With Digital Sheet Metal Forming System, Desktop Metal Is Going Beyond Additive

The additive manufacturing technology provider is introducing Digital Sheet Forming (DSF), a solution that requires no tooling.

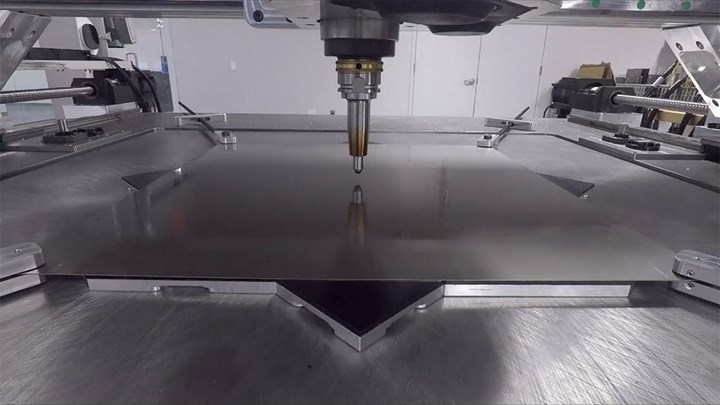

A ceramic tool forms the sheet in a proprietary build zone, eliminating the need for stamping tooling. Photo Credit: Desktop Metal

In addition to showcasing updates to its Shop System metal binder jet 3D printer, Desktop Metal is displaying hundreds of metal and polymer parts and the systems that printed them across its two booths in the West Building (Booths 433103 and 432212). But the additive manufacturing company is also launching an all-new digital manufacturing system not based on 3D printing.

On display for the first time at IMTS 2022, the Figur G15 is a commercial platform for shaping sheet metal on demand, directly from a digital file. According to the company, Figur’s patent-pending Digital Sheet Forming (DSF) technology eliminates the need for traditional stamping presses, tools and dies, for sheet metal forming that is accessible, flexible and cost-effective, even at low volumes. The platform will enable users to supply unique metal products and prototypes without long wait times.

The Figur G15 has an XY forming area of 1,450 × 1,000 mm and can process forms ranging to 400 mm in the Z direction. A software-driven ceramic tool on an XY gantry forms the sheet with as much as 2,000 lbs of force in a proprietary build zone. It can process a variety of metals and sheet thicknesses, including steel up to 2.0 mm thick and aluminum up to 2.5 mm.

RELATED CONTENT

-

5 High-Volume Machining Trends at IMTS 2022

Manufacturing businesses that machine parts in high volume are looking to new technology — hardware and software — to become more competitive.

-

Questions about Precision Machining? Ask Index

At this IMTS, Index Corp. is challenging show visitors to Ask Index key questions, the answers to which can help them ready their businesses for the next five years or more.

-

Swiss-Type Lathe Runs 2-Inch Parts Complete

This Swiss-type multitasking machine does all the crosswork and endwork milling, drilling and tapping complete, and even engraving and deburring, on one machine.

.jpg;width=70;height=70;mode=crop)