If you attended this year’s PMTS, what caught your eye? Was it some element of automation? How was your experience? Email me at dkorn@productionmachining.com to let me know.

In the precision machining world, the term “automation” typically evokes images of robots tending machine tools. Robotic automation certainly has had a big impact on shops facing a shortage of skilled workers as well as those looking to perform long stretches of unattended machining (in some cases, lights-out, overnight). For example, the article on page 30 describes one shop’s story integrating its own robot that eventually was paired with a pallet-changing VMC for a high-volume job drilling stainless steel tubes. Interestingly enough, the robotic automation came before there was work for it to support. In addition, the article on page 26 explains the advantages of having a robot integrated inside a CNC turning center. This design not only offers advantages (such as reduced floor space) but also improved chip evacuation using the robot to direct a coolant stream at the point of the cut as well as using the robot to help support long workpieces during turning to minimize chatter.

Was automation on your mind at PMTS?

However, there are myriad other forms of automation that shops can leverage to their advantage even beyond bar feeders, the most common means to automate a CNC turning center. Many examples were evident at the recent Precision Machining Technology Show (PMTS) held last August in Cleveland, Ohio. Here, we describe five: automated data collection from all CNC machines in one exhibitor’s booth, vacuum parts collection, 3D part measurement, tool presetting and parts cleaning process monitoring.

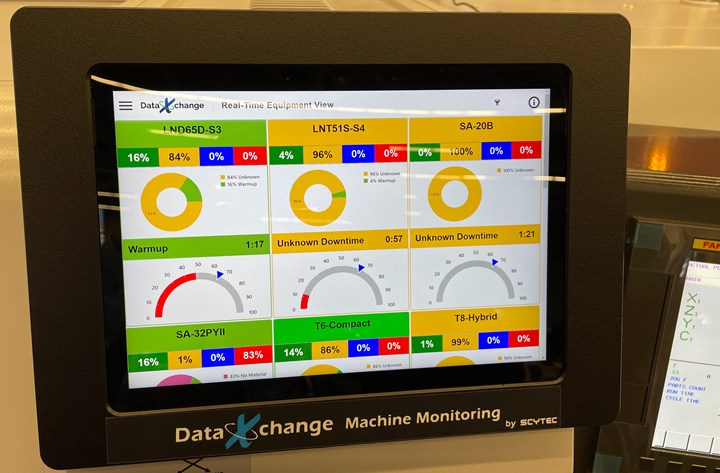

All six CNC machines in Absolute Machine Tool’s PMTS booth, including Lico, Nexturn and Quicktech brands, were connected via DataXchange machine monitoring technology from Scytec. Monitors and displays throughout the booth showed real-time machine status as well as the configurable dashboards and data interfaces possible within the software. The idea was to demonstrate how an entire machine shop could be connected in a similar fashion. Scytec says those who are new to machine monitoring systems typically ask about what’s involved getting machines connected and ensuring security. Those that have some experience with machine monitoring systems are more likely to ask about what to do with the data. The company suggests that shops start by connecting and monitoring just a few machines and tracking a simple metric such as spindle on time. After that, a shop can then “grow with the data.” Scytec says that, because it offers month-to-month, one-year and two-year subscriptions, it’s easy to start small without a significant upfront investment.

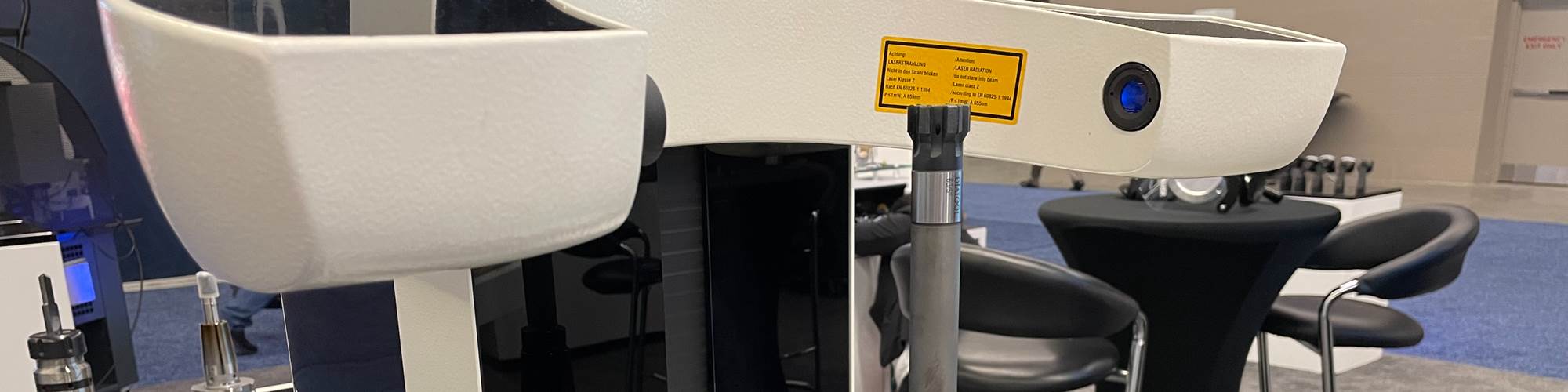

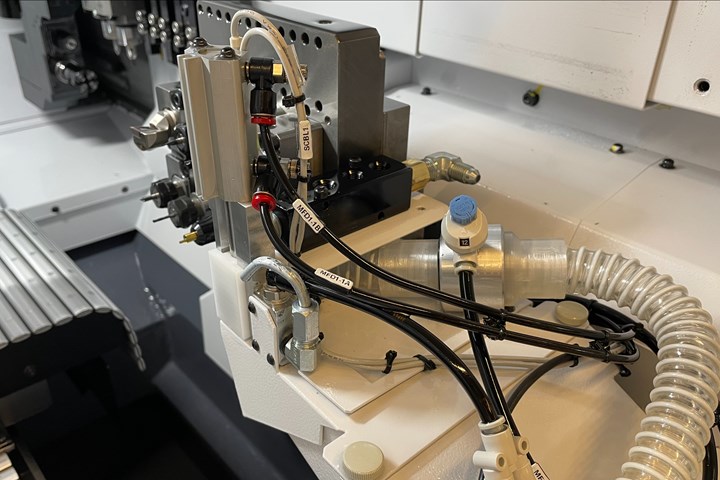

Automated removal and handling of parts after machining can be challenging, especially for very small parts that might get lost in the chip conveyor or traditional parts chute, and/or can’t impact each other causing their surfaces to be marred. For Swiss-type lathes such as its L20 XII B-axis machine with automatic tool changer, Marubeni Citizen-Cincom offers an optional vacuum ejection system to pull and collect small parts once machining is completed. The system consists of a 3D-printed device that creates the vacuum and pulls completed parts ejected by the spindle through a tube and into a 3D-printed collection device. The collection unit’s funnel shape slows parts so as not to damage them as they gently fall to the bottom of the unit. The system uses either a timer or sensor to determine when a part has entered the collection unit to then shut off the vacuum device.

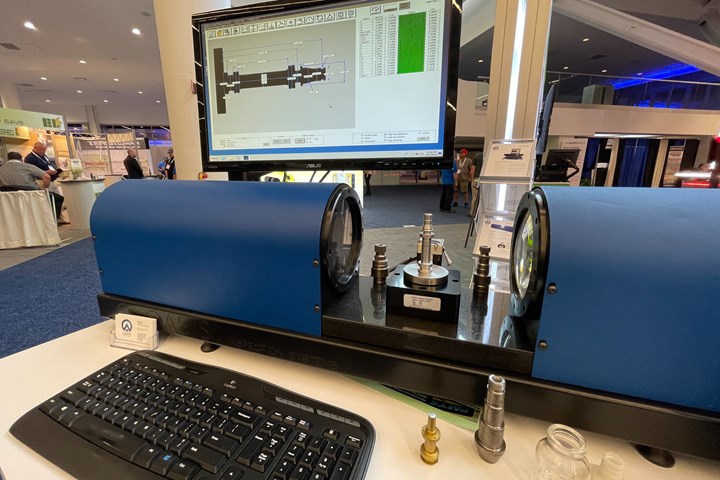

Part measurement can become a bottleneck, especially for high-volume production shops. Devices such as non-contact optical systems from Oasis Inspection Systems automatically measure multiple profile dimensions on small parts simultaneously and in real time with all measurements done in less than a second. In fact, the addition of a motorized rotary stage turns this 2D inspection process into a 3D process. Inspectors can ensure that their parts are within specification limits all the way around without manually turning the part. In addition, rotating the part adds the ability to check additional features such as roundness and concentricity. With the included software update, all of this additional data is recorded with the built-in Oasis inspection report or can be automatically imported into any statistical process control (SPC) program. In continuous mode, the part continuously rotates on the stage at a user-defined speed to enable the inspector to view the measurements and status display panel as the part turns. In fixed-duration mode, the inspector defines how many rotations the stage will make and how many times to measure the part while rotating.

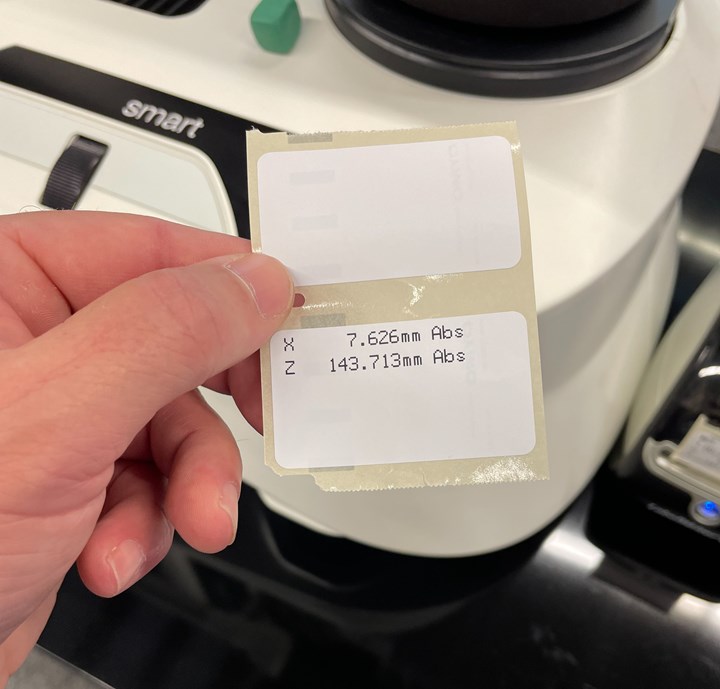

Manually measuring tool offsets is a time-consuming process. Haimer says it commonly takes 300 seconds per tool to measure a tool in a machine. Plus, when using a machine tool as the “presetter,” an expensive piece of equipment is not doing what it is supposed to be doing — making chips. The company says this time can be reduced by 70% using an offline tool presetter to automatically measure attributes such as tool height, diameter and runout. Even entry-level presetters can support as many as 10 machine tools. In fact, Haimer has 140 machine tools in its 200,000-square-foot German manufacturing facility in Igenhausen, near Augsburg. In the main tool crib is a Vio Linear full CNC tool presetter. However, when a tool breaks on a machine far from the tool crib, the operator can choose to use one of 10 Uno Smart tool presetters installed throughout the facility to change one tool rather than walking to the tool crib. For live-tool lathes, presetting complements the company’s new line of shrink-fit collets that enable faster changeovers for those types of machines than conventional collets, too.

Part cleanliness demands continue to become more stringent and there are a variety of cleaning methods for shops to consider. Ecoclean says its EcoCwave aqueous parts cleaner with a spray-flood cleaning system and vacuum-tight work chamber offers advantages in that it can be configured to suit a variety of applications. In addition, the company offers automated process monitoring with Ecoclean Connect cloud-based software designed to optimize the acquisition of parts cleaning data while displaying all system and process data on a computer or tablet. Defined data generated by the cleaning system’s control unit is transmitted to the cloud in encrypted form via a secure connection. The company says data is stored, evaluated, analyzed and intelligently linked using the latest Internet of Things (IoT) technologies and infrastructures. Process visualization includes preselections and step sequence display; operating data history; overview of key performance indicators such as utilization and effectiveness; message archive; and statistics. Documentation includes an overview of all cleaning processes performed; individual cleaning process reports (including process parameters); management of cleaning programs with version history and reporting; a library for all key documents related to the system; and a timeline for important events.

RELATED CONTENT

-

Learn about some of the new CNC turning centers and Swiss-Type lathes to be displayed at PMTS 2021.

-

Learn about some of the new automation and measurement solutions for precision machining that will be on display at PMTS 2021.

-

Learn about some of the new multipurpose machining centers that will be on display at PMTS 2021.