Heidenhain Touch Probe for Soft, Delicate Workpieces

Appears in Print as: 'Touch Probe for Soft, Delicate Workpieces'

Heidenhain’s TS 750 touch probe operates with high-precision pressure sensors with force analysis for generating the trigger pulse.

Edited by Angela Osborne

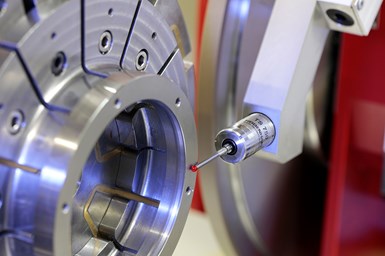

TS 750 high-precision touch probe features a low probing force for working with soft or delicate workpieces. Photo Credit: Heidenhain

Heidenhain’s TS 750 touch probe is designed for high-precision, in-process workpiece measurement in grinding machines and lathes. The company says the probe is extremely durable and offers the ability to state the reproducibility of its jobs at increased probing speeds better than most competitors. It is said the touch probe’s low probing force is a benefit when working with soft or delicate workpieces.

The touch probe operates with high-precision pressure sensors with force analysis for generating the trigger pulse. The forces that arise during probing are processed electronically. This method is said to deliver homogeneous, 360-degree probing accuracy. It offers high probing speed of up to 1 m/min and does not require a minimum speed.

Also, due to its low probing forces of approximately 1.5 N (axial) and 0.2 N (radial), the TS 750 can attain high probing accuracy (±1 micron) and repeatability with almost no effect on the measured object, the company says. Only on further deflection do the forces of the springs take effect until the machine stops.

The company says the probe continues to deliver reliable measurements after prolonged use — even after 5 million probing cycles. The TS 750 touch probe is still highly accurate with a probing repeatability of down to 2 σ ≤ 0.25 micron at its high probing speed.

RELATED CONTENT

-

Reducing Downtime With Tool Presetting

It’s an ongoing challenge. To remain competitive, shops must find new and more efficient ways to increase production. Often they look to new, faster and more precise machine tools as the answer. Sometimes experimentation with a variety of different tooling

-

Measure 3D Parts Without Losing Time

This high-speed metrology and inspection system is said to process complex geometries faster than traditional inspection methods.

-

Setup Options for Swiss Automatic Lathes

A hydraulic chuck and a counter-balanced centering tool, originally developed as in-house solutions, are now available to address the limited working space that is common in Swiss machining.