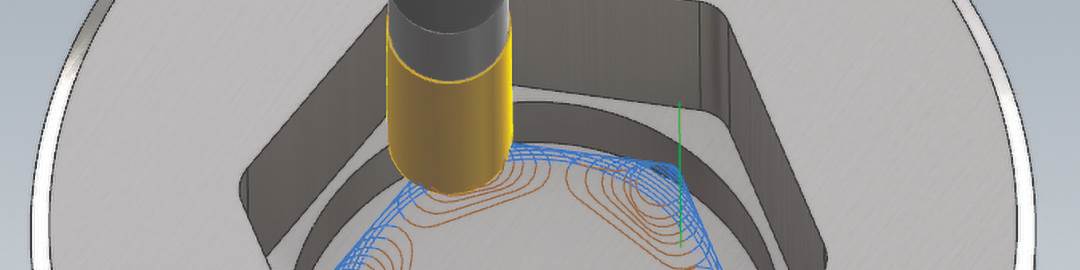

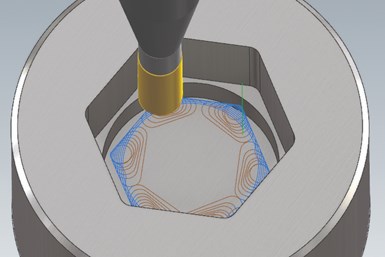

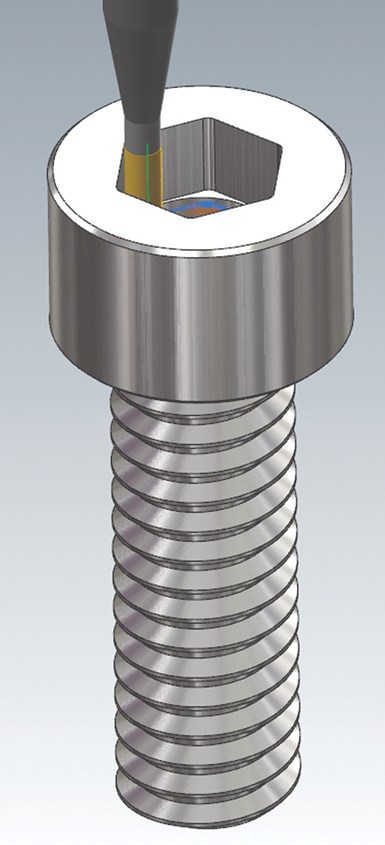

When a machine shop was looking for a faster process than its previous broaching method, Emuge-Franken Top-Cut VAR solid carbide end mill combined with Mastercam’s 2D Dynamic Motion trochoidal toolpath strategy produced an optimal tool path in this 718 Inconel bolt. (Photo credit: Emuge-Franken)

When leading machining technology companies combine efforts to improve processes or create entirely new strategies to produce parts, manufacturing customers can benefit by applying more productive machining solutions. One example is cutting tool and CAD/CAM companies working together to co-create better tools and tool paths that reduce cycle times, improve part surface finish and increase tool life.

For example, cutting tool manufacturer Emuge-Franken works closely with CAD/CAM software partners to optimize applications. Building on the depth of its milling tool technology, the company recently optimized end milling operations to take advantage of Dynamic Motion strategies available in Mastercam from CNC Software.

Featured Content

Many major metal cutting industries are increasingly moving to high-performance end mill designs with higher flute counts, which is associated with the significant advancements in CAD/CAM technology that incorporates Dynamic Motion strategies.

Dynamic Motion is a trochoidal toolpath strategy for both roughing and finishing operations that uses smaller radial step-overs with higher axial depths-of-cut. To optimize this approach, end mills must be specially engineered to maximize the many benefits that can be realized.

The first step in creating this bolt head profile via trochoidal milling is hole pre-drilling. (Photo credit: Emuge-Franken)

To meet the end mill requirements, Emuge-Franken greatly expanded its U.S.-made carbide end mill program with increased flute counts to include five-, six- and seven-flute configurations in various diameter and length combinations. When a Dynamic Motion strategy is used in conjunction with an end mill and toolholder that is optimized for this type of cutting process, shops can realize significant cost savings when compared to older strategies.

In an application that used a 5/8-inch Extra-Long Top-Cut VAR end mill clamped in an FPC collet tool holder, a full slot in Monel 500 high-nickel-based material was milled using a trochoidal cutting strategy that produced a cost saving of approximately $8,500, almost 40% less than the previous setup.

Another notable accomplishment due to a CAD/CAM partnership is when Emuge-Franken teamed up with Open Mind Technologies to develop circle segment end mills (conical barrel cutters) which work in tandem with a HyperMill five-axis tool path, reducing metal removal step down passes, improving surface finishes and reducing cycle times up to 90%.

Using the appropriate toolholder is also critical for machining application success, so Emuge-Franken works closely with toolholder partners to meet customers’ challenging requirements. By conveying customer feedback about certain applications, including five-axis machining of smaller parts, to toolholder partner Albrecht Precision Chucks, the result became a versatile new chuck design.

FPC Precision Micro Chucks (bottom right) are very productive for small parts manufacture where a larger holder might run into the part — shown here as part of the FPC line of Precision Chucks.

Photo Credit: Emuge-Franken

Although Emuge-Franken FPC chucks are a proven solution for many applications, in certain instances, the holder’s nose diameter is too large or needs extra reach to avoid machine crashes. After close collaboration to establish a new design, a new FPC chuck solution was developed offering a compact, slim design with a tapered shape, enabling improved access to a workpiece, especially in confined areas and at challenging angles. In a turn-mill application, an FPC Slim Line toolholder was used to avoid crashing into the lathe chuck. This enabled the tool to get closer to the chuck jaws and remove more material in the same roughing operation. By applying new tool geometry and milling strategy together with the FPC Slim Line holder, cycle time was reduced by approximately 25%.

In addition, the FPC Slim Line became the impetus for a microchuck version to accommodate smaller tools used for milling fine details and finishing work. The microchucks are productive for small parts manufacturing in which a larger holder might collide with the part. For example, the FPC microholder was needed for a very small impeller application. To mill the hub surface, the microholder had to fit between the blades where there was only 15-mm available spacing. The small diameter and long neck of the holder enabled the tool to reach the hub surface

About the Author

Evan Duncanson is a milling application specialist for Emuge-Franken USA.

RELATED CONTENT

-

VIDEOS: Tips for Screw Making on Swiss-Type Machines

Here’s a three-part video series focused on Swiss screw making to help explain the benefits of thread whirling, back turning and broaching while taking into consideration CAM programming, tooling and machine specifications.

-

Swiss Shop Chooses CAM Over Hand Programming

This shop’s manual (by hand) CNC programming was slowing it down until it discovered a CAM software for Swiss-type lathes.

-

Precision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.