PartMaker Viewer for Data Sharing

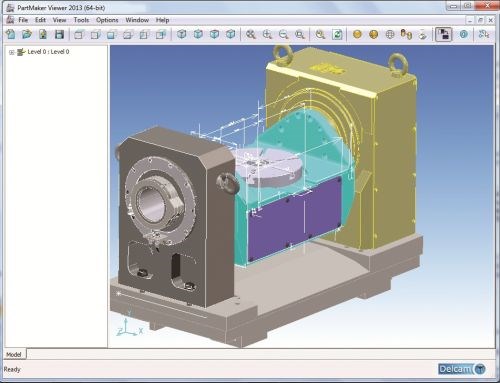

The free PartMaker Viewer utility allows users to view and share manufacturing and engineering data from 2D prints, 3D models and complete 3D assemblies.

Delcam’s PartMaker Division has launched a free utility called PartMaker Viewer. The software allows users to easily view and share manufacturing and engineering data from 2D prints, 3D models and even complete 3D assemblies. It can be downloaded here.

The viewer allows PartMaker users to collaborate with others in their organization as well as those outside of it who may not have access to PartMaker, free of cost. By simply exporting a file from PartMaker’s Simulation as an STL and bringing it into PartMaker Viewer, company management, shopfloor personnel, or even a shop’s customer or other external partners can see the work being done in PartMaker.

Viewer is a free utility offered by Delcam, not a timed evaluation that will expire. Contract manufacturers and job shops can encourage their customers to download the software to help in working more collaboratively.

“PartMaker Viewer is a great addition to the PartMaker CAD/CAM software suite,” says PartMaker Division President Hanan Fishman. “PartMaker provides a complete production engineering CADCAM solution from geometry creation, to engineering data repair and modification, to tool path creation, to machine simulation, to NC code generation.”

RELATED CONTENT

-

How to Get More Efficient Production from Swiss-Type and Multitasking Machines

SolidCAM for multi-axis Swiss type and multitasking machines provides a very efficient CAM programming process, generating optimal and safe Mill-Turn programs, with dramatically improved milling tool life.

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

Why Using Pirated Software is Riskier Than Ever

Machine shops and manufacturers that use pirated software risk losing much more – both directly and indirectly.