Get an Inside Peek at 3D Printed Tooling

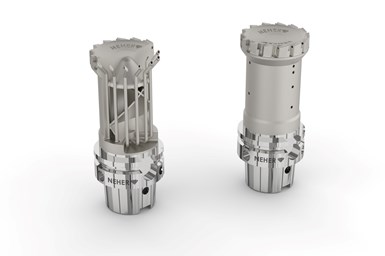

Booth features 3D-printed milling cutter, both a complete tool and a partial tool, to show internal cooling channels and other complex features.

#additive

Compared to traditional manufacturing methods, the company says additive manufacturing is more reliable in achieving designs with complex details and enhanced chip control than subtractive machining.

Photo Credit: Star SU

Star SU/Star Cutter Co. is showcasing the benefits of its 3D printed tools by displaying a partially completed finishing milling cutter that enables visitors to see the internal cooling channels and other complex features that can be achieved using additive manufacturing. Its booth 237013 also features the same 3D printed milling cutter in its completed state, enabling visitors to handle the cutter and experience the lightweight nature of the tool.

Compared to traditional manufacturing methods, the company says additive manufacturing is more reliable in achieving designs with complex details and enhanced chip control than subtractive machining. This ability enables optimization of the coolant hole sizes and cooling channel locations, making it well-suited for the MQL (minimum quantity lubrication) trend while improving tool life by 30% or more. With 3D printed tools there is also about a 30% reduction in tool weight, yet they have the equivalent torsional stiffness of a steel ground body tool, Star SU/Star Cutter Co. says.

Reducing tooling weight is especially important when working with large, heavy tools that take a toll on the machine spindle, according to the company. Lightweight tools can add stability to the process and help to reduce preventative maintenance. These improvements can be especially significant when producing aerospace and automotive components, including electric vehicle parts, where existing spindle interfaces are not always ideal for some of the size/weight of tools.

RELATED CONTENT

-

Cutting Tool Coating Production

This article looks at the coating methods available for carbide cutting tools.

-

Tools and Technologies for Deep Hole Drilling

Understanding the challenges of deep hole drilling and knowing how to select and apply the appropriate tools will help a shop profit from this operation.

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.