CAM Selection Criteria For Your Swiss-type

Programming complex Swiss-type lathes is simplified with a good CAM purchase. Here are some questions you should ask your vendor.

"Dropping a part complete" has become a mantra for both job shops and OEMs alike in today's manufacturing environment. As a result, multi-axis CNC Swiss-type lathes and turn-mill centers have been rapidly growing in both popularity as well as complexity. The great draw of these machines is their ability to slash cycle times by combining milling and turning operations in a single setup as well as allowing multiple operations to be performed simultaneously by different tools on separate spindles.

The complexity of these machines—they have anywhere from three to as many as 14 (gasp!) programmable axes—has increased the CNC programming burden carried by shopfloor personnel. Fortunately computer aided manufacturing (CAM) technology, which allows manufacturing personnel to develop NC programs "off-line" at a desktop PC, has recognized the situation in production machining. Historically the domain of the CNC milling world, PC-based CAM has finally evolved to point where it can help shops make the leap to programming multi-axis Swiss-type lathes and turn-mill centers in a cost-effective manner.

Featured Content

Industry Situation

If you are like any number of other precision manufacturers, whether you are a job shop or involved in production for an OEM, you have probably noticed these trends influencing your business over the past few years:

- The number of parts per order or batch has dropped of considerably with the advent of "Just in Time" inventory and other modern manufacturing approaches.

- Skilled machining and NC programming talent is becoming more expensive and more difficult to find.

- Part tolerances required by customers are becoming more and more stringent.

Many manufacturers have responded to these developments by upgrading their machine tool hardware to those that hold higher tolerances, have shorter setup times and require less operator intervention by allowing a part to be machined complete in a single setup, for example dropping a part complete. For shops that have relied on cam driven "screw" machines, this has meant embracing CNC. For shops that are already using CNC, this has meant looking for equipment that eliminates as many secondary machining operations as possible. "Secondary Ops" increase cycle times, decrease the likelihood of achieving repeatable tolerances from part to part and are highly labor intensive, hence the rise in popularity of multi-axis sliding-headstock CNC Swiss-type lathes and fixed-headstock turn-mill centers.

Also driving the growth of more complex CNC Swiss-type lathes and turn-mill centers are our growth industries. Fields such medical, electronics, consumer and telecommunications all require parts ideal for manufacture on such machines.

The result: machines are becoming more complex, requiring more advanced NC programming techniques, while the shopfloor personnel capable of processing parts on such machines are becoming more scarce.

CAD/CAM To The Rescue

The ever-increasing pressure on decreasing part-processing time has forced manufacturers to automate with technology wherever possible. Such automation can be achieved in NC program development and optimization with the right CAD/CAM programming system. The goal of any CAM system is to get the NC programmer from a part print to the completed NC program ready to run on the machine. What differentiates one system from another for your shop is how quickly and intuitively it lets the user do so for your application.

Performing NC programming via a CAM system has a number of benefits. A few of the major benefits for production manufacturers are addressed below:

1. Faster Program Creation: The first and most important of these benefits is that parts can be programmed faster using a CAM system versus doing so manually. This can be achieved because cutter movements or tool paths can be developed via a visual user interface by just entering machining parameters and letting the software perform the necessary trigonometric calculations and output the requisite NC program for a particular machine tool. For most production shops, adopting a CAM system means getting away from a manual or hand programming situation—where NC programs are actually written by a programmer and sent to the machine tool or developed right at the control. In effect, CAM systems automate the programming process.

2. More Optimal Resource Utilization: Programming your machine tools—especially the most complex and expensive ones—with a CAM system provides a big opportunity for cost savings as well. Instead of using a piece of CNC equipment that costs $150,000 or more to develop and prove out a program, you can do so on a desktop PC in the shop.

In addition, the right CAM system will not only speed programming but will also allow programmers to optimize programs at their desktop PC. Often, when programming manually, programmers have spent so much time just writing the program, they do not devote proper time to optimizing it—making sure the capabilities of the machine tool are correctly utilized. In the case of a CNC Swiss-type lathe or a turn-mill, this can entail making sure operations on both spindles are as closely "balanced" as possible, meaning machine cycle times running on either the main or subspindle are as close to equal as possible. The closer cycle times on the main and subspindles are to one another, the closer cycle time is to being divided in two.

In this vein, as a byproduct of the programming process, a CAM system will typically produce a time study for a particular part that can in turn be used to quote the cost of a job or help the shop decide on which CNC equipment to route a particular job.

3. Improved Organization of the Manufacturing Process: Off-line programming with a CAM system tends to be a better organization of the manufacturing process because it lets the programmer think about the process, from part design, to tooling requirements to cutter paths all in advance of putting the program on the machine. Thinking through the process systematically allows the programmer to make sure all the resources are available to properly manufacture the part. Programming at the machine control can be sidetracked and held up by such common occurrences as forgetting a tool or an issue of similar nature. When the machine isn't cutting, it's not making money.

4. Wider Sharing and Storage of Expertise: In recent years, the advent of knowledge-based machining (KBM) has made CAM systems more than just a means for quicker programming, but also a suite of shop management tools. KBM stores the unique knowledge of the most expert machinists in the shop about such issues as tooling, feeds and speeds and repetitive processes being executed from part to part and allows this information to be reapplied automatically to future parts. Not only does this speed up programming, but it also allows less experienced personnel to benefit from the expertise of the most knowledgeable machinists in the shop.

The storage of information provided by a knowledge-based system can help unify programming across the shop where a number of individuals are programming or in shops where personnel turnover in NC programming may be an issue. In addition, KBM can help speed up training of new personnel by allowing them to tap into databases of company knowledge right away instead of having to remember instructions given to them over a longer period of time.

5. Higher Precision Parts: CAM systems also allow manufacturers to produce higher precision parts. This can be achieved by programming directly onto the geometry of a part print, where the geometry has been created by the programmer or brought in from an outside engineering system used to create the part drawing by a customer or in the design department. In doing so, tool geometries and optimal feeds and speeds are taken into account automatically to achieve the desired results in terms of such items as surface finish and cutter compensation.

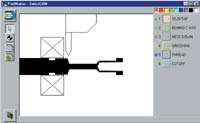

6. Visual Prove-Out: The Windows operating system gives today's CAM systems the ideal platform for verifying the manufacturing process every step along the way. As a result, when programming a part on a Windows-based CAM system, the programmer can see exactly how the part will be machined before committing resources.

Some Considerations

The decision about programming methodology is one of the most important ones a shop can make in the era of CNC. A production-machining environment offers its own host of special considerations in this regard. The approach to programming often even determines which machine tools a shop purchases.

For example, programming may differ drastically from one machine tool to another. Some machine tool builders provide their customers with a built-in or dedicated programming system only for use with a particular brand of machine tool. This programming approach can be very productive for a particular machine tool, but it does not help much if a shop has an assortment of different machine tools acquired over the years. A CAM system should be able to provide a uniform programming approach, meaning it should allow a shop to program a number of different machines in the same intuitive manner.

This is not to say that one size fits all in the world of CAM. Just as different shops have their specialties and niches, so too do different CAM systems. The same system used in one area of the shop to program free-form three dimensional surfaces or even molds probably has not been designed to take into consideration the unique requirements of your production machining lathes, turn-mill centers or Swiss-type lathes.

Closely related to the issue of which CAM system is right for a shop is that of post processors. A post processor, or "post" as they are often referred to, can most simply be defined as a utility that translates the data entered into a CAM system and the calculations performed in it into NC code for a particular machine tool. Different CAM systems take different approaches to post processors. Some CAM developers rely on outside companies to either develop posts for them or simply license technology to develop post processors to interface with their systems.

More popular among today's CAM systems is to use a utility developed by the same people who developed the CAM system to create post processors for new machines as well as augment post processors to suit the programming style of different users. Such systems will also typically allow end users to modify their own post processors in order to tailor the output of a given system to their own liking or even create new post processors themselves to support machines that their CAM system may not explicitly support. This process is referred to as configuring a post processor.

It is important not to confuse a CAM system for a post processor or vice versa. The CAM system is the front end for accepting data from the user about the part being programmed. The job of the post processor is to work in the background to convert this data into NC code. CAM systems not designed for your application simply do not have the data to pass to the post processor to generate the right NC code. As a result, getting the right code may only be achievable with a significant amount of manual editing, which is exactly what you are trying to avoid by purchasing a CAM system.

When it comes to Swiss-type lathes and multi-axis turn-mill centers, the importance of a flexible and reliable post processor is vital. These machine tools often require two and sometimes three programs to be generated for a single part in order to simultaneously control the motions of the machines' multiple axes. These programs are linked to each other through what are known as ‘Wait' or ‘Sync' codes, special NC codes that tell various machine actions when to move together. Inserting these sync codes has proven to be a stumbling block for many CAM systems.

The moral of the story is a simple one: To stay competitive in today's manufacturing environment you have to invest in high productivity CNC equipment. You want to protect this investment by making sure this equipment can operate productively. A good way to do so is to make sure your CNC programming can keep pace with your customers' changing production demands.

RELATED CONTENT

-

Program a Robot with your Machine’s CNC

A new function in popular controls enables shops to program machine-tending robots using familiar CNC G codes.

-

Let’s Talk About Less Machining Chatter

For some turning work, unwanted harmonics can cause chatter and poor surface finishes. A new CNC software capability can automatically compensate for this.

-

Adding 5-Axis Capability to a 3-Axis CNC Mill

This attachment provides shops using thee-axis machining centers the option of on-demand four- and five-axis machining.