LK Metrology Gate is Flexible Inspection Monitoring, Analysis Portal

Portal provides remote access to information on the status and performance of all connected metrology devices.

Metrology Gate software

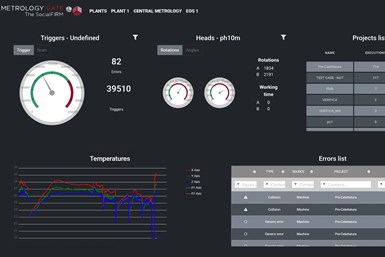

LK Metrology’s Metrology Gate portal is a flexible, web-based monitoring and analysis platform designed to help production departments monitor and control inspection activities around the clock. The portal provides remote access to information on the status and performance of all connected metrology devices.

Available information includes measurement results and a summary of errors; a record of program changes; uptime of the coordinate measuring machines (CMMs); and overall equipment effectiveness (OEE). Historical logs assist troubleshooting and warn when routine maintenance is due — not only of the inspection machines but also of the machine tools or other equipment on which the components are being made.

Comprehensive daily reports include total output per shift and the number of parts measured, sudden changes in process averages, and comparisons between different machines producing the components. Graphical CAD reports, statistical process control (SPC) analyses with Cp and Cpk results, and environmental logs (including operating temperature) are generated and communicated, alongside charts to aid interpretation and understanding.

In the case of critical dimensional discrepancies or hardware failure, the software immediately shares the information with users by sending alerts via email, SMS, WeChat or WhatsApp. Metrology jobs can be stopped and reset if performance is inadequate, thereby maximizing yield and minimizing scrap. A dashboard containing details of the errors may be viewed on a web page.

The data is instantly accessible over the internet and globally in real time on an office PC or using an app on handheld devices. Using this data, the platform can cut costs and increase savings. Also, quality control data is acquired automatically and objectively, thus helping to ensure its accuracy. Reports can be produced automatically and be easily tailored to suit what the user needs to see. A hierarchical permissions structure can be built into the platform so that personnel have access only to information relevant to their seniority and requirements.

Related Content

-

Precision Machining Technology Review: August 2025

Production Machining’s August 2025 technology showcase includes some of the latest technology from Big Daishowa, Greenleaf, The L.S. Starrett Co., Schwanog, Supertec and SMW Autoblok.

-

In-Machine Probing Possibilities for VTLs

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

-

The Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.