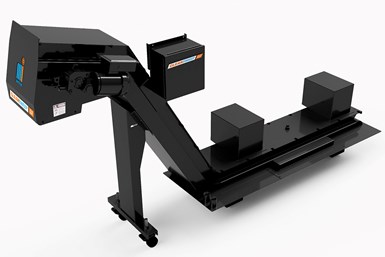

Chip Conveyor Provides Both Chip Handling, Coolant Filtration Functionality

PMTS 2023: The CleanSweep G2 is a self-cleaning conveyor designed to help operators eliminate the need for frequent coolant tank cleaning and maintenance.

#PMTS

Edited by

Mayfran International’s CleanSweep G2 expands on the functionality of the original CleanSweep-RM chip conveyor and aims to meet the changing needs of advanced machine tool applications. With the ability to handle higher coolant flows and a variety of fines, chips and turning types, the company says the CleanSweep G2 is a versatile solution that can help machine tool OEMs and operators reduce labor and material costs, leading to more efficient operations overall.

The CleanSweep G2 is a self-cleaning conveyor, helping operators eliminate the need for frequent coolant tank cleaning and maintenance. Under regular operating conditions, the CleanSweep G2 can help most customers reduce necessary coolant tank cleanouts to once per year. The results are increased machine uptime and extended coolant, pump and tooling life.

The conveyor also features a compact design to save floor space and minimize trip hazards. It has an inner handling system designed to reduce chip buildup in the conveyor. Mayfran also says the Clean Sweep G2 features effective coolant cleaning to a 150-micron nominal. The equipment comes with a heavy-duty belt with hardened components to provide long-term reliability.

Alongside the CleanSweep G2, Mayfran’s G2 “retrofit ready” hinged belts and conveyor retrofit kits are also available, enabling customers to upgrade their machines when they are ready.

RELATED CONTENT

-

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

-

Handling Parts In A Robotic Cell

Here’s a review of the workholding and workhandling challenges a shop faces as it moves a part through a robotic cell, from serving up the blanks to the transfer of the final workpiece to post processing and gaging. Productivity, Inc. takes the reader through a few of their cells that they've installed using Fanuc robots and a variety of other machine tool equipment.

-

LNS Turbo MH140 Chip Conveyor Filters Mixed Chips

The Turbo MH140 filtering chip conveyor is designed to prolong coolant life, reduce tool wear, protect coolant pumps from damage and reduce coolant tank maintenance.