Medical Machining is in the Genes

Appears in Print as: 'Bitten by the Bug'

Sometimes it’s difficult to stay away. This company is an example of a precision machining family that simply can’t stop doing what it does.

Although Medical Device and Implants (MDI) a Lancaster, Penn., manufacturer of medical devices and orthopedic implants, was established in 2012, it has a pedigree. What would become the progenitor of MDI began in 1962 when a young lady named Mary Burton started her first screw machine shop after getting bit by the metalworking bug. She still has the bug and passed it on to her son Ed, MDI’s company president.

According to Mr. Burton, back in 1962, his mom was a 19-year college student. Under the tutelage of an immigrant Swiss machinist, she became fascinated by the process and products these Swiss-type automatic screw machines could make. In her, he recognized a unique combination of machining ability and entrepreneurial drive.

Featured Content

From then on she never looked back. Through persistence and her obvious passion for machining, Mrs. Burton early on, was able to overcome doubts that a young woman could do the job.

Her first company was named HDJ, and from the start was focused on the manufacture of components for the energy industry and the nascent computer industry, finding work from companies such as Union Carbide and HP. Later, she directed HDJ toward the medical device industry and eventually morphed it into an OEM by finding better ways to manufacture and assemble complete medical devices. Early on, she beat the “boys” at their own game.

In her long career, Mrs. Burton has been recognized by the medical device industry several times, including awards from MD&I as well as the precision machined parts industry, whose association, the PMPA, presented her with its prestigious Gold Micrometer award in 2008 for 40 years of service to the industry.

Medical was an ideal blending of the company’s competency of precision machining combined with engineering and complemented by investment in a FDA Class 10,000 clean room for assembly of complete medical components. While this investment augmented the electronics business, which also demanded clean components, it allowed them to do medical work that only a few shops at that time were capable of.

Mrs. Burton’s plan was to move the company beyond just supplying discrete parts. She wanted to make, assemble and package complete devices, and use the company resources and its nimble size to compete with the industry heavy weights.

New Company, New Technology

After a hiatus from its second company, SMD (Specialized Medical Devices) started in 1996, Mrs. Burton and Mr. Burton had a chance to start MDI and apply the experience accumulated in HDJ and SMD to a new venture. MDI represented a unique opportunity in that the Burtons, who had sold SMD, were starting from scratch. This was a chance to do it all over again and apply lessons learned from previous experience.

They renovated a 15,000-square-foot space in Lancaster and went shopping for capital equipment—all new. What’s a bit different with this family enterprise is its collective experience.

Unlike many companies, which often learn “on the job” and upgrade older technology as time goes by, the Burtons knew exactly what they needed to make a medical device manufacturing machine shop go and understood that current technology, especially CNC, is the most efficient and with the right people, most competitive. MDI was the opportunity to apply a lifetime of knowledge.

When Mrs. Burton began her metalworking career, screw machining was an easily defined branch of the metalworking tree. According to Mr. Burton, early on, his mother understood that to differentiate the business from every other screw machine shop, it was necessary to do more than just precision turning. This meant looking at not only new machines, but new process technologies.

It’s a philosophy she carried into the new venture. Barely 2 years into the mission, MDI is ISO 13485 certified, and after starting with 18 employees in 2012, is now up to 32 people. The shop floor is divided into distinct operational departments that work in titanium, stainless, cobalt chrome, platinum, PEEK and other exotics.

What it Takes

Manufacturing small parts for the medical industry is often a different animal than many other industries. Even in a medical parts production environment, job lots are generally smaller, with tight delivery requirements, more demanding materials and complex designs.

Tooling and processes need to be closely suited to achieve the results necessary to meet the high quality requirements. In the case of MDI, much of their discrete parts metalworking is making poly-axial bone screws, flat or anatomic plates, and straight or pre-bend rods for spinal and small-bone implant orthopedic systems.

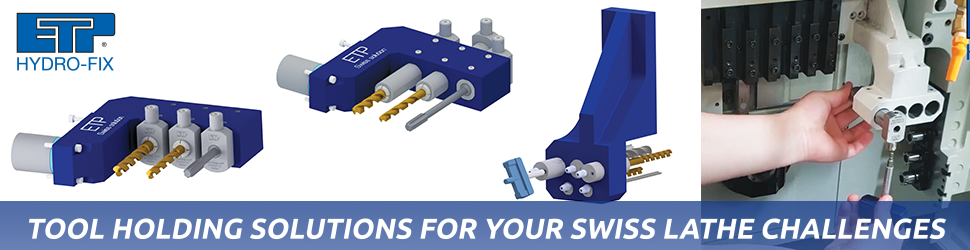

However, because of Mrs. Burton’s experience in dealing in the medical industry in her long career, the need to do more than just parts is a key to success. Like many shops, MDI relies on the versatile CNC Swiss-type machine for much of the turning and multitasking operations needed to produce orthopedic parts such as bone screws and plates, but that’s just the beginning.

In addition to metalcutting expertise, the shop has also installed a variety of other processes to ensure full service to its medical customers. These processes, all in-house, include anodizing, passivation, packaging, laser marking, electropolishing, EDM and a Class 100,000 clean room, in addition to four- and five-axis machining center capability. Being a full-service supplier to the medical device industry is the company’s hallmark.

According to Mr. Burton, as in so many industries, medical customers are looking to reduce the number of vendors they contract with. This puts pressure on suppliers such as MDI to do more for them in order to keep the business. As a result, the variety of process capability continues to become more and more varied, which is leading shops such as MDI to become more vertically integrated to maintain quality control and delivery flexibility.

Skin in the Game

One of the services that MDI provides to its customers is what Mr. Burton calls an inspection plan. Because of the experience of the employees and the breadth of equipment available to verify and validate the work the shop does, it’s able to become an extension of the customer.

It does this to the point that often MDI’s inspection data becomes part of the customer’s FDA product file. That represents an exposure for MDI, but because of the company’s experience and confidence in how it operates, the risk is minimal. Moreover, it represents a value-added service that many suppliers are less than willing to undertake. Call it a competitive edge.

Mr. Burton credits his mother’s many years in the industry with instilling a sense of confidence in the employees and giving support to the processes the shop uses by providing the willingness to accept responsibility for the products that go out the door. In effect, he says, “We become a partner with the customer, and with the shared liability risk, our employees are highly motivated to get it right.”

It can take 1 to 2 years for a new vendor to qualify as a supplier of implants. But because of Mrs. Burton’s history and reputation within the industry from her previous companies, this process has been shortened somewhat for MDI. The company, like most, must continue to prove itself every day and with every shipment, but this company knows how to do that.

Shop Capability

“When our previous company was purchased, the new entity moved the operation to Wisconsin,” says Mr. Burton. “Many of the employees stayed in the Lancaster area and were able to find other work in the area. Upon hearing that we were starting a new venture, focused on the manufacture of orthopedic systems, many of our former employees came back to us and populated MDI with veteran machinists, QC inspectors and manufacturing engineers, many of whom have worked together for more than 20 years. It was like having an instant experienced shop and really helped get MDI off to a good start.”

The Swiss department has four Citizen CNC sliding headstock machines, which are seven-axis machines capable of holding tolerances of ± 0.0001 inches. The shop uses these for its turning operations, thread whirling of bone screws, micro-hole drilling, milling and slotting.

In its milling department, MDI has four Haas vertical machining centers, three of which are five-axis capable for complex work. Three machines, two five-aixs and a four-axis, are devoted to machining metal. A fourth machine, a five-axis Haas VF2, is dedicated to non-metal workpieces, such as parts made from PEEK since these parts are machined dry.

For intricate shapes, precise forms, tooling and fixturing for other machines, MDI uses a Fanuc OiE wire EDM machine. It is capable of cutting slots as small as 0.007 inch wide and internal radii down to 0.0035 inch. It can also produce surface finishes up to 13 rms.

The finishing department at MDI is equipped to provide in-house services to complete its machined parts to specification and reduce the need for additional outside vendors. Tumbling, ultrasonic cleaning, anodizing, nitric passivation, laser marking and electropolishing are some of the capabilities available for finishing machined parts. Some of these operations are performed in MDI’s Class 100,000 clean room.

“In today’s medical device industry,” says Mr. Burton, “one of the reasons it’s difficult to break into it is because before you can even begin considering making implants, the shop must have a working quality system that satisfies the FDA and the orthopedic community.” In effect, you must prove yourself to the FDA before you can prove yourself to a customer.

Mr. Burton says, “Because our reputation as a supplier carried over to MDI, one of our customers had enough faith that we would pass the ISO audit certifying us as ISO 13485, meeting FDA standards to qualify for implants, which we did in early 2013, they gave us a nice order that basically put us in business again. That relationship continues, and as the customer grows, so do we. It’s about collaboration.”

Orthopedics on the Rise

MDI’s specialty of implants for small bone and spinal surgery is on the rise. As boomers age and Americans pursue a more active lifestyle, Mr. Burton likes the position is which his shop finds itself. “With this new startup, we are a more focused business and can devote our energy and expertise to doing what we do best—making implants,” he says. “ The industry demands continuous innovation. We know how to do that and have the infrastructure in place to make it happen. I’m bullish on MDI’s future, in large part because of where we’ve been.”

— Marubeni Citizen-Cincom Inc.

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.