Subspindle Workholding Options

The advent of subspindle turning operations has impacted throughput for many shops. Understanding workholding options available for backworking can help a shop make better decisions when specifying how to hold parts for op. 20.

#basics

Finishing the part complete in one setup has long been the goal of most manufacturing companies both large and small. Not only does it usually mean faster throughput, but it also can mean a more accurate finished part.

For turning operations, this requires a machine with a subspindle to pick the part from the main spindle and finish the back side on the subspindle—the classic op. 10/op. 20 process. Perhaps the most critical, but often most overlooked, step in the process is selecting the proper workholding device. This becomes an important decision if a successful outcome is to be achieved.

Featured Content

Rick Schonher, workholding product manager at Hardinge Inc., says, “There are a number of issues to contend with when transferring a part from the main spindle to the subspindle. These issues need be dealt with up front to ensure a superior result. Whether the transfer uses the OD or the ID of the workpiece, part surface finish is often a vital component that has to be addressed. Finished surfaces require delicate handling, and the subspindle workholding device must not damage the part in any way.

“At this point,” he says, “scrapping a part can be very expensive depending on the material involved and the complexity of the component. Steel, cast iron or bronze are no longer the norm. Materials used today pose issues never experienced with these more common varieties. Many materials require unique workholding to eliminate the negative interaction. Accuracy is another important factor in the part transfer process. Total Indicator Reading (TIR) is tighter as machining is further and further away from the collet face, making this more difficult to achieve.”

Tom Sheehy, applications manager for machines at Hardinge, says, “Although bar work comprises the majority of subspindle operations, castings, near net shapes, powdered metal parts, forgings and others are also common. Chucking-type applications account for about 20 percent of the work done on subspindle-equipped machines and require different types of workholding devices. Often, the need to reduce part cost by removing the operator results in the machine being auto-loaded via a loading system or robotic automation.”

Hardinge offers many types of workholding products and solutions to facilitate the part transfer process for both bar and chucking operations. Emergency-style workholding devices, ones that are soft and able to be machined in place on the machine tool, are often the preferred method to be used, as they ensure excellent concentricity. These are especially useful for short-run production. For long-run production requirements, hardened and ground, as well as EDM hardened, are available. Here are some of the various types of spindle tooling available, as well as other machine-related features or options that may need to be considered for successful unattended operations and maximum efficiency.

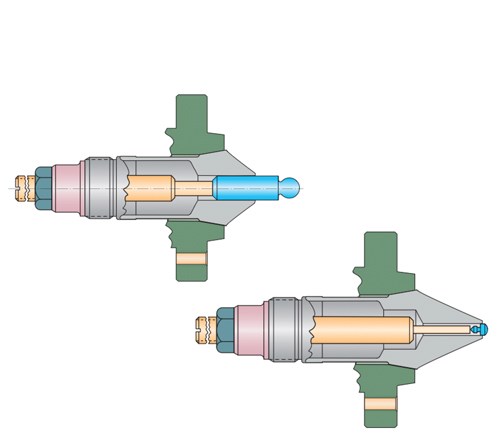

Extended nose collets: Extended nose collets are used to extend the part far enough to clear tooling interferences. Although they provide much-needed tool clearances, they can compromise grip strength and accuracy, especially when the part is short-length gripped and in front of the normal closing taper. Standard length collets are the better solution, if at all possible. Extended nose collets can compromise grip force and TIR as the part is gripped in front of the closing taper. There are pros and cons to both.

Slot width and corner breaks: In an effort to eliminate any markings on the workpiece surfaces, slot widths are narrower, and all sharp edges are broke and polished. This assists in eliminating or minimizing part surface finish damage on the gripping surface during the part transfer process.

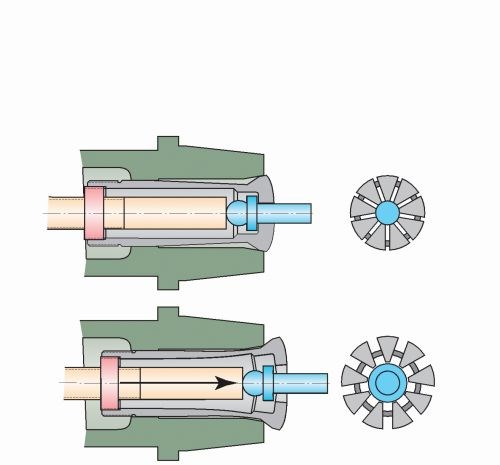

ID transfer: Parallel gripping provides the best holding power and rigidity for secondary machining. Blind holes and short gripping are obstacles, but these can be overcome. Small diameters become far more difficult, and there are definite limitations to how small the diameter can be. Large diameters can be difficult, but that relates more to the part size and weight than the workholding.

Dead length: Secondary or finish operations require length control. Stationary collets are predominantly used for subspindle applications. All draw-in collets have a diameter-to-length ratio when doing secondary operations. When using collets with a 10-degree head angle, the ratio is 1-to-3. For every 0.001-inch change in the chucking diameter, the part will either pull back 0.003 inch or stick out 0.003 inch from the setup part. This can mean a total length variation of 0.009 inch when the chucking diameter varies 0.003 inch. If the print calls for a length tolerance less than 0.002 inch, a standard collet cannot be used. This is where the dead-length collet fits in. If the stock diameter varies 0.003 inch, the finished part lengths will not vary more than a few ten thousandths (0.0002 inch to 0.0005 inch).

Grip force: Many machines have a limited adjustment to minimize closing pressure. Thin wall parts can be crushed or distorted with excessive grip force. Hardinge offers collets with a built-in force control that safely grips delicate or thin wall materials without crushing or distorting the workpiece while maintaining ID and OD concentricity.

Grip ranges for overgrip: Transfer diameters get smaller and smaller in many of the industries served by precision machined parts manufacturers. The part variation must be held tighter. Most collets do not offer parallel gripping and need to match part diameters. Hardinge offers over-the-shoulder gripping collets with multiple slots (or large slots) and double-angle design to allow the extra spread to clear a shoulder and grip on a smaller diameter beyond the feature. It is becoming much more prevalent to transfer over a larger diameter to grip a smaller diameter. Modifications to the collet, such as those listed here, are required to accommodate such applications:

Smaller pilot

Shortened closing taper

Steeper closing taper

Larger relief slots

Extra spread

Smaller body diameter

Specific back drill

Shorter gripping surface

Delivery: Lean initiatives, JIT and smaller lot sizes leave little room for scheduling. Customers need products sooner to meet these demands, all while expecting quality products at a reasonable price. Keep in mind that many of the workholding devices discussed are available in an emergency style, which will allow production to begin while waiting for delivery of a hardened and ground solution.

Eccentrics: The amount of eccentricity minimizes the part size being transferred to stay within the collet capacity. Spindle orientation is required to align the subspindle collet with the part. Spindle key and collet keyway dimensions need to be held tightly to achieve high accuracy alignment. Collet slotting may need to be modified to ensure even clamping forces.

Special shapes: Including extrusions and any non-round part such as hex, square or other shapes requires special consideration and may even need special software to facilitate the transfer process.

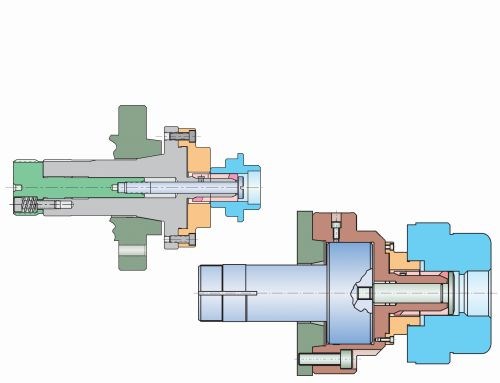

Quick change: This is predominantly achieved with an adapter. The adapter dimensions need to be evaluated closely to ensure there are no interferences. The collet style needs to match the largest part to be transferred to help keep the adapter small. Dead-length adapters are a must to hold lengths. TIR can be compromised by the number of moving parts within the adapter.

Part ejectors: High-production, long-running jobs are most effective by eliminating as much human intervention as possible. Part ejectors and part catchers/chutes aid this requirement.

Chip/coolant contamination: Sealed collets are recommended. High-pressure coolant is becoming more prevalent. However, it rapidly deteriorates certain types of slot seals.

Step chucks: Step chucks are an over-capacity collet that adapts to the spindle via an externally mounted closer. These are also available in a variety of configurations and depths for components that are too large for a standard collet. These work very well for near net shape forgings, castings, powder metal, and other chucking-type applications. These can be either emergency or hardened and ground styles. The major advantage of the step chuck system is that the part is encapsulated 360 degrees and is much closer to the spindle bearings versus a three-jaw chuck. By keeping the part closer to the spindle bearings, accuracy is increased in terms of roundness, concentricity and surface finish during the machining process.

At this point in the machining process, quite a number of operations may have already occurred and, as mentioned earlier, part damage at this stage can be expensive. In addition to the workholding technique or device used, specific machine options may also be required or considered to make for a smoother transfer with less risk of damage to the part or machine. Here, we are referring to the following options:

Through-spindle coolant and/or air blast: This minimizes contamination by cleaning out the workholding device prior to transfer to allow for a good part fit and to assist in ensuring the workholding device is free of chips. This results in reducing part runout or concentricity from the main spindle to subspindle operations and helps to ensure that the surface finish on the part chucked on the subspindle is not damaged.

Part present detection or other types of parts removal confirmation systems: This ensures that the part has

been completely ejected or removed from the subspindle prior to a new part being transferred. Damage to the part, or worse—damage to the machine tool—is possible if this process is not confirmed and controlled in some way. Sustainable machine downtime because of parts stacking can be minimized or eliminated.

Part removal systems: These should also be given a thorough analysis because there are a number of types available, and one may be more suitable than another depending on the part weight, surface finish, shape and any number of other characteristics. Some of the most common ones are conventional parts catchers, part conveyors, part gripping systems, pick-and-place systems and robotic devices.

It is best to consult your workholding and machine tool suppliers to review specific requirements for your shop’s operations. Often, they may have already seen a similar application and can offer a valuable insight on how to best approach the process for trouble-free production.

RELATED CONTENT

-

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.