Vardex Threading Toolholders Offer Two Coolant Ports

Appears in Print as: 'Threading Toolholders Offer Two Coolant Ports'

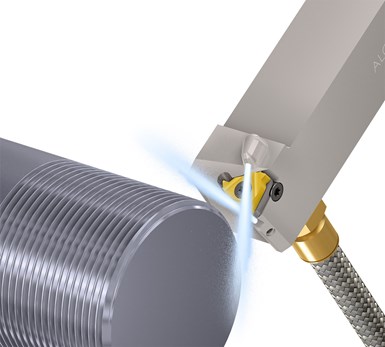

Vardex external thread turning toolholders have two high-pressure coolant outlets for greater precision and longer tool life.

Edited by Angela Osborne

Vargus USA’s ALCN line of external thread turning toolholders feature two precise, high-pressure coolant outlets designed to cool the top and bottom of the insert for longer tool life, and are specially manufactured for high-pressure coolant (up to 70 Bar). According to the company, when used with a quality coolant, the cutting-edge temperature is dramatically reduced, thereby increasing tool life. Also, the through-coolant capability improves chip evacuation for better chip control and flow, and enhanced productivity.

The new toolholders also feature three coolant inlets, suitable for some of the most popular machines on the market, including a bottom inlet designed for standard screw connection;

a bottom inlet specially designed for VDI Holder according DIN 69880/ISO 10889; and a back inlet designed for standard screw connection. The toolholders are available for Vardex standard lay-down insert sizes: 3/8", 1/2" and 5/8", and are offered in metric and inch shanks. Additionally, the new range also offers left hand toolholders as standard. All new toolholders are nickel-coated for better wear resistance and anti-corrosion protection. The new toolholders are integrated into the Vargus Genius software for tool selection and accessing suggested cutting data.

RELATED CONTENT

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

Selecting the Right Milling Tool for Any Machining Task

High-performance milling cutters combine high cutting data with long tool life and efficiency, but certain factors must be considered when selecting tools for different machining tasks.