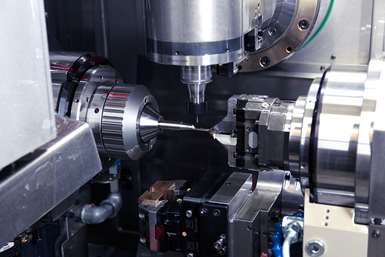

Mill-Turn Enables Multitasking, Single Setup Machining

Starrag’s Bumotec s191 mill-turn center can reduce lead times by completing a range of different tasks in a single setting.

Starrag’s Bumotec s191 mill-turn machine is capable of turning, milling, drilling, thread forming, grinding, gearcutting and broaching, all in a single setup. The machine can perform accurate (to ± 2.5 microns) machining tolerances within its X-, Y- and Z-axes measuring 410 mm, 200 mm and 400 mm, respectively, due to its linear drives and high-level thermal stability, according to the company.

Its main spindle is complemented by a subspindle that can turn in both horizontal and vertical planes. Tool magazine options extend to up to 90 pockets on a machine that has rapid traverse rates of 50 m/min and a 30,000 (or 40,000)-rpm spindle speed that also contributes to its fast cycle times.

The Bumotec s181 and s191 machines are available for rental, providing potential users with a cost-effective way to capitalize on the benefits of multitasking, single setup machining. The company says this enables customers to avoid relatively high upfront capital expenditure, yet immediately benefit from the machines’ ability to drastically reduce lead times by completing a range of different tasks in a single setting.

Related Content

-

OEM Moves From Automation Implementation to Refinement

Automating challenging parts for full-weekend automation requires substantial process refinements that can significantly boost throughput.

-

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

-

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)