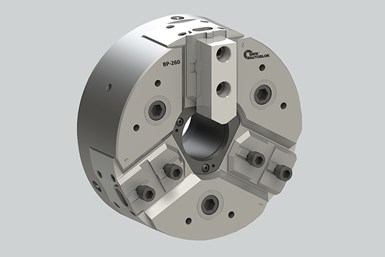

SMW BP Chuck Made for Harsh Machining Environments

Appears in Print as: 'Chuck Made for Harsh Machining Environments'

The BP features a large through-hole that enables flexibility for virtually any application where a standard chuck is used.

Edited by Angela Osborne

The BP is designed to only require maintenance intervals every 2,000 hours, not every shift.

SMW Autoblok’s BP chuck is a standard, fully sealed power chuck designed with large a through-hole for maximum precision and durability. The company says the chuck is well suited for CNC lathe applications thanks to a large through-hole that enables flexibility for virtually any application where a standard chuck is used, including OD and ID clamping, bar stock clamping and shaft clamping. Users can also convert the BP to a collet chuck using collet pads for small diameter parts.

The BP is said to maintain high productivity even in harsh environments, including dry machining, abrasive powders, high pressure or corrosive coolants and more. Constant grease lubrication provides clamping force consistency and reduced wear to greatly reduce downtime and loss of productivity, the company says. The BP also eliminates daily maintenance intervals, only requiring maintenance checks every 2,000 hours.

The chuck is fully Proofline-sealed from outside contaminants, enabling the BP to maintain a consistent grip force for repeatability at high speed, versus non-sealed chucks which can lose more than 50% grip force if not maintained properly. Other advantages include a case-hardened body and internal parts for high resistance and longer life.

Available in 210, 260, and 320 mm, BP series chucks accept all industry top jaws. The BP-D utilizes master jaws with inch serration, while the BP-M operates with metric serration (suitable for Japanese jaws). The American standard tongue and groove master jaws, are available on the BP-C.

[DK1]Brand name

RELATED CONTENT

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.