Craftsman Cribsheet No. 104: Common Applications of CNC Machining

Provided by W.H. Bagshaw Co. Inc., Nashua, New Hampshire

Computer numerical control is one of the most versatile manufacturing methods, capable of producing parts and components with dimensional accuracy and complex geometries in varying quantities from a wide range of metallic and non-metallic materials.

Industry Applications for CNC Machining

Photo Credit: PMPA

Aerospace

“Cannot fail” precision components are expected in the aerospace industry, and CNC machining processes are part of the means of production chosen by aerospace manufacturers as part of their quality systems to ensure components meet all requirements for precision and that properties comply with all requirements.

Photo Credit: PMPA

Photo Credit: Photo Credit: PMPA

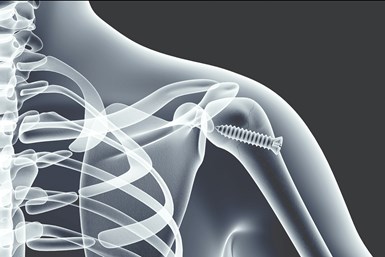

Medical

Like aerospace, medical device manufacturers produce components where precision, accuracy and consistency can be a literal matter of life or death. CNC machining is a critical process that creates complex, quality parts from medical-grade materials. Medical is one of the largest markets served by CNC machining.

Automotive

CNC machining is popular with the automotive manufacturing industry for its compatibility with both metals and plastics, fast turnaround times, and consistency/repeatability, all of which make it the perfect option to produce large volumes of critical parts.

Photo Credit: PMPA

Electronics

From the inner workings of a smartphone to electrical enclosures, CNC machined parts are found in almost all consumer electronics, industrial electronics, electronic components and more.

Defense and Sporting Arms

Manufacturers in the defense and sporting arms industries require incredibly precise and robust parts made from high-performance materials capable of withstanding significant wear and tear — a call to arms to which only CNC machining can respond.

In today’s modern world, “cannot fail” is an expectation in nearly every market and application. CNC machining provides a consistent, repeatable process for producing highly engineered, complex components for these critical applications.

Related Content

-

Predicting the ROI of Robotic Automation

Various methodologies paired with online tools can help small to mid-sized manufacturers determine how to predict and calculate the potential economic benefits of robotic equipment for their specific needs.

-

5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

-

Know Your Knurling

Understanding some knurling basics will enable you to choose the proper tooling system based on application requirements.