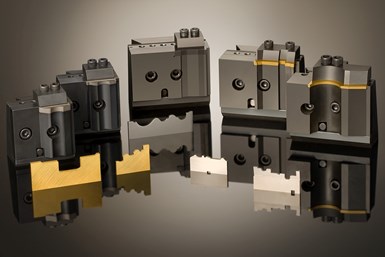

Double-Datum Tooling Carbide Tooling With Interchangeable Components

Appears in Print as: 'Carbide Inserted Toolholders With Interchangeable Components'

PMTS 2023: These carbide inserted toolholders are said to reduce downtime with fewer tool changes plus faster tool changeover.

#PMTS

Edited by Lori Beckman

Double-Datum Tooling from Posa-Cut are carbide inserted toolholders with interchangeable components making them well suited for short and long runs. They are said to reduce downtime with fewer tool changes plus faster tool changeover. The design accommodates both radial and axial differences between parts.

A replaceable insert enables users to optimize geometries, grades and coatings, all designed for specific applications. Machine downtime for resharpening is eliminated.

The design works especially well with families of similar parts that are run on the same machine(s). The changeover time between parts can be significantly reduced because the holder base does not need to be removed from the machine. The front plate on the holder base is switched out with one designed for the next part.

The company’s full-service engineering department can design the tooling system for use on many types of machines. The holder base can be made in dovetail, straight shank or circular designs.

RELATED CONTENT

-

When Thread Milling Makes Sense

Threading a workpiece is a fundamental metalworking process that every manufacturing engineer takes for granted.

-

The Many Sides of Workholding

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

.png;maxWidth=970;quality=90)