In 1937 John Cupler was working at a textile plant and came up with a better way to make drills that could produce very small holes used in the production of spinnerets used in the fiber extrusion process. The result of Mr. Cupler’s innovation was the founding of National Jet Co. (LaVale, Maryland).

From its inception, demand for the company’s small hole production capability was strong. Literally and figuratively a narrow niche, its specialty focus has propelled the company to a global position as a “go-to” source for micro-hole making used in precision flow applications and, as a result, has opened additional, more conventional manufacturing opportunities.

Featured Content

In addition to designing and producing drills for micro-hole making, Mr. Cupler built machines for production of the small holes. These are manual machines, and the shop uses them today for prototype development of new tools and limited quantity production.

The operator skill level for these machines is quite high. Making holes 0.001 inch with a microscopic tool on a manual machine requires a deft touch. The Z-axis feed arm for these machines is balanced to a point where its sensitivity allows an operator to “feel” when a drill is dulling.

Our host for the shop visit to National Jet was Chuck Condor, the company’s sales manager. He and Ben Odom, the company’s general manager, have overseen the business’ evolution from a specialty, micro-hole vendor to a full-service contract machine shop that does micro-hole production well.

“For many years, our micro-hole making ability was the draw for getting work into the shop,” Mr. Condor says. “Customers, often other shops, would send in parts for National Jet to machine the holes needed to complete the workpiece. In the last decade, we’ve added capability to provide full service machining and that has won us jobs that we manufacture complete. It makes sense for our customers to deal with a single source.”

The 26-employee company has augmented its micro-hole making capability with CNC vertical and horizontal machining centers, wire and ram EDM, and CNC Swiss turning, which provides additional machining capability. Mr. Condor says even jobs that National Jet machines complete almost always involve a small hole feature on the part geometry. It’s the company’s specialty.

The Flow Must Go

True to the company’s roots in the production of fiber spinnerets, many of the jobs that National Jet produces require precise and repeatable orifices that control flow rates of liquids or gases. It still does many jobs for the fiber production industry, including extrusion dies.

“We’ve been doing a lot of work producing nozzles for the 3D printing industry, and medical is another important customer base,” Mr. Condor says. “Any applications where precision flow control is required are where we do well.”

Key to successful production of these small-hole flow dependent parts are that they must be burr-free. Microscopes dot the shop floor at workstations where 100 percent inspection of drilled holes is performed in search of burrs.

Any burr in the flow path that National Jet makes can deflect the liquid or gas in a negative way and inhibit its consistent deposition. Inkjet nozzles, for example, are sensitive to burrs. “If there is a burr in the path of an inkjet nozzle, for example, the ink will ‘dogleg’ and not go where it is aimed,” Mr. Condor says.

“Because we make our own drills, which have a tolerance of +0.0000 to -0.0001 inch,” Mr. Condor says, “sometimes we can design a geometry that mitigates burr formation. However, for the most part we must detect and deburr the small parts we make. Deburring is labor intensive, but critical to our success. In addition to microscopes, we have optical gages, some quite sophisticated, to help ‘see’ the burrs so they can be removed. We have zero-burr tolerance in this shop.”

The base material for textile spinnerets and extrusion dies is hardened 17-4 stainless, usually in round or rectangular bases. With its machining center capability, National Jet can machine the bases and add the micro-holes to deliver the job complete. These dies may have a few or thousands of micro holes depending on the die’s application.

One Person’s Small

Every company of any longevity has its stories. After 82 years in business, National Jet is no exception. One story I was told during my visit involved the company’s founder, John Cupler.

Some years ago, long after Mr. Cupler was established in the micro-drilling field, an overseas drill maker sent him one of its drills that was being touted as the “world’s smallest,” asking if he could make a drill that small. Mr. Cupler answered by drilling a hole in the world’s smallest drill and returning it to the sender. Enough said!

For National Jet, its working small hole size range is 0.001 to 0.02 inch. They can make smaller holes, but that range is practical for production consistency.

The drilling techniques the company has developed using its manual machines are transferred to the CNC machines used in production. Pecking routines are used for almost every small hole drilling operation and are cut “wet” using a light cutting oil. The CAM software used on the CNC machines is programmed to emulate the micro-drilling techniques used on the manual machines and on some jobs, the Swiss machine, for example, can be set up to run unattended.

The company has accumulated an extensive database of cutting tool feeds and speeds for a starting point for most applications. “We have found through the years, conservative feed and speed rates we can be successful for most of our micro-drilling operations,” Mr. Condor says.

According to Mr. Condor, depth of cut is generally the limiting factor for small-hole drilling. To hold a tolerance in the 0.001-inch diameter range, a length-to-diameter ratio of 7 to 1 is a safe bet for the micro-drills National Jet makes for use in production volumes.

EDM as Plan B

National Jet produces its micro-holes using drilling when possible. Generally, the drilling process is faster, and the tools can be adapted to the shop’s machine tools, including its Swiss-type lathes and machining centers.

However, there are some jobs National Jet has found through experience that can be better produced using EDM. Some micro-holes can’t be produced any other way.

EDM is a non-contact process that removes microscopic “chips” from a workpiece blank using an electric spark to erode metal. Wire and ram (die sinking) are the two types of EDM, and National Jet uses both in some of its micro-hole making applications.

Probably the biggest advantage of EDM over drilling micro-holes is that the process is burr-free. “For applications where the part geometry is too complex to allow access for deburring, we will EDM the micro-holes to avoid the possibility of any burrs,” Mr. Condor says.

The EDM electrode or wire can produce holes of 0.001-inch diameter. Because the EDM process erodes the material it is machining, calculations are needed to allow for clearance between the electrode and the part.

One example Mr. Condor cites is that for a 0.0068-inch diameter hole, the EDM electrode might be made to a spec of 0.0062 inch for swarf clearance and to maintain the electric arc gap. Test cuts are then performed to determine the optimum diameter, and tweaked up or down to meet the final tolerance specification.

Another application that National Jet uses EDM to machine small holes is material that is hardened. “We make a lot of core pins for the textile dies we produce,” Mr. Condor says. “These can be 40 and above on the Rockwell scale and burn through cutting tools rapidly. EDM is more cost effective on these harder materials.”

Because many of the micro-holes that National Jet produces are sensitive to material flow, some applications specify that the bore be very smooth. Drilling can leave microscopic trace lines in the bore that EDM does not. EDM generally produces a non-marr finish inside the bore, which is preferred for some applications.

Shaped Holes

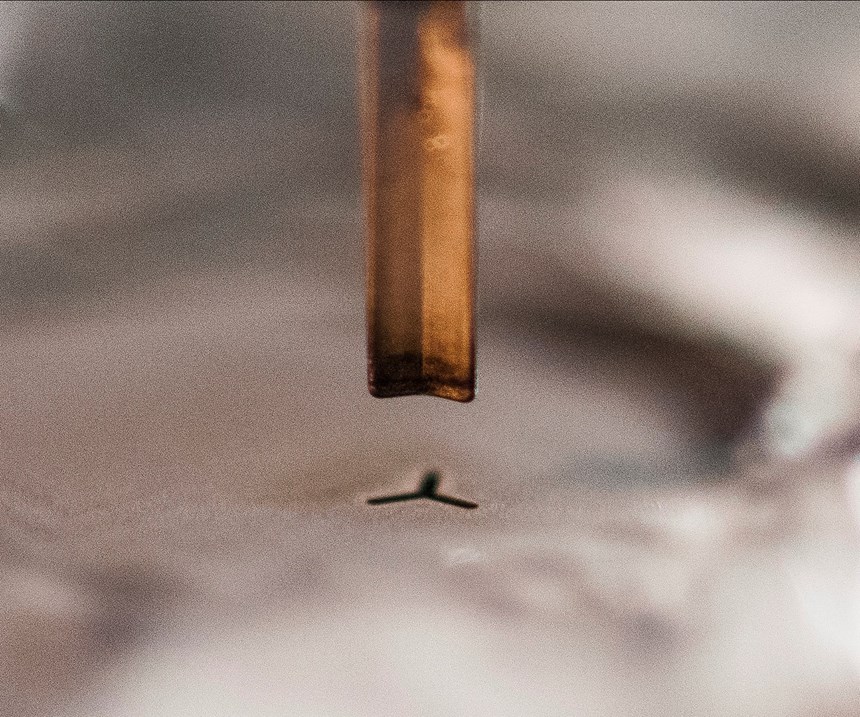

In addition to its micro-hole drilling expertise, National Jet specializes in cutting shaped holes. “These are produced using EDM,” Mr. Condor says. “We cut our own electrodes for these holes and burn them on our own ram machines made especially for these applications.”

One example is a tri-level, Y-shaped hole that functions as spinnerets for a die set used in the carpet industry. The bases are machined on the shop’s machining centers, then set up on the company’s die sinkers. Some of the dies have 300 of these holes in them.

Specifications for these electrodes are critical. One such Y-shaped hole, Mr. Condor explains, may be sized with the width of the legs being 0.006 inch, the length of the legs could be 0.020 inch and the depth might also be 0.020 inch.

The depth of the electrode is the most critical dimension for this shaped hole. Because the electrode is made slightly undersized, test cuts are made to bring the electrode to its optimum size for producing the tolerance and surface finish required.

The electrodes are redressed after each hole is cut. Once the machines are setup, they produce the die set holes automatically allowing for unmanned operation.

Collaboration

With its small-hole expertise firmly in place and having expanded its overall machining capabilities, National Jet increasingly is being asked to consult with its customers. It is being asked to suggest design changes by some customers that allow for more efficient manufacturing of the customer parts without sacrificing their functionality.

The company has built its business using its niche of high quality, specialty machining of small holes into the ability to offer a customer more than it thought it needed or thought it could get from a machine shop. In manufacturing, that is a good place to be, and this company’s family-owned culture is dedicated to keeping it that way.

National Jet Co. / 301-729-2300 / najet.com

.png;maxWidth=970;quality=90)