Open Mind hyperMill CAD/CAM 2022 Offers Enhanced Functionality

Appears in Print as: 'CAD/CAM Software Offers Enhanced Functionality'

The latest enhancements are designed to give users increased convenience and faster programming tools for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

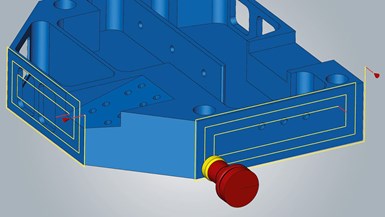

Fully automated hyperMill 3D plane machining searches for suitable, high-performance path layouts. Photo Credit: Open Mind Technologies

Open Mind Technologies’ hyperMill 2022.1 CAD/CAM software suite is said to offer enhanced features for more powerful NC programming in applications ranging from 2.5D to 5-axis. The software is designed to give users increased convenience and faster programming tools for toolpath optimization, tool management, virtual machining, additive manufacturing, EDM, mill-turn and more.

Highlights in hyperMill 2022.1 include a break-edge function for contour milling, combined pocket milling together with a finish path enabling cutter compensation and increased efficiency for 3D plane machining. The automated 3D plane machining strategy is said to improve machining quality by searching for suitable path layouts according to parameters such as when adaptive pockets are present.

For improved tool data reliability and time savings, tool data (such as length, radius, corner radius, and tool number and name) can be transferred directly from hyperMill to a Heidenhain TNC640 control using the connected machining module. It is also possible to import calibrated tools from a tool management system into the software to create programs and then transfer the tool list or individual tool data to the machine.

New extensions to the hyperMill mill-turn capability include more streamlined programming and simulation processing and management for machines with main- and counter-spindle configurations.

RELATED CONTENT

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

Automatically Optimize Your CNC Machining Feed Rates

New feed-rate-optimization technology can enable CAM programmers to reduce cycle times and increase tool life for milling and turning operations.

-

Swiss Shop Chooses CAM Over Hand Programming

This shop’s manual (by hand) CNC programming was slowing it down until it discovered a CAM software for Swiss-type lathes.