Causes of Part Length Variation on Screw Machine Parts

There are many different ways part length can vary when using a cut-off tool on multi-spindle automatic screw machines.

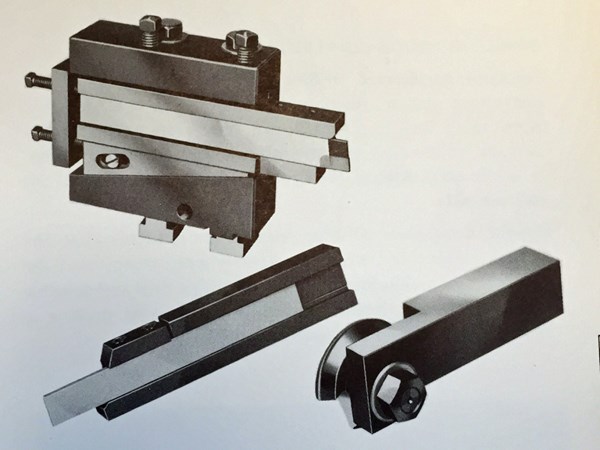

Photo Credit: "Acme Gridley Multiple Spindle Bar Machine Manual," First Edition 1961 page C11.

There are many different ways part length can vary when using a cut-off tool on multi- spindle automatic screw machines. Here are some of the major ones grouped into a rough classification by where the cause exists.

The cut-off tool itself:

- Tool is dull

- Tool is improperly ground (point angle too large)

- Tool loose/improperly inserted into holder

- Tool blade is too thin

- Cut-off tool is hitting while in high speed

- Cut-off tool being hit by die head or chasers

Cut-off toolholder:

- Toolholder itself is loose

- Toolholder is hitting work spindle

- Toolholder is hitting tool post

- Toolholder is warped or bent

- Toolholder is worn

The work spindle:

- Spindle has end play

- Spindle has worn bearings

- Spindle carrier has end play

- Index lock pin spring is broken

- Finger holder not adjusted properly

- Broken pins or fingers in finger holder

- Feed tubes bent or beat up

- Wrong stock feed cam—overfeeding stock will cause bounceback from stock stop resulting in short part

- Incorrect collet tension

The cross slide:

- Cross-slide play

- Cross-slide loose

- Cam is loose

- Cut-off cam is too large and causes too much feed

- Cam drum is loose

Other tools:

- Stock pushed back into collet by drill (dull drill pushing stock rather than cutting chip)

- Stock pushed back into collet by reamer

- Face-off tool is loose

- Face-off tool is dull

- Face-off toolholder is loose

- Die head pulling stock out of collet, making part long

Part length can occasionally go awry when using cut-off tools on automatic screw machines.

This post lists more than 30 reasons that I can think of. What did I miss?

Originally posted on PMPAspeakingofprecision.com blog.