Convenient Robot Training

This training consists of course modules that are self-paced, with videos, interactive simulations and practice exercises that enrich the virtual learning environment.

#workforcedevelopment

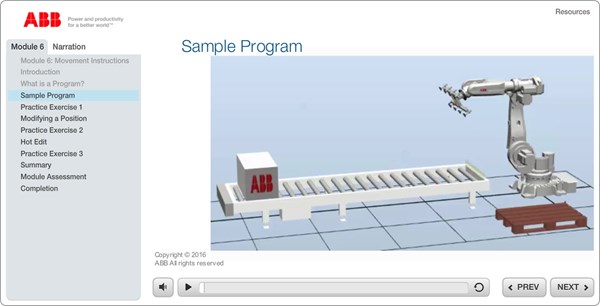

Learning the intricacies of robotic operation, kinematics and programming, usually means a trip to the manufacturer’s training facility or the training facility of one of its representatives. A new Web-based training program, developed by ABB Robotics, lets students and trainees receive the same quality and depth without the need to travel. The training is called IRC5 and consists of course modules that are self-paced, with videos, interactive simulations and practice exercises that enrich the virtual learning environment.

The goal of ABB’s first Web-based course is to offer a top level training option to students or employees who might not have time in their schedules to dedicate to an off-site course.

Students who successfully completing the course and its cumulative exam earn a certificate of completion along with continuing education units (CEUs). Increasingly, robots are being used in manufacturing, and having a well trained staff is in the best interest of every shop.

Click here to learn more about this convenient training program.

RELATED CONTENT

-

Choosing an Automatic Bar Feeder

The bar feeder is the most common form of automation for turning operations. Selecting the right one requires consideration of the applications for which it will be used.

-

Checklist for Lights-Out Manufacturing

Many shops of various sizes are trying to hop on the lights-out bandwagon. This article looks at some things to consider and check out before “hopping.”

-

Smart Workholding Device Measures and Monitors

Sensor and IIoT technology combine to enable these chucks and mandrels to automatically monitor workholding parameters and measure part features to ensure process stability.