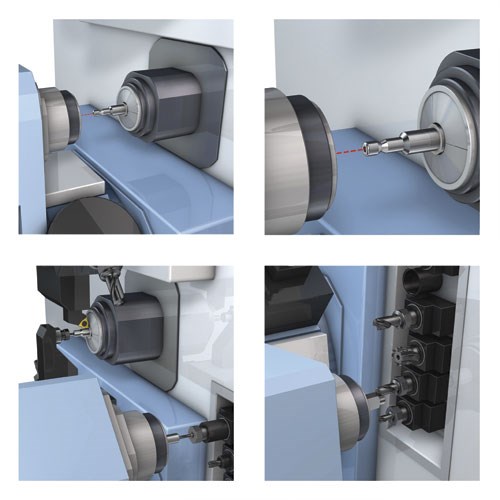

One option that can provide added flexibility in these cases is a machine that provides an interchangeable housing to allow operation with or without the guide bushing. A detachable housing carries a driven guide bushing and operates as a traditional Swiss-type. For non-Swiss parts, the guide bushing housing can be removed and changed to a sleeve. The spindle nose and collet have sufficient stroke to extend into the cutting zone.

Featured Content

No Guide Bushing

While the guide bushing on a Swiss machine serves a distinct, important purpose, it also brings along some baggage. Because it requires a tight fit on the barstock, the bar must meet a specific tolerance. This often requires the bar to be centerless ground before use.

The collet on a machine without a guide bushing, on the other hand, is more forgiving regarding diameter, allowing cold-drawn bar to be used without preparation. Hex and extruded stock can also be used when a guide bushing is not in place. And because additional barstock is not needed to cover the distance between the collet and the bushing, as much as 4 inches can be eliminated from the typical remnant.

Where a guide bushing is not necessary for stability of the part, it can actually create potential for inaccuracy. Without it, holding roundness is easier because the dimension is directly related to the accuracy of the spindle. Also, rotational speeds can be run higher for better production rates and surface finishes.

For the sake of machining functionality, a machine without a guide bushing allows multiple passes on a part; there is no restriction on the number of turning passes for roughing and finishing all the way up to the nose of the spindle. With a guide bushing, however, once a part is turned beyond the guide bushing land area, it cannot be retracted for multiple passes because the change in diameter no longer matches the ID of the bushing.

Making the Change

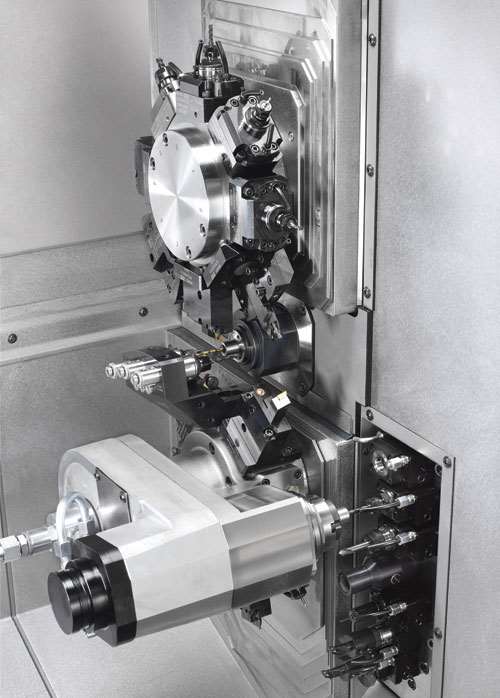

A single machine that provides the option to go with or without a guide bushing (without compromising machining capabilities) can open the door for much more scheduling flexibility on the shop floor. An important consideration for such a machine is the amount of time it takes to switch from one format to the other. INDEX TRAUB now offers the TNL18 sliding headstock automatic lathe, which can be changed over in a few minutes to produce long or short precision parts with or without a guide bushing. It is designed for long or short parts from bar of as long as 20-mm diameter, and by delivering precision and qualified surface finish in a single operation, it fits well in medical component machining applications.

The Z-travel distance of the headstock (205 mm with the guide bushing/80 mm without) ensures proper positioning of the main spindle in either setup. In the standard design, the main spindle is equipped with a C axis and uses either a direct drive with high dynamic response or a belt drive and high torque for larger cutting volumes.

A swiveling subspindle is fitted to an XYZ cross-slide, which simultaneously also carries the bottom tool turret. This slide, with ample axis travel distances, provides plenty of space for three-axis reverse side machining, even for geometrically complex workpieces.

Tooling

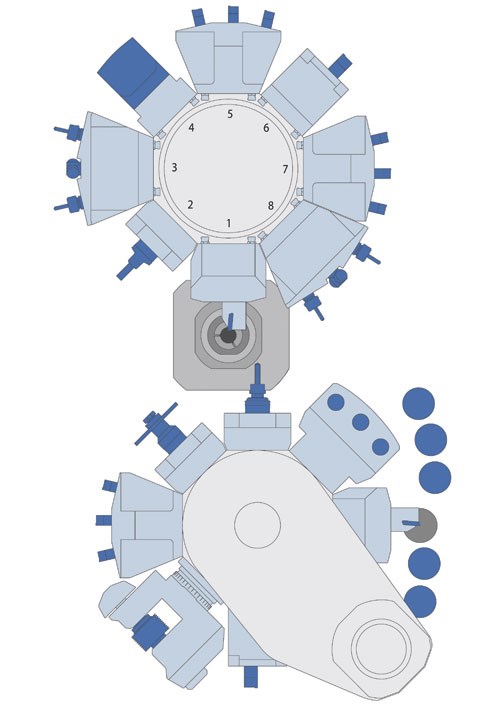

The rotating motion of the tool carrier is implemented as an NC rotary axis without mechanical interlock, allowing the angular positioning of the turret to be freely configured. All turret stations can be equipped with fixed or driven toolholders.

The machine features a backworking attachment that accommodates seven toolholders, three of which can be driven. In total, four stations are provided with an internal coolant supply. Each station can be controlled individually so that cutting oil is supplied selectively. The NC rotary axis of the turrets enables stations to be occupied by more than one tool.

The toolholders are seated deeply in the turret, resulting in less leverage effect for higher stiffness. For driven toolholders, the large shaft diameter enables insertion of roller bearings with large diameters. A quick-change system enables high-precision, smooth exchange of tools without removing the toolholder. The TRAUB compact shaft system is designed to allow toolholders to be mounted in the turret with more precision to help increase tool life and contribute to improved surface quality.

As many as three tools can be in the cut at once, and tool capacity can be increased to as many as 54 tools through dual- and multi-holders, extending productive times. Turret indexing speeds allow chip-to-chip times of less than 0.3 second.

Efficient Design

The machine is designed with a vertical bed, which promotes chip flow and provides a compact footprint. The electrical cabinet is integrated in the upper part of the machine for additional space savings. The sliding door to the work area has a higher and wider design to provide easier access for setup operations.

To address the needs of different applications, the machine is offered in two different variations. The TNL18P is designed as a production machine for customers looking to combine pricing and machining options for the sake of productivity. The TNL18 offers additional capability with seven linear axes (versus five for the production version), more headstock power and higher speeds. In the production version, the Y-axis motion of the upper turret is mapped by interpolation of the X/C/H axes, permitting contour milling and reliable off-center, axially parallel drilling.

Overall, both designs provide suitable options for shops that are looking to capitalize on the advantages of a machine that can be run without a guide bushing whenever the application demands it while maintaining the guide bushing when needed for accuracy on long, slender parts.

RELATED CONTENT

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

Swiss-Type Machines: More Than Just a Lathe

CNC Swiss-Type machines have more capability built in than ever before. Many of these capabilites can be accessed using attachments that increase the throughput of the machine tool, improve the quality of the work coming off the machine and reduce or eliminate the need for secondary operations even for very complex workpieces.