Registration for next year’s International Manufacturing Technology Show is now open. (Image credit: AMT)

Were it not for COVID-19, IMTS 2024 would mark my 13th time attending the big show. But, 12 isn’t too shabby.

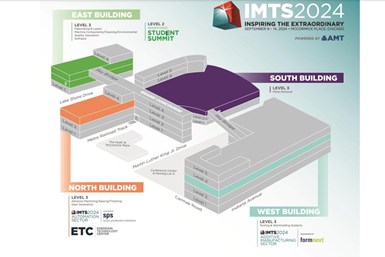

Registration for next year’s International Manufacturing Technology Show (IMTS), which runs September 9-14 at McCormick Place in Chicago, is now open at imts.com. According to AMT – The Association For Manufacturing Technology, which owns and produces IMTS, this upcoming show’s floor plan is a bit different, but is designed to reflect the strength of our manufacturing industry.

“To meet the needs of a robust manufacturing industry, IMTS 2024 will have even more exhibits that feature robotics, advanced motion systems, vision and imaging, data analytics, systems integration, software, artificial intelligence and connected technologies,” says Peter Eelman, AMT’s chief experience officer. “Every pressure on the manufacturing industry requires OEMs and job shops to implement technologies and processes that make them more efficient.”

Eelman notes that (as of June 2023) the monthly average of capacity utilization rates for durable goods manufacturing has remained above 75% for the last year. Manufacturing is also the beneficiary of the $1.2 trillion Infrastructure Investment and Jobs Act of 2021 and the $280 billion CHIPS and Science Act of August 2022. In addition, according to a recent U.S. Manufacturing Technology Orders Report published by AMT, new orders of manufacturing technology totaled $543.2 million in March 2023, one of the largest March totals since 2008.

“The focus on IMTS 2024 remains intense because we need a strong manufacturing industry,” Eelman maintains. “As a result, the IMTS exhibition space rebooking rate is as high as it has ever been, outpacing even IMTS 2018 or the dot-com boom years. Prominent exhibitors are expanding their footprint and companies that had paused their marketing plans have recommitted to IMTS 2024.” The show is on pace to exceed the 2022 show, which had 1.2 million square feet of exhibit space and more than 1,800 exhibiting companies.

So how is this reflected in terms of what’ll be new relative to the show floor? For one, IMTS 2024 will mark the premiere of the Automation Sector, accelerated by SPS – Smart Production Solutions, which will be in the North Building. AMT collaborated with the Mesago Messe Frankfurt Group, producers of SPS – Smart Production Solutions, to create the Automation Sector.

Locating the Automation Sector in the North Building provided space in the East Building for the Quality Assurance Sector and the Software Sector. The Fabricating and Laser Sector will also occupy the East Building. Plus, the Smartforce Student Summit will relocate to the second level of the East Building, reducing the distance between the student bus drop-off and pickup location, as well as the distance to the show floor.

Like Production Machining, events such as IMTS are an excellent way to discover new technology.

And as more businesses integrate additive manufacturing into their operations, Eelman believes they will want to plan for more time in the Additive Manufacturing Sector, said to be accelerated by Formnext, which is another new collaboration for AMT. “Additive manufacturing, automation and digital manufacturing are inherently intertwined, which is reflected in their growing prominence at IMTS 2024,” Eelman says. Co-located at IMTS, Formnext Forum is said to offer immersive learning experiences for attendees built around a robust conference schedule with an emphasis on sharing ideas and technology advancements in production 3D printing.

Like Production Machining, events such as IMTS are an excellent way to discover new technology that can possibly transform your machining operation. Registration to attend IMTS 2024 is now open. Visit imts.com to do so.

Read Next

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More