A Cool Way To Cool

With increasing regulations on handling and use of metalworking fluids, the industry needs to look at other options to help resolve the contradictions between the need for cooling lubrication and the requirements for cleaner, safer technology.

While technological advancements continue to be the norm throughout most of the industry, from machine tools, to cutting tools, to controls to cutting fluids, not much has really changed in how cooling lubrication is applied. The typical practice of flooding the work area with fluid, though, needs to be reexamined. In many operations, this process is wasteful and may even interfere with the performance of advanced machining processes, materials and equipment.

Direct costs of flooded cutting fluids often exceed 10 percent of the total cost of a manufactured workpiece. Further indirect costs such as handling/disposal expenses and employee protection also must be considered. With increasing regulations on handling and use of metalworking fluids, the industry needs to look at other options to help resolve the contradictions between the need for cooling lubrication and the requirements for cleaner, safer technology.

Because of the impact of environmental and operational cost pressures, alternatives to current practices are gaining momentum. The minimum quantity lubrication (MQL) approach uses a small amount of oil that is entrained as microscopic droplets in an air stream and delivered as a coherent dry (air only), near-dry and wet machining spray. For many machining processes, MQL shows potential, but issues related to cutting zone penetration, tool adaptation and cooling capacity have slowed its acceptance.

For applications demanding cooling rather than lubricity, cryogenic techniques such as liquid nitrogen or carbon dioxide sprays can be considered, but these techniques tend to be restricted to high-speed cuts, specialized tools and harder materials and involve extra setup and operational complexities.

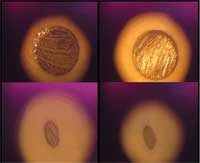

The ideal cooling lubrication technology would be applicable with a variety of machine tools, methods and practices, using existing fluids, in a simple, clean and adaptive approach. One such method, called advanced minimum quantity cooling lubrication (MQCL), employs simple but powerful physics and engineering principles in an effort to provide superior penetration, cooling, cleaning and lubrication of the cutting zone. This process combines the most beneficial physicochemical actions of alternative cooling lubrication and spray technologies into a single process.

The advanced MQCL system combines a source of propellant gas, lubrication additives and solid and/or gaseous CO2 in various concentrations to form an infinitely adjustable cooling lubricant spray. With a Coanda-coaxial injector and spray applicator, a passive electrostatic charging mechanism is used to enhance droplet uniformity, spray force and machined surface deposition. An active electrostatic charging system can also be used to provide combination spray charging capability.

To apply the Coanda effect for both additive injection and spray flow pattern control, the system sends a mixture of propellant gas and additive along the Coanda profile as a thin film powered by both propellant gas and atmospheric pressure shear stresses. The film sheds into and mixes with the lower-pressure coaxial CO2 stream. The Coanda effect creates an atmospheric pressure tunnel that extends for a relatively long distance from the nozzle tip towards the machining operation. This tunnel confines and shields the charged cooling lubrication spray as it moves from the nozzle to the cutting zone.

The combination of renewable bio-based feedstocks such as CO2 and vegetable lubricants used in advanced MQCL provides an environmentally sound and worker-friendly alternative to petroleum-based cooling lubricants. The minimum quantities applied help to reduce costs associated with treatment, environmental compliance, disposal and other operational requirements. These fluids also perform favorably when compared to petroleum-based fluids for machining steel and aluminum.

Advanced MQCL helps control machining heat by using both a physical and chemical effect. In the chemical effect, frictional heat generated at the cutting edge is eliminated through the delivery of reactive lubricants, including CO2. The physical effect removes the majority of the machining heat produced by the deformation of the material using adjustable spray compositions containing microscopic particles of solid CO2. These particles impact hot surfaces at high velocity and remove the heat through a phase change. These combined methods effectively control heat generation, not allowing heat to accumulate in the tool or workpiece.

Advanced MQCL technology can help businesses reduce costs and environmental pollution without compromising the selectivity, control and performance that they now enjoy with current metalworking fluid technology. These methods address the shortcomings of the cutting fluid alternatives while capturing all of their inherent benefits. Advanced MQCL is applicable to metalworking and machining operations such as turning, milling, facing, threading, boring, grooving, grinding, dicing and polishing, particularly in high-speed operations.

This enabling technology can be implemented alongside many older and newer machining alternatives, including machinery, materials, methods, processes, cutting tools and fluids, augmenting a successful conversion to a clean and lean metalworking operation.

Related Content

Big Daishowa Angle Head Enhances Productivity, Chip Removal

Big Daishowa Inc. introduces the TAG90 center-through-coolant angle head, designed for improved cooling efficiency and accuracy in complex machining applications.

Read MoreJorgensen Coolant Filtration Systems Boost Chip Evacuation

Jorgensen Conveyor and Filtration Solutions’ Flexforce high-pressure coolant system, Ecofilter 80 conveyor and updated Magnetic Conveyor are designed to reduce downtime.

Read MoreMarubeni Citizen-Cincom Accessories Provide Faster Cycle Times

IMTS 2024: Marubeni Citizen-Cincom is showcasing a range of machining accessories designed to work intuitively with Citizen machines.

Read MoreTJ Davies Coolant Tubes Enhance Toolholder Performance

TJ Davies Co. Inc.’s line of coolant tubes and wrenches designed for HSK toolholders are available in sizes from HSK-25 to HSK-125.

Read MoreRead Next

How To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Co. is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreFinding the Right Tools for a Turning Shop

Xcelicut is a startup shop that has grown thanks to the right machines, cutting tools, grants and other resources.

Read More