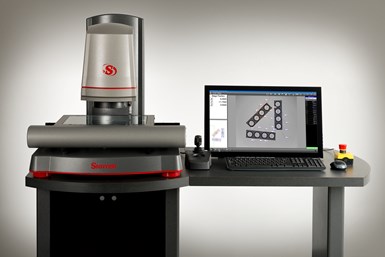

Starrett's Multisensor Vision System Provides Large Field of View

Appears in Print as: 'Multisensor Vision System Provides Large Field of View '

IMTS 2022: The AVR-FOV 0.14X multisensor vision system is designed to provide accurate, efficient measurements fora wide range of parts.

#imts

Edited by Angela Osborne

Photo Credit: The L.S. Starrett Co.

The L.S. Starrett Co. has enhanced its AVR300 Multisensor Vision System with a large 2.36" (60 mm) FOV-dedicated 0.14 times telecentric lens for micron-level resolution and accurate field-of-view (FOV) measurements.

The company says more of the part can be viewed in every image on the new AVR-FOV 0.14X system, offering greater efficiency and accuracy. Due to “superimage” technology (which enables multiple images to be stitched together to form one larger image) together with the system’s touch probe technology, the AVR-FOV 0.14X is said to accurately inspect a wide range of features on large or complex parts, as well as on multiple small parts.

The AVR-FOV 0.14X automated part programs is said to deliver accurate results to the micron level in a matter of seconds with “Go/No-Go” tolerance zones, and data is provided in one easy-to-interpret report. These features are said to enable metrology users in manufacturing facilities or QC labs to produce accurate, fast and repeatable results.

Equipped with the M3 software package from MetLogix, a traditional mouse as well as a touchscreen monitor are said to make user interaction easy and intuitive. Auto part recognition enables creating a part measurement program that comprises the desired features of a part for inspection, which can automatically be saved in the system or to a network, the company says.

Programmable light output options can be built into the program as defined steps, including being called up as the part recognition program initiates. Once the program is created, placing that part within the camera’s field-of-view enables the saved program to initiate and run the inspection. A Renishaw Touch Probe can also be utilized for quick acquisition of discreet points along a part’s profile as well as Z-axis measurements.

The AVR-FOV 0.14X has an X-Y-Z travel of 12" x 8" x 8" (300mm x 200mm x 200mm). The Starrett AVR-FOV 0.14X Multi-Sensor Vision System is made in the U.S.A.

RELATED CONTENT

-

How to Choose and Use Styli

The variety of probe applications on machine tools, CMMs, comparative gages and portable arms makes correct selection of styli usage essential for efficient, reliable and accurate measurement. Here are some key points that can be helpful in choosing the best measurement solution.

-

Precision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.

-

Precision Laser Measuring in a Grinding Machine

This laser measurement technology inside a grinding machine presents numerous advantages including noncontact, multiple-diameter measurement with no mechanical setup required.

.png;maxWidth=970;quality=90)