Turn-Mills: Being About the B-Axis

With the addition of powerful B-axis milling spindles and automatic toolchangers, turn-mills combine the best of milling and turning worlds.

For many machine shop people, the B-axis turn-mill platform is the first that comes to mind when they think of “multitasking machines” that often can complete parts in one setup. But, while that equipment most closely resembles a lathe, are they lathes or mills? The answer is: both. It’s this five-axis platform in particular whereby the line between mill and lathe is most blurred.

When referencing the “B-axis,” we’re talking about the rotation of the turn-mill’s milling head that enables the head to perform work from various angles on the side or end of a part held in a main or subspindle. This is shown in the photo above for an application that, ironically, calls for no turning work (a rotor for an automotive supercharger). In fact, five-axis capability thanks to the B-axis opens up the opportunity to process fully prismatic parts from barstock, billets, castings or forgings as well as machine contoured parts like, the rotor shown above, or even turbine blades. Plus, some turn-mill models can perform gear hobbing and skiving or be fitted with additive-manufacturing laser cladding units for repair work of large parts or the addition of small features to large parts.

The video below shows common operations a turn-mill can perform. In this case, an Integrex i-100ST machine with subspindle from Mazak demonstrates pinch turning as well as other simultaneous turning and milling operations on both the main and subspindle.

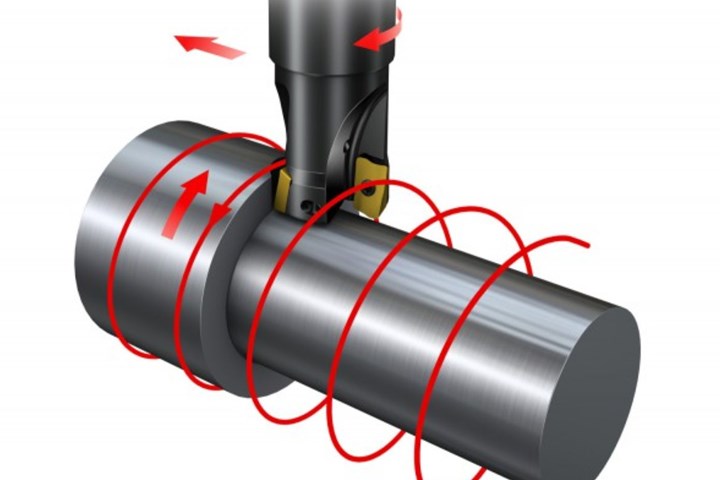

These machines can also use the B-axis milling spindle to perform “turning milling,” in which instead of feeding a static, single-point turning tool down the Z-axis, a spinning milling tool is moved down the part to “turn” the diameter.

Unlike single-point turning, he “turning milling” advances a spinning milling tool down a rotating part. Higher material removal rates are possible. (Image courtesy of Sandvik Coromant.)

According to Sandvik Coromant, the method allows for high metal removal with good chip control. It can also produce eccentric forms such as oblong cam shapes or contoured turbine blades by feeding the cutter along more than 2 axes while simultaneously rotating the part.

A static turning tool installed in a B-axis milling spindle enables a turn-mill to perform contoured turning work, too. Okuma offers a B-axis turning function for face turning operations on its Multus series machines. That, plus skiving capability for ID and OD splines as well as on-machine touch probing for measuring part features such as diameter, roundness and taper angle is shown in the video below.

Turn-mills also make sense to create big, shaft-like components that require milled features as shown in the following video of a Weingärtner MPMC turn-mill machining a large crankshaft.

Some B-axis turn-mill platforms resemble mills more so than lathes, although they can perform turning work. The Bumotec s181 in the video below is an example. Instead of having a subspindle, it features part support and clamping to enable subsequent backworking with live tooling to complete parts such as surgical laminal hooks.