Zero-Point Clamping System Offers Increased Flexibility

Appears in Print as: 'Combo Clamping System Offers Increased Flexibility'

PMTS 2023: The Combi series features an integrated 52- and 96-mm zero-point grid which enables users to clamp the complete range of applicable Lang vises in the same zero-point unit.

#PMTS

Edited by Angela Osborne

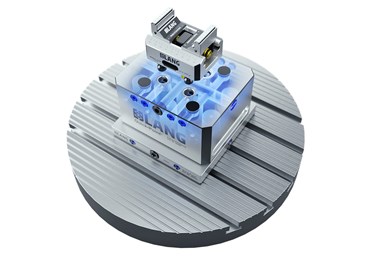

The Combi series offers two different grid dimensions in one zero-point unit. Photo Credit: Lang Technovation

Lang Technovation’s 52- and 96-mm Quick-Point clamping systems offer a 2-in-1 solution for greater flexibility, high precision and shorter setup times. The Quick-Point is said to combine all the features that make a zero-point clamping system special. A new series within the Quick-Point zero-point clamping system takes this to the next level and enables users even greater flexibility in their manufacturing needs.

The Combi series offers two different grid dimensions in one zero-point unit with selected plate types from Lang Technovation’s zero-point clamping system now available as a combo version. The Combi series with integrated 52- and 96-mm zero-point grid enables users to clamp the complete range of applicable Lang vises in the same zero-point unit.

The flexibility of the mechanical zero-point clamping system is further increased in terms of application versatility, while at the same time reducing the time required for changeovers. In smaller machine tools with little travel in the Z-direction, the elimination of an additional adapter plate can also be helpful.

The combo plates are available in square and round designs, as well as in a version with a clamping edge. Lang Technovation also offers its combo solution as a 5-axis riser and as a twin base for 3-axis machines and rotaries.

RELATED CONTENT

-

Manufacturing Automation Beyond Robots at PMTS

A variety of automated machining and manufacturing processes — including, but not limited to, robotics — that can enable shops to become more efficient were on display at the recent Precision Machining Technology Show.

-

Two Bits of Good News to Start 2021

The Precision Machining Technology Show has moved from April to August and Production Machining turns 20. These are both good things.

-

Thoughts about PMTS, Machining Automation

Turning technology, as was displayed at the Precision Machining Technology Show, is more advanced than ever and machine shops should continue to identify processes of all types that can be automated.