Energy-Efficient Machine Tool Technologies for Any Size Shop

Recognizing that advanced machine tool technology can be used as a highly effective energy-saving tactic, Okuma offers ECO Suite to reduce power consumption.

In individual shops across the Americas, rising energy costs are causing concern as they chip away at profits. Recent numbers show even more cause for alarm. In January last year, One Voice, the government advocacy program for the National Tooling and Machining Association (NTMA) and the Precision Metalforming Association (PMA), polled metalworking companies about their energy expenses. Responding companies had an average of 67 employees and reported average annual energy costs of $184,588. Overall, 66 percent of the respondents expected an increase of 11.67 percent ($21,541) that same year. Considering such dramatic increases, shop owners need to find ways to keep energy costs down.

Globally, this issue is being addressed. Both Canada and Japan currently offer rebates for the purchase of equipment that includes energy saving features. This is great for users who benefit from both the rebate and the ongoing savings on energy expenditures. One Voice reports that large manufacturers are also implementing cost-saving features such as changes in lighting systems from older “yellow” fixtures to more efficient and brighter white lights. Many have also invested in new HVAC systems with the help of state tax credits. But machine shops of any size can control their own destiny by adopting more energy-efficient machine tool technologies.

Featured Content

Addressing Hidden Costs

CNC machining processes contain hidden costs that often go unnoticed. Machine tool idling, unnecessary pump rotation and continuous running of peripheral equipment are all energy guzzlers that, when managed, can provide significant savings. Recognizing that advanced machine tool technology can be used as a highly effective energy-saving tactic, in 2015, Okuma released its ECO suite technology as a part of the OSP suite.

ECO suite is a next-generation system that saves energy by reducing the power consumption during both machine operating and waiting times. It includes four intelligent control applications that save on unnecessary energy expenditures, leading to potentially dramatic results.

System Features

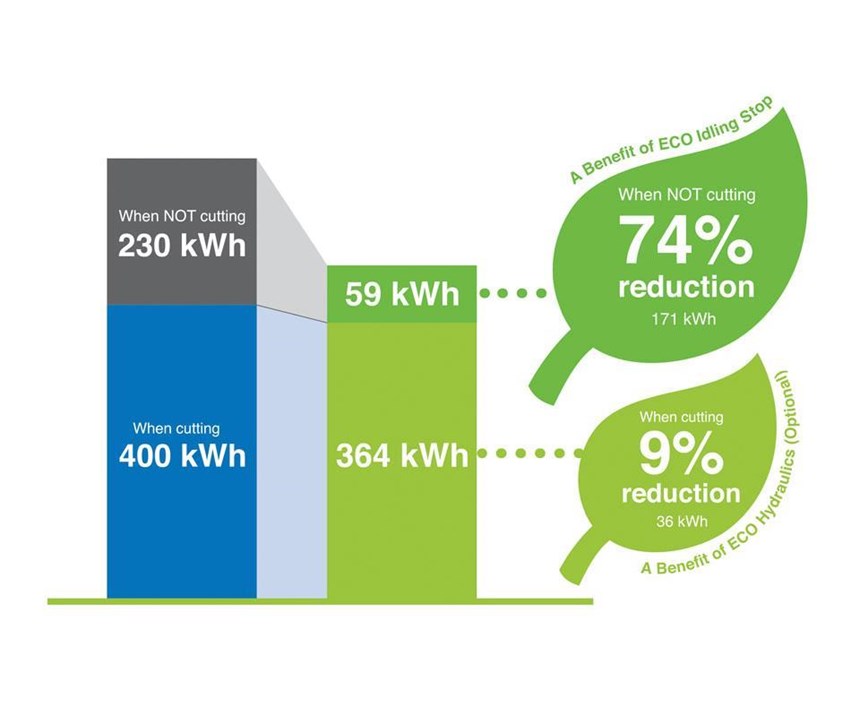

ECO Idling Stop is an application designed to stop machine tool idling. This energy-saving system uses Okuma’s Thermo-Friendly concept to monitor the cooling status of the milling and turning spindle, automatically turning off the coolers for these spindles when cooling is complete (Figure 1). While the system carefully stops peripheral equipment, the benefits increase with longer machining preparation times. The result is substantially decreased power consumption when the machine tool is not cutting (Figure 2).

ECO Power Monitor allows the operator to see how much energy is being saved right on the machine tool’s display. Power consumption is shown for spindles, feed axes and peripheral equipment. Energy savings achieved can also be viewed by using ECO Idling Stop to manage peripheral equipment (Figure 3).

ECO Hydraulics is an optional feature designed to provide accurate control, even at a low rotation speed. It minimizes unnecessary pump rotation during dwell pressure applications. Pump rotation is optimized to match operating status by combining the servo control technology on the machine tool with high-efficiency hydraulic pumps. The result is a significant reduction in power consumption.

ECO Operation permits peripheral equipment to run only when needed, and only for the duration required. Equipment such as chip conveyors and mist collectors are automatically stopped after cutting is finished.

Further Savings

Taking energy savings a step further, many of Okuma’s CNC machines (CNC lathes, the LB EX series of horizontal lathes, and the Multus series of multitasking machines) are equipped with the company’s Prex motor. These built-in reluctance motors, incorporated into the spindles, have numerous slits in the rotor to make generation of reluctance power more efficient. The rotor structure has a small amount of interpolated permanent magnets to increase performance. Designed to be more efficient than induction motors, the Prex motors feature high torque in typical turning ranges to raise the system efficiency by 4 to 9 percent.

These compact motors have low mass in the rotating section that reduces inertial mass by 47 percent, according to the company, making acceleration and deceleration highly responsive. Overall, energy consumption can be reduced by as much as 13 percent.

Applying the Savings

Shops of any size can benefit from a number of opportunities for energy efficiency that can lower energy bills and allow those savings to be applied in more constructive ways. Increases in profitability allow further investment in new equipment and technology as well as additional staff for continued production growth.

Here's more information about the ECO Suite energy saving system.