Productive Robotics’ OB-7 Offers Longer Reach

Appears in Print as: 'Teachable Robot Offers Longer Reach'

OB7-Stretch can tend multiple machines at one time when the robot needs to reach more than one machine and when the robot needs to reach deeply into a machine.

Edited by Angela Osborne

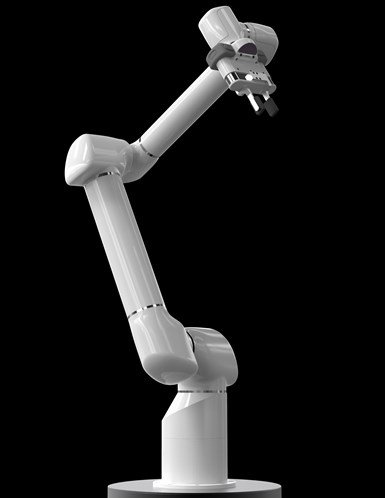

Productive Robotics’ OB7-Stretch is the fourth model of its next-generation teachable collaborative robots (cobots). According to the company, this cobot is simple, affordable and has a longer reach to handle parts and machines with longer distances. OB7-Stretch is similar to the standard OB7 5-kg model, but has a longer reach of 1.25 m and a slightly lower payload of 4 kg.

The company says its 7-axis cobot is well-suited for applications that require a longer reach for picking up a part or reaching deeper into machines, such applications in plastics molding, packaging and palletizing. In CNC machine tending, OB7-Stretch can tend multiple machines at one time when the robot needs to reach more than one machine.

OB7 is said to offer flexibility thanks to its seventh axis. Like a human arm, seven joints give OB7 the flexibility and dexterity to reach around objects or obstacles where others can’t. Unlike a human arm, each of OB7’s joints can rotate 360 degrees in both directions, which allows the cobot to work in more confined workspaces and areas that a six-axis robot can’t reach. While Productive Robotics has two larger models with longer reaches (OB7-Max 12 and OB7-Max 8), the company designed the OB7-Stretch to provide a cost-effective alternative to higher-payload and reach robots.

The company’s three other cobot models include standard OB7 (5kg payload and 1 m reach), OB7-Max 12 (12 kg and 1.3 m reach) and OB7-Max 8 (8kg payload and 1.7 m reach). Each cobot is built with seven-axis capabilities and a “no programming,” simple, teaching platform. The user simply shows OB7 how to do the job and OB7 learns — providing customers with ease of use.

RELATED CONTENT

-

10 Smart Steps to Take Toward Recovery

With many manufacturers facing challenges in light of the novel coronavirus pandemic, these 10 steps can help position manufacturers to find success.

-

Job Shop Automation: Fast, Simple and Agile

When done right, automation can provide important benefits. Here’s a look at automation options to suit the varying needs of typical job shops.

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.