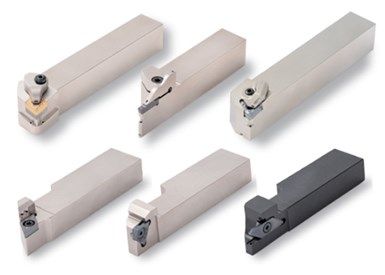

Kyocera JTC Holders Improve Chip Control, Wear Prevention

Appears in Print as: 'Jet Coolant-Through Holders Improve Chip Control, Wear Prevention'

Inch-size toolholders with high-pressure coolant delivery are designed to improve performance in turning, grooving, cut-off and threading applications.

Edited by Angela Osborne

Kyocera Precision Tools' jet coolant-through (JCT) toolholder series provides multiple high-pressure coolant streams at precise locations, giving manufacturers more chip control and wear prevention for small parts machining. Part of the JCT series tooling lineup includes inch-size holders to improve production with excellent performance in a variety of turning, grooving, cut-off and threading applications. According to the company, the toolholders feature easy connections with a high-pressure hose and joint. The internal coolant provides longer tool life and improved chip control.

RELATED CONTENT

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

.png;maxWidth=970;quality=90)