Bar Feeders And Workpiece Surface Finish

Quality surface finish of a part is not only dependent on the turning machine itself, but also on the barstock loading and support system. The bar feed system becomes critical to the surface finish outcome by enabling the turning machine to create the desired finish and/or by protecting the existing finish.

Every step in the machining process has an impact on the surface finish of a workpiece. Of course what constitutes acceptable surface finish depends on the nature of the part and its application. Regardless, virtually every part has to meet some surface finish criteria. In many cases a part begins as raw barstock and the surface produced by the turning machine will be the final finish. In other situations the part moves on to additional machining processes that may refine the surface finish. Or the barstock may be chromed or otherwise pre-finished before the turning operation begins.

With increased pressure on productivity and in these days of lean manufacturing, no one wants to add steps to their process because the surface finish was marred during the turning operation. However, what some manufacturers overlook is that the fate of a part’s surface finish rests not only with the turning machine itself, but also with the barstock loading and support system. In fact, the bar feeding system becomes critical to the surface finish outcome by enabling the turning machine to create the desired finish and/or by protecting the existing finish.

Perhaps the most powerful role that a good bar feeding system plays in protecting a part’s surface finish is that of eliminating harmful vibrations caused by barstock rotating at today’s increasingly higher speeds. If this vibration is not controlled, it can be transmitted through the spindle, through the part and into the cutting area, where it will affect the precision of the cut and degrade the surface finish. Although containing vibration seems simple and obvious, it’s actually a complex matter that involves a number of issues:

Hydrodynamics: The hydrodynamic principle of bar feeding, available from LNS, uses oil to evenly support the barstock, thus greatly reducing vibration. Within the bar feed chamber, the barstock rotates without touching any solid surfaces, eliminating the danger of marring the bar’s surface. Naturally, the barstock and the oil in the bar feed must be kept free of grit, metal shavings or any other debris that could be churned up as the bar rotates, damaging the surface.

Guiding Channels: Using the correct guiding channel size allows the hydrodynamic principle to work most effectively to reduce vibration. Therefore, a bar feed that is designed for quick and easy change-over from one guide channel to another will minimize the need to run too wide of a range of barstock diameters within one channel. Guiding channels made of a non-marring material such as polyurethane, instead of steel or plastic with steel inserts, will help to reduce scratches to the workpiece surface.

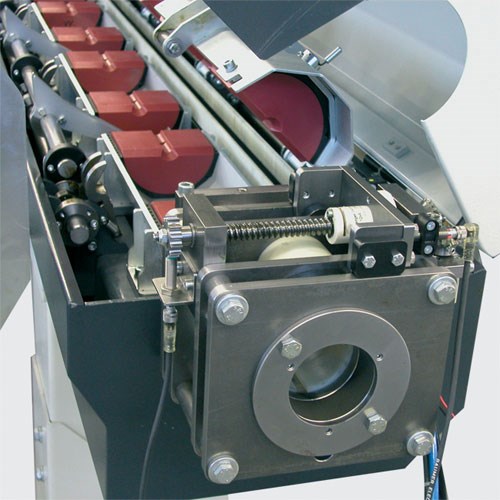

Front Stabilizers: No matter how well a bar feeder supports a 12-foot length of barstock, a small amount of vibration is likely to remain. A front stabilizer built into the bar feeder applies a hydrostatic “fix” for this remaining vibration by trapping the bar in an oil-fed, clamp-like device. This clamping area also must have non-marring surfaces, such as polyurethane, to protect the workpiece.

Spindle Liners: One-piece spindle liners specifically designed for the lathe headstock can help to maintain a better surface finish. Spindle liners are sometimes created on site by putting a series of smaller pieces together. This practice may produce misaligned joints that will scar barstock as it feeds through, generating vibration by offsetting the bar in rotation. In some applications, such as cutting chromed barstock, LNS treats the inside of the spindle liner with a special coating that gives it a low coefficient of friction to further protect the workpiece surface. This coating also prevents metal chips from embedding themselves in the walls of the liner where they would be trapped between the spindle liner’s ID and the bar.

Chucks: Although the bar feeder may eliminate vibrations through hydrodynamics and by use of a front stabilizer, an improperly sized or loose chuck will allow uneven barstock rotation to create new vibrations and mechanical damage to the part surface. Therefore, it is imperative for the chuck to properly hold the workpiece. Collet chucks can hold their clamping accuracy over long runs and, therefore, can eliminate vibrations longer than three-jaw chucks.

Unloading The Part: Once the turning machine has completed its cycle, the workpiece must be removed without harming the surface finish. In some cases, robots, gantry loaders or other automated picking devices may be able to remove the workpiece successfully, although they increase overall cycle time. Another option is a vacuum-type unloader, such as the LNS Blaze Air. This automatic unloader vacuums parts out of the turning machine spindle and onto a nylon-covered tray in 2 to 3 seconds. For chromed or other highly-finished parts, all of the internal components of the Blaze Air that touch the part are treated with a special coating to protect the workpiece surfaces from marring.

Taking these issues into consideration helps to protect the surface finish of parts without slowing down production or inhibiting productivity.

Read Next

Line Your Spindles, Line Your Pockets

Urethane spindle liners present a viable option to steel to fill the gap between spindle ID and bar OD. They protect both the spindle and bar stock and increase machine performance.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read More