Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

#basics

Bar Feeder for Sliding Headstock Lathes Enables Higher RPMs

PMTS 2023: The LNS GT 342 automatic magazine bar feeder is designed to enable fast and easy diameter changeovers and improved productivity.

#PMTS

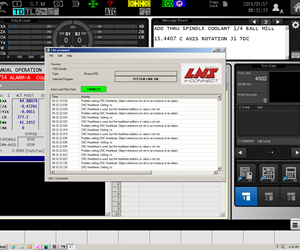

All-Electric Bar Feeder Optimized for Lights-Out Production

IMTS 2022: The Quick Load Servo 105 automatic bar feeder has a 26" (650 mm) heavy-duty magazine which can stage up to 1,430 lbs of barstock for long unattended and lights-out production runs.

Magazine Bar Feeder Enables Unattended Operation

IMTS 2022: Edge Technologies’ Commander 8-80 magazine bar feeder enables unattended operation with its large magazine capacity.