Robots are gaining widespread acceptance and popularity for their material handling capabilities in loading and unloading parts into and out of machine tools and other manufacturing equipment. When a shop makes the decision to dive in and implement this technology, it faces some important questions. Here we will examine many of the basic details, such as where to buy articulating arm automation and what to know before the search for such equipment begins.

Robots

At the heart of the loading system is the robot, and many different brands, styles and choices can be considered. For the most part, this article will deal with the articulating arm robots that have become so popular in machine-loading scenarios. When a shop is looking to purchase such equipment, it needs to be sure it can handle the job as expected and consider the organization behind the robot. It is no secret that robots are an integral part of our automotive industries, which provide a great example of high levels of required support. A shop should consider robot brands that can provide this type of support after the purchase.

Featured Content

Different robots are designed for different kinds of environments. For manufacturing companies, it is important to select an industrial grade robot that is designed to work in the chip-covered, coolant-dripping environment that is normal in our machine tool loading world, and not something designed to work in a laboratory or food processing plant.

Robots are sized by reach and payload. The reach of the robot required is probably best determined by the team designing the cell. It is a function of the size of the cell in combination with where the incoming parts are coming from, where the finished parts are going to be placed and the available access to the machine being loaded and unloaded.

Payload is the amount of weight the robot can pick up, but this number can be a little misleading. Beyond the part weight itself, payload is the amount that a robot can lift, including all the tooling, grippers, adaption plates, extensions and so on that are mounted on the robot in order grab the parts. Additionally, this weight is stated from a specific point on the front of the robot. The further away from this point that the weight is located, the less weight the robot can handle. For a good rule of thumb, for most standard load/unload applications, only about half of the payload should be attributed to the parts. For a more definitive check on this, most robot companies have payload checking software to ensure that the payload is within the robot’s specification .

End of Arm Tooling

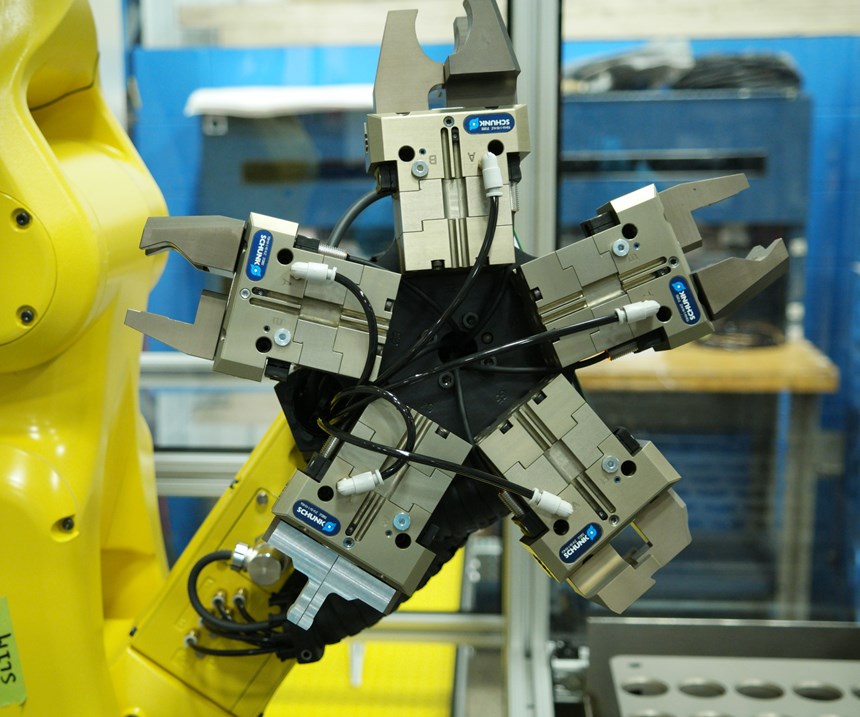

End of arm tooling (EOAT) is tooling that is mounted to the end of the robot to assist in performing the necessary tasks, such as parts movement. While various kinds of tooling, such as vacuum cups and magnets, are available for picking parts, the most common style on the shop floor uses pneumatic grippers. As with the robot itself, quality grippers that are appropriate for the working environment are important.

The application will dictate the size and quantity of jaws and grippers that will be needed. Grippers are available in many configurations and may have two, three or four jaws. Two-jaw, parallel-close grippers are the go-to grippers for anything square, rectangular or easily picked up between two fingers. Three-jaw grippers lend themselves to picking up round and hex parts, just as a three-jaw chuck is so prevalent on a lathe. However, for round and hex parts in a repeatable array, such as a tray set up with columns and rows of parts, four-jaw grippers often are more manageable.

Infeed/Outfeed System

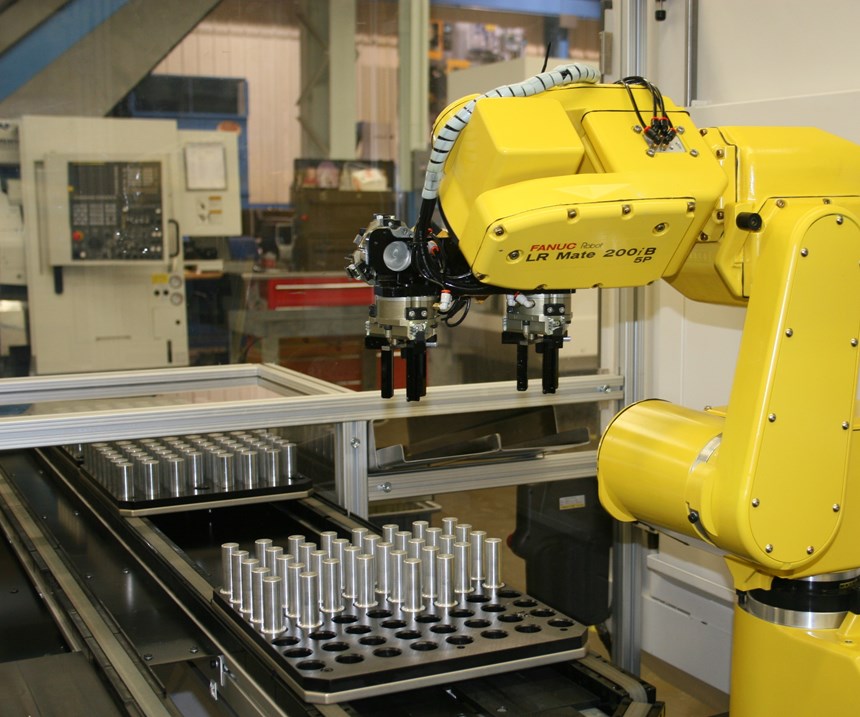

Infeed/outfeed is the term given to the method for bringing incoming parts to the robot or cell and moving finished parts away. The infeed system stores a number of parts in queue and brings those incoming parts to a repeatable place for the robot in preparation of being loaded into the machine. The outfeed system brings the finished parts away from the robot and out to the operator and will also store a limited number of finished parts.

Setting up an automation system requires many decisions, but one of the most important is the infeed/outfeed system. This system will be the point where the operator interfaces with the automation system the most, so making sure it supports what is needed is important. For instance, having the operator place parts in a specific orientation in a drawer is a good solution for lower volumes, but will be labor intensive when making many of the same parts, especially if the cycle time is short. The infeed and outfeed systems could be separate (for example, a vibratory bulk infeed system in and a chute out) or could be combined (for example, a drawer, where the operator places the incoming parts, and the robot takes the raw part from and places the finished parts back). The answers to the questions in this article’s sidebar help to better identify what setup will work best.

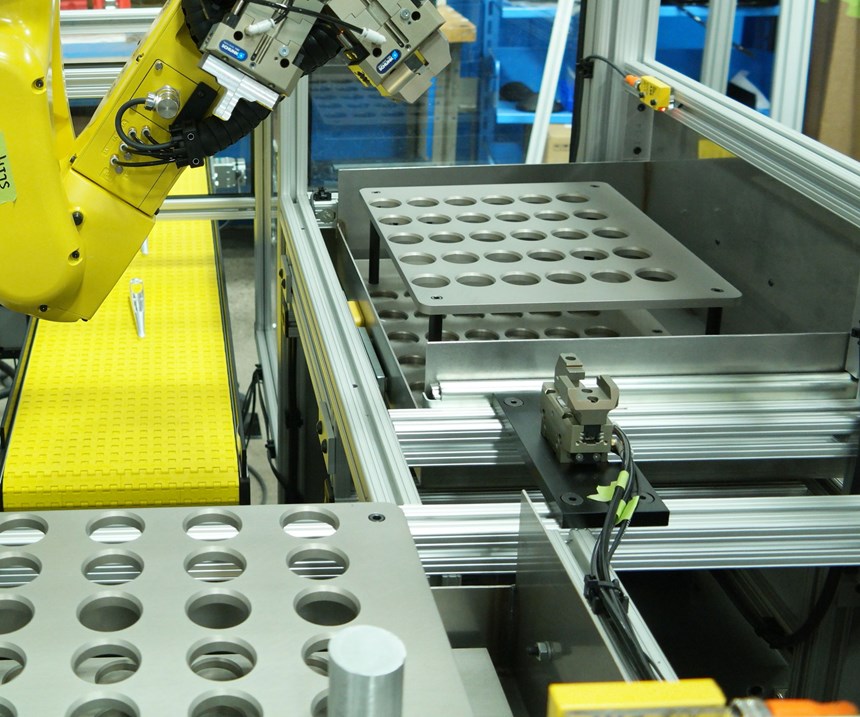

Drawers are normally attached to the side of the automation cell guarding and allow the operator a convenient interface with the automation system. Drawers have limited capacity, so a popular method is to have several drawers in a stacking configuration similar to those in a chest of drawers. The robot will pull open the specific drawer that it requires. When finished with the drawer, the robot will push that drawer back into the chest and pull out the next drawer to continue the process. Normally, there will be an insert in the drawer with a series of pockets in rows and columns to allow the accurate and repeatable positioning of parts so the robot will know where the part is for picking.

Conveyors also provide a flexible (and popular) method of bringing parts into and out of an automation cell. The conveyor may use adjustable lane guides and bring rows of parts to repeatable positions for the robot to pick from, or it could be set up in a configuration of moving multiple pallets of parts into and out of the cell when handling a large volume of parts. Conveyors are flexible and normally competitive on price, but when needed for large volumes of parts, their length requirements may create space issues in a crowded shop.

A chute is a good and inexpensive method of outfeed. The robot simply drops a part on an inclined chute to use gravity to bring it to a box. Not all parts can use a chute, as part damage is something to consider with this method.

Bulk vibratory infeed (bowl feeder or similar) is a great method for handling large volumes of parts. Almost no operator labor is required, limited to simply dumping a large bucket of parts into the bowl. These bulk feeders are not known for their flexibility and are usually designed to handle only a few similar parts.

Workholding

As with any non-automation job, how the part needs to be held for the machining operation is important, but when using automation, the machine workholding must now be automatic. Additionally, how the robot will be holding the part during loading and unloading is of equal concern so that the machine workholding and the grippers on the robot can work together. For instance, vise jaws often can be relieved or slightly modified to accommodate the robot gripper fingers that are holding the part.

Most lathes already have a hydraulic actuation system as standard, but workholding and workholding control are not normally part of a milling machine’s standard package. The workholding options on a milling machine provide similar advantages, whether automatic or not; vises, chucks and expanding arbors are all great choices, depending on the requirements of the parts. The bigger consideration relates to how the automatic workholding will be controlled (hydraulically or pneumatically).

A hydraulic system is more expensive to add to a machine, but will generate more force and tends to be a good general-purpose workholding control method. A pneumatic system will allow the gripping force to be discretely adjusted to accommodate delicate parts, but will not generate as much power (and, in turn, clamping force) as hydraulics.

Where to Buy

There are several different avenues to consider when buying automation. Articulating arm automation is normally built by an integrator that specializes in working with robots. Robots can be used in many different ways, so it’s important to make sure the integrator is knowledgeable in putting robots on machines. When putting robotics on a new piece of equipment, some machine tool companies have their own integration group that will handle the integration, and some use an outside integrator that they will direct most of their integration work toward. If the automation is to be added to an existing piece of equipment in the shop, the original machine supplier may be able to help. If not, independent integrators can easily step in to handle the installation.

Regardless of who will set up the system, it is important to have clarity on who will be responsible for what. When all of the equipment is purchased from a single supplier, it is clearly that company’s responsibility to make sure all of the different pieces of equipment are working correctly together. However, if the machine tool is supplied by one company and the robot from another, the lines of responsibility can easily be blurred. The difficult questions surrounding responsibility need to be asked up front to each of the vendors involved.

For more information about robots and automation from Methods Machine Tools Inc., call 978-443-5388 or visit methodsmachine.com.

RELATED CONTENT

-

The Effects of Automation on Manufacturing

Companies that are not currently using automation in their manufacturing processes should be considering it.

-

Automation in High-Mix, Low-Volume Turning Applications

Turning shops are familiar with automation for high-volume work, but the shifting landscape to smaller batch sizes has created new challenges.

-

Simplifying Machine Load/Unload Automation

Today, lower part volumes and frequent change-over are changing the offerings of some automation integrators. Standard, off-the-shelf components are being engineered to work together in a large variety of applications and, in some cases, are even portable so they can be moved from machine tool to machine tool.