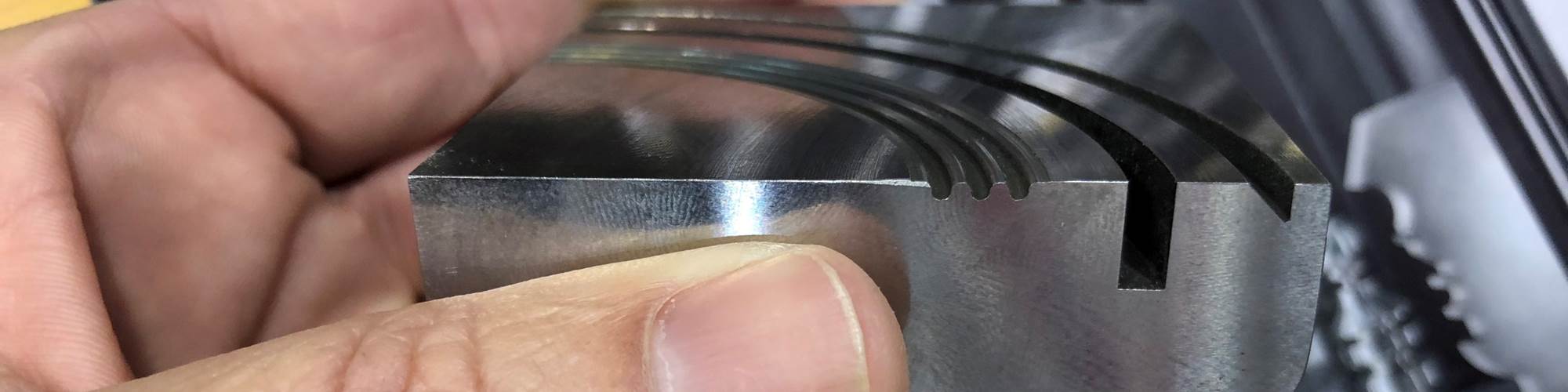

As an alternative to end mills, this trepanning tool can produce both symmetrical and asymmetrical face grooves, too, and perform fly cutting. Groove diameters are concentric to spindle rotation and not subject to error due to table movement.

Photo Credit: Kaiser Tool Co.Traditionally, machine shops had two options to machine circular grooves in the face of a part. One is to spin a part in a turning center and feed in a static face-grooving tool. The other is to use a machine tool to circle-interpolate using an end mill. Shops typically go with the latter option when the part cannot be chucked in a turning center, has a geometry that includes bosses or features impeding tool access, or would create an out-of-balance condition when spun. However, tool breakage and long cycle times can be an issue, especially when using small-diameter end mills. Plus, those tools create only symmetrical groove profiles.

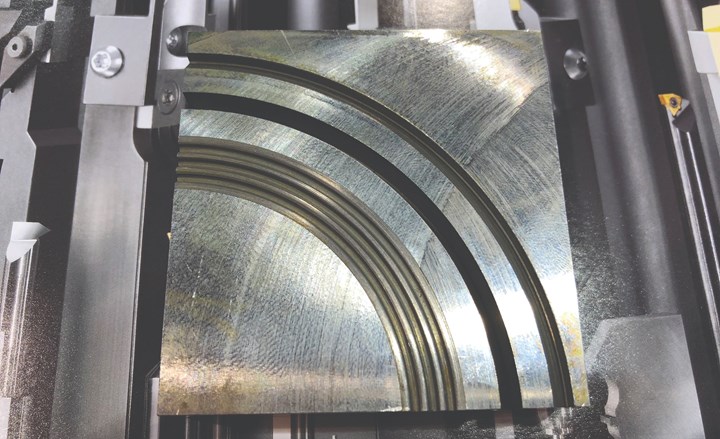

Thinbit/Kaiser Tool Co. has developed a trepanning-type tool based on the static, lathe, face-grooving inserts it has offered for many years to enable single-point cutting of grooves on a machining center. Called Mill A Groove, this line of tools installs in a user’s boring head to enable a range of groove diameters — with a symmetrical profile or not — to be created.

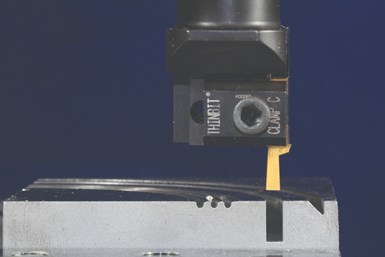

“We’ve noticed an increasing number of applications in which end mills are used on machining centers to create face grooves primarily for seals or where parts mate together in an assembly,” says company COO Ken King. “With Mill a Groove, we’re using our lathe face-grooving inserts, which range in widths from 0.004 to 0.150 inch, in a newly designed toolholder to enable trepanning operations on a milling machine.”

Custom insert profiles can be created based on application requirements.

King says, compared to end milling, this tool offers advantages such as better groove concentricity and surface finish. It can also eliminate the need to take a milled part to a lathe for a secondary face-grooving operation. In addition, tests have shown that the tool can produce grooves as much as 90% faster than machining with an end mill. In test comparison cuts, the Mill A Groove produced a 0.125-inch-wide face groove in steel in 18 seconds versus three minutes with an end mill. Cut data for the Mill A Groove is determined by simply converting the speeds and feeds used in a lathe face-grooving operation to a single-point milling operation.

Cut data is determined by simply converting the speeds and feeds used in a lathe face-grooving operation to single-point milling.

The Mill A Groove can also be used to perform face milling as a single-point, fly-cutting operation. This can be advantageous for applications in which minimal machining witness marks are desirable. For example, using a 1-inch end mill to face a surface wider than that will leave behind multiple 1-inch rows of witness marks. Setting up a Mill A Groove tool in a boring head with a diameter bigger than the part width and performing a fly-milling operation leaves a more uniform surface finish.

Shanks are available in various sizes to accommodate a range of boring head models.

Mill A Groove shanks are available in seven sizes — 0.5, 0.625, 0.75 and 1 inch and 16, 20 and 25 mm — to accommodate a range of boring head models. Inserts for the Mill A Groove system are available in widths from 0.004" to 0.150" in 0.001" increments. Major diameters include 0.300", 0.750", 1.250" and 3". Depths of cut of 2.5 to 3 times groove width are possible.

Inserts are available in submicron grain carbide grades for ferrous and nonferrous materials and in HSS for composites and plastics. Inserts can be coated with TiN, TiCN, TiAIN or diamond film coatings. Kaiser Tool also offers PCD and CBN tipping options for improved performance in hard or abrasive materials. Custom insert profiles can be created based on application requirements.

Related Content

Cutting Tool Considerations for Hydraulic Port Machining

Indexable insert cutting tools can boost the efficiency of port machining processes by creating multiple features in a single operation.

Read MoreThe Promise of Additive Manufacturing for Paul Horn GmbH

Additive manufacturing offers various benefits for cutting tool manufacturers such as reduced tool weight and the creation of complex internal coolant channels that cannot be produced via traditional CNC machining methods. Here is how it currently plays out at one such German company.

Read MoreTurning Tips for Tough Materials

Consider these six ideas that can help you overcome the turning challenges posed by exotic materials.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreRead Next

When a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreAngled Toolholders Position Inserts for Various Turning Operations

The angled square toolholders position the insert at 30-, 45- or 60-degree angles for reliefs, undercuts, angled OD and face grooves.

Read MoreLow Frequency Vibration Increases Job Shop’s Productivity

With the ability to machine difficult materials more efficiently while improving surface finish, this job shop is reaping the benefits of its Swiss-type lathes that incorporate low frequency vibration.

Read More