Mazak Event Targets Aerospace, Medical

While in the area for EASTEC last month, I attended Mazak Corporation’s “Discover More with Mazak” event at its Northeast Technology Center in Windsor Locks, Conn. The 3-day event highlighted a lineup of the company’s manufacturing systems.

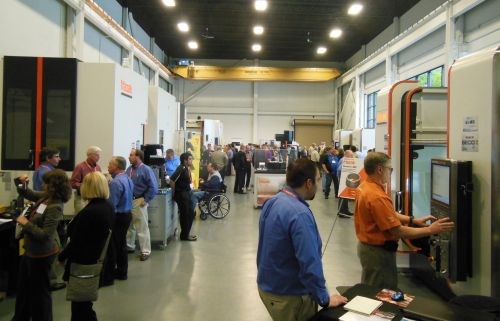

While in the area for EASTEC last month, I attended Mazak Corporation’s “Discover More with Mazak” event at its Northeast Technology Center in Windsor Locks, Conn. The 3-day event highlighted a lineup of the company’s manufacturing systems designed to meet the ever expanding production needs of the area’s aerospace, medical and other manufacturing sectors.

The machine tool demonstrations included three new machines—the Variaxis i-700, the Variaxis i-800, and the Vertical Center Universal 400. Other machines at the event included the Integrex i-630V (for heavy-duty 5-axis cutting), the Integrex i-200S (with twin turning spindles and a milling spindle), and the Megaturn Nexus 900M (combining turning and secondary machining operations for large cast iron and steel workpieces). Other demonstrations addressed real-world applications, including aerospace hard-metal machining on a horizontal Nexus 6800 HM (hard metal package) and medical implant machining on a vertical Nexus Compact.

The event also included several technology presentations and expert guests that provided attendees with valuable manufacturing insight. On Wednesday, May 15, keynote speaker Richard Aboulafia, of the Teal Group (a company that supplies independent aerospace and defense industry market analysis), shared his knowledge of the aviation and aerospace industries and spoke about the commercial airline industry.

RELATED CONTENT

-

Hard Turning as an Alternative to Grinding

Hard turning can be a cost effective alternative for shops looking to streamline part processing.

-

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.

-

New Line of Swiss-Types for Job Shops Eyeing High-Production Work

Mazak now offers the Syncrex line of Swiss-type CNC lathes — its first — targeting machine shops getting into higher volume production of complex parts.