Mitutoyo Celebrates Re-Opening of Cincinnati Solutions Center

The company held a ceremony at the remodeled M3 Solutions center, which was also expanded to make more space for its Custom Solutions division.

Mitutoyo celebrated the re-opening of its M3 Solutions center in the Cincinnati suburb of Mason, Ohio last week. According to President Matt Dye, the company renovated all nine of its solutions centers across the country with the goal of strengthening its commitment to its customers and suppliers. The newly remodeled Mason center houses between 15 and 18 employees.

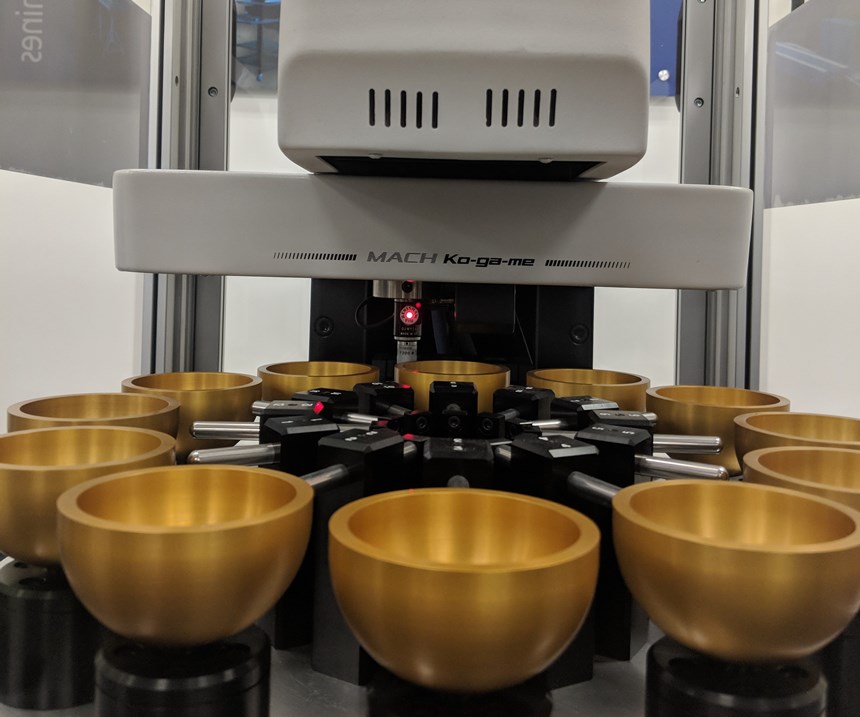

The center includes expanded space for the Mitutoyo’s Custom Solutions division. “We’re simplifying applications so our customers can better use their workforce,” Head of Custom Solutions Ken Myers says. These solutions can involve anything from customized fixturing to automation and in-line or near-line inspection systems that are designed to be used on the shop floor.

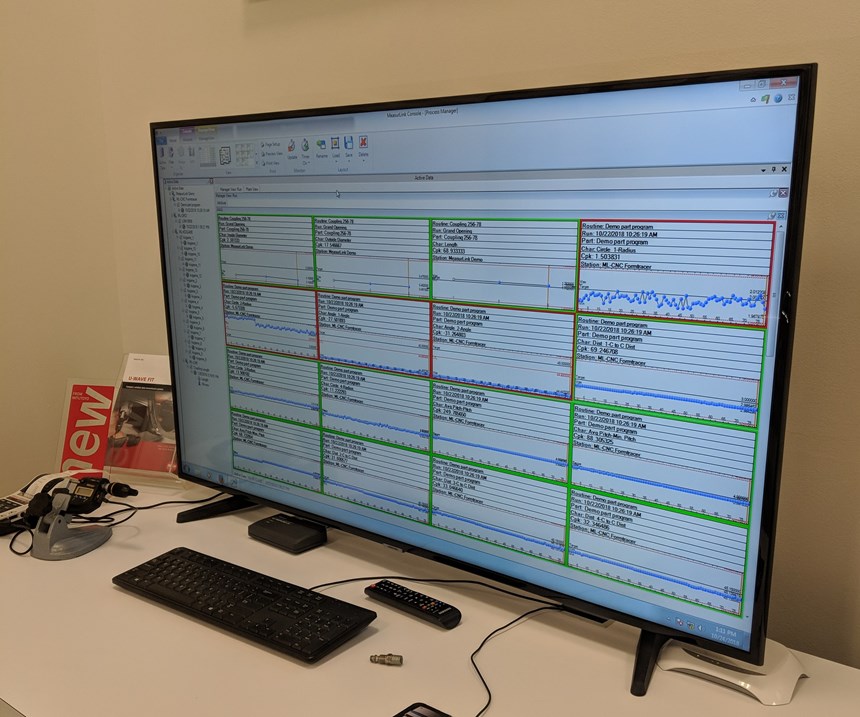

At the event, Mitutoyo was demonstrating many of its metrology and inspection products, including hand-held micrometers, coordinate measuring machines (CMMs), optical and vision measuring systems, and hardness testing machines. The company was also showcasing its MeasurLink statistical process control (SPC) software. The software collects data from a range of Mitutoyo inspection products, including its new U-Wave Fit attachment that wirelessly transmits data from a range of calipers and micrometers.

An interactive table that made its debut at the company’s IMTS booth last month was also on display at the event. Visitors could place smaller products or models of larger products onto the screen on the top of the table for more information about that product.

RELATED CONTENT

-

Sorting And Inspection...At What Cost?

Suppliers are feeling the heat to achieve zero defects PPM. Old methods are giving way to automated systems. Here’s a look at how lasers are leading the way.

-

Reducing Downtime With Tool Presetting

It’s an ongoing challenge. To remain competitive, shops must find new and more efficient ways to increase production. Often they look to new, faster and more precise machine tools as the answer. Sometimes experimentation with a variety of different tooling

-

How to Choose and Use Styli

The variety of probe applications on machine tools, CMMs, comparative gages and portable arms makes correct selection of styli usage essential for efficient, reliable and accurate measurement. Here are some key points that can be helpful in choosing the best measurement solution.