Video Tech Brief: CNC Screw Machines a Solution for Overcoming Labor Shortages

CNC screw machines can exceed job shop productivity and enable manufacturers to overcome perpetual employment gaps.

#workforcedevelopment

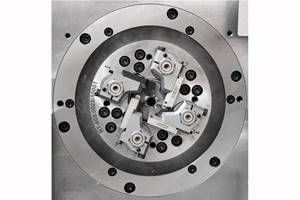

Automatic Lathe Maximizes Number of Operations in One Machine

PMTS 2023: Esco’s Escomatic D6 CNC Ultra automatic lathe makes it possible to machine the front and back of the workpiece simultaneously.

#PMTS

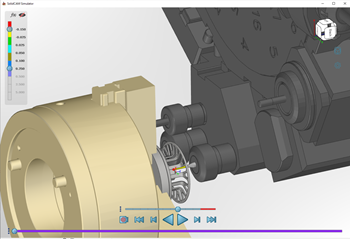

Multispindle Automatic Lathe With Full System Concept

PMTS 2023: Tajmac’s Penta TMZ 518 is a five-spindle automatic lathe that features an island concept which offers the machine as a package.

#PMTS

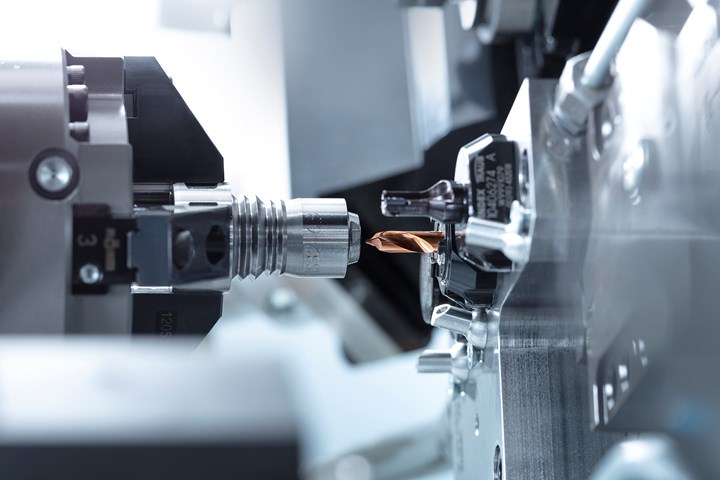

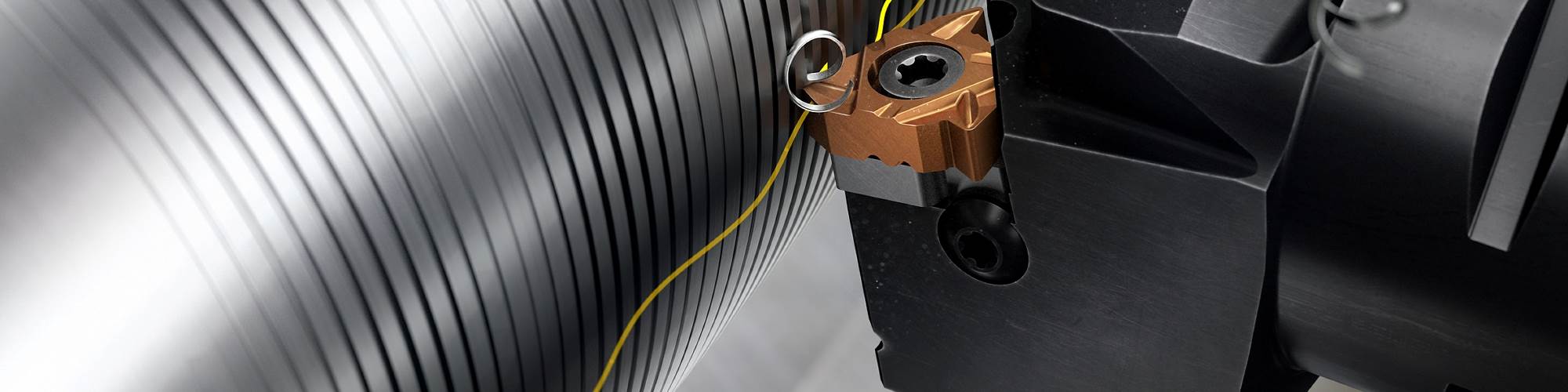

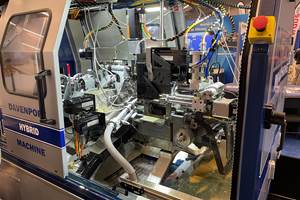

Bridging the Gap Between Traditional Single- and Multi-Spindles

This twin-spindle automatic lathe with six cross-slide mounted turrets is designed for medium-sized production runs that might not be suitable for conventional multi-spindles.

#techbrief