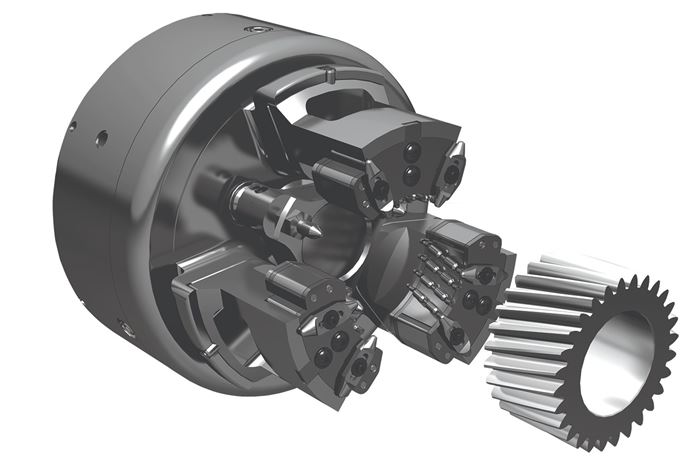

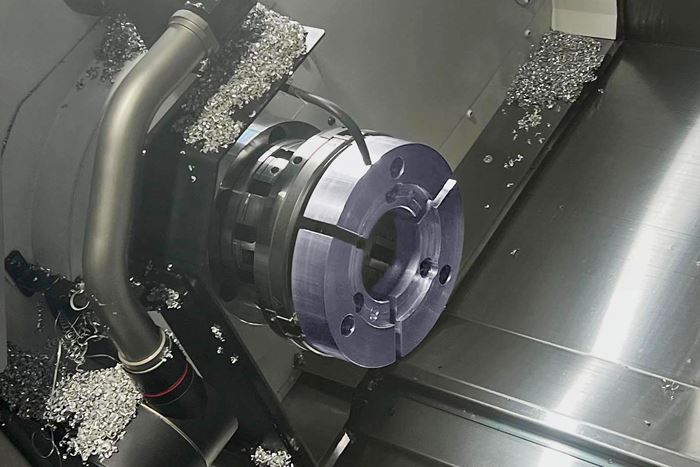

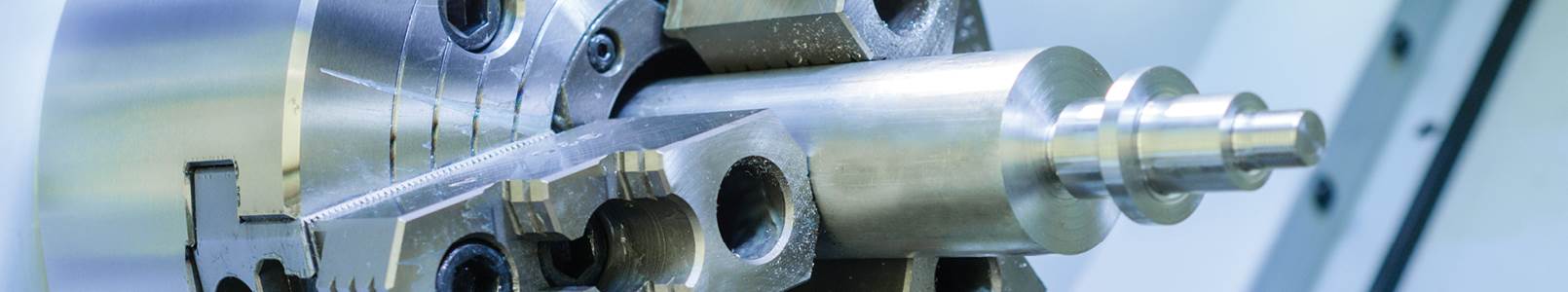

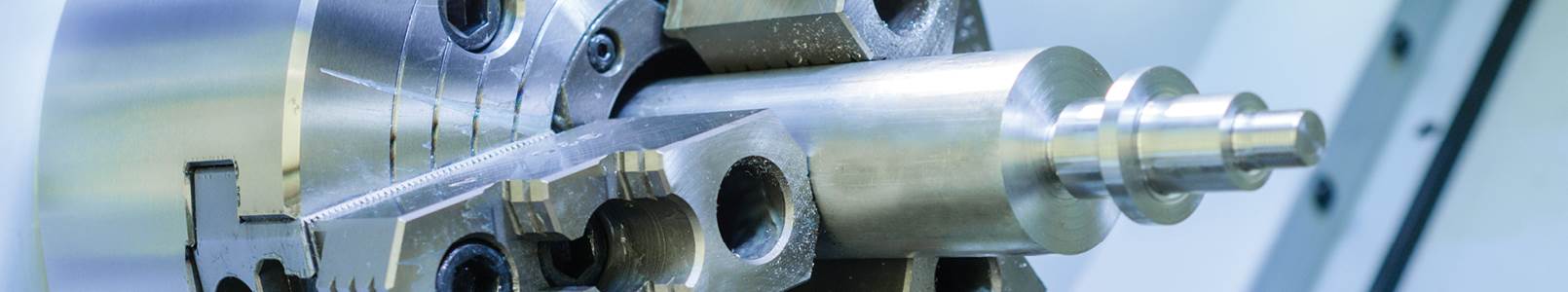

For turning centers, three-jaw chucks are the most common workholding device, gripping the outside of a bar or other type of material as the main spindle spins and turning operations are performed. For long parts, a tailstock with a dead center (doesn’t rotate) or live center (rotates with the workpiece) are used to support the opposite end of the workpiece during turning. Expanding mandrels are also available to expand inside a tube or machined bore to grip the part during turning. These provide the cutting tool full access to the entire outside diameter of a part. Quick-change collets are becoming more common to speed changeovers to new barstock sizes. A range of workholding options are available for milling machines, including vises, magnets, vacuum tables and hydraulic-actuated clamps.

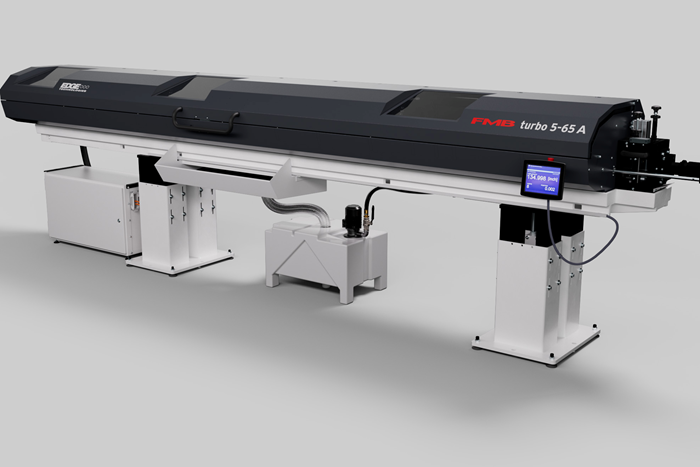

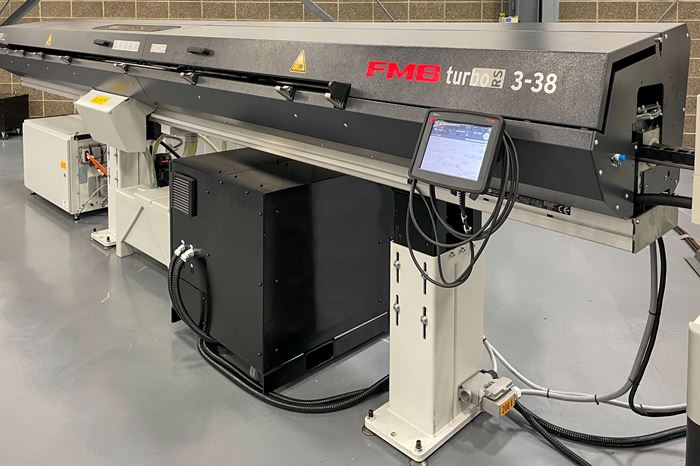

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

Workholding: Essential Reading

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

Discovering the Benefits of Collet Chucks

For shops making all types of parts, collet chucks can provide faster change-over, an increased gripping range, high rigidity and reduced maintenance.

Precision Workholding Delivers Accuracy and Production Capabilities

Holding the workpiece precisely is becoming an integral aspect of the machining process. It's more than presenting the blank to the cutter; it also includes repeatability from blank to blank.

Subspindle Workholding Options

The advent of subspindle turning operations has impacted throughput for many shops. Understanding workholding options available for backworking can help a shop make better decisions when specifying how to hold parts for op. 20.

Precision Workholding Offers Multiple Advantages

As American manufacturing continues to transition from the mass production of conventional parts to the manufacture of complex, high-value components in relatively small lot sizes, precision workholding has assumed increased importance

FAQ: Workholding

How does a three-jaw chuck work?

For turning centers, three-jaw chucks are the most common workholding device, gripping the outside of a bar or other type of material as the main spindle spins and turning operations are performed.

What is a mandrel?

Expanding mandrels are available to expand inside a tube or machined bore to grip the part during turning. These provide the cutting tool full access to the entire outside diameter of a part.

What is a collet?

Collets are generally used when the diameter of the part or bar to be gripped ranges from 1/16 inch to 2.5 inches. Compared with standard triple-jaw chucks with soft jaws, standard collets tend to be inexpensive and more accurate for gripping in the small-to-medium range.

When a collet-type workholding device is used, the part being gripped and machined will be closer to the headstock bearings on the machine tool or indexing fixture than is the case when using a power chuck.

Source: Collets Vs. Chucks

How do you use a vise?

According to Mr. Wolfe, "any vise has a bending moment associated with the clamping force applied. Take for example a 6-inch vise held down by its four corners. When the vise jaws close to clamp on a workpiece, the unsupported middle will tend to bend up from the machine table. It can move 0.002 inch or more. On precise parts that may be all the tolerance there is. My suggestion is always to secure the vise base as close as possible to the center distance between the movable and fixed jaws."

Another problem for many shops is consistency from operator to operator. "Rarely do two operators use the same clamping force on a vise," says Mr. Wolfe. "Deflections of the workpiece blank can cause inaccuracies. A more expensive but more accurate pull-type vise will help reduce some clamping variability. A simple torque handle will help achieve consistent clamping on both the pull-type and the more common push-type vises."

Make it a rule of thumb," says Mr. Wolfe, "to always try to keep the workpiece as close to the vise base as possible. Usually parallels work better on this type of setup than step jaws because the operator can check the seat of the part by trying to move the parallel. If it's snug, it's good."

Source: Flexibility Is A Vise

Workholding Suppliers

Narrow by Workholding Category

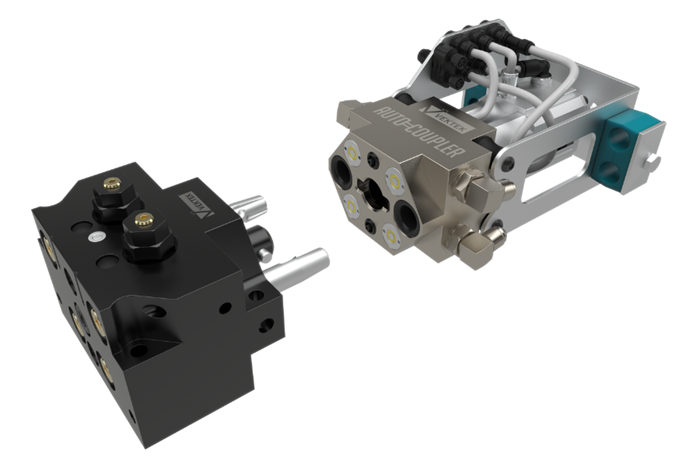

- Actuators, Hydraulic & Pneumatic

- All Other Workpiece Handling, Loading & Feeding Equipment not specified

- Angle & Sub Plates

- Arbors, Expandable Workholding

- Centers, Live & Other

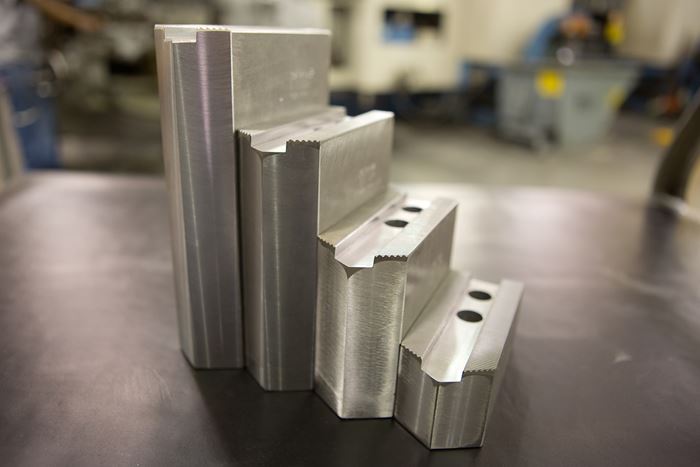

- Chuck Jaws & Collets

- Chucks, Collet Type (for Workholding)

- Chucks, Diaphragm

- Workholding, Custom

- Vises & Vise Jaws

- Steady Rests

- Pedestal Type Fixtures & Tombstone Blocks

- Mandrels

- Guide Bushings (for Swiss Lathes)