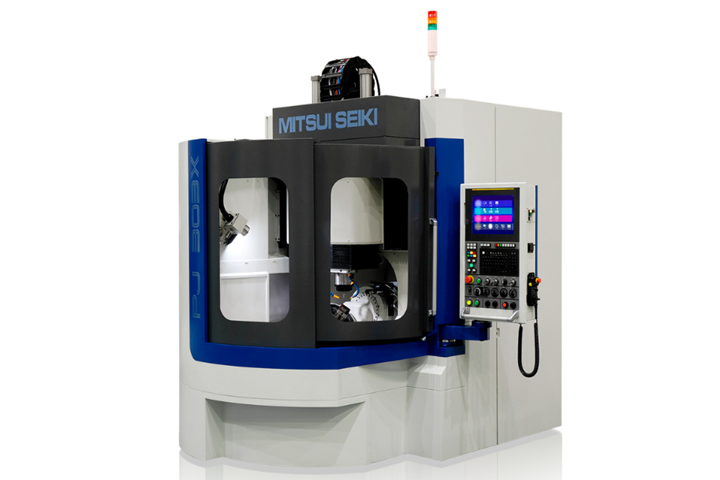

Five-Axis Machining Center Accommodates Small Workpieces

Mitsui Seiki’s compact PJ 303X machining center provides high precision, speed and versatility for critical parts such as lens molds, medical products and EDM electrodes.

Edited by Angela Osborne

Mitsui Seiki’s PJ 303X five-axis machining center is said to provide maximum precision and versatility in processing of workpieces up to 230 mm tall and 280 mm in diameter (9" x 11"), and 20 kg (44 lbs.) in weight. Typical applications cover an extensive range of critical parts such as lens molds, medical products, EDM electrodes and fuel cell components.

The PJ303X is designed to accurately machine smaller parts rather than large, critical components. Its X-, Y-, and Z-axis travels are 300 mm, 325 mm and 200 mm (11.8", 12.8", 7.9") respectively. A-axis rotation is +40 degrees to -100 degrees, and the C-axis rotates a full 360 degrees. High-speed linear motors move the X-, Y- and Z-axes, while the rotary axes employ direct-drive motors. Rapid traverse speed for the X-, Y-, and Z-axes is 20 m/min (66 ft/min).

A 50,000-rpm, HSK-E25 taper spindle is said to offer high-speed machining capability. An automatic toolchanger engineered to store up to 24 tools as large as 40 mm (1.57") in diameter and 100 mm (3.9”) in length provides tooling versatility.

To maximize precision, Mitsui Seiki says the attachment surfaces of the ways as well as other critical areas of the PJ 303X are hand-scraped. Advanced spindle thermal displacement technology is standard, including a symmetrical gantry column structure that accommodates thermal deformation fluctuations and a thermal compensation mechanism for the machine spindle/head. Operator-friendly features are said to further enhance precision.

RELATED CONTENT

-

Five-Axis Machining Center Performs Cutting Operations in a Single Setup

PMTS 2023: Haas’ UMC-350HD is a compact five-axis universal machining center Capable of performing 3+2 and five-axis machining simultaneously.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

High-Speed VMC Offers Intuitive Machining, Surfacing

In addition to inherent five-axis benefits, the Genmill VFM-2416 five-axis from Expand Machinery offers a range of features for optimal surface finishing.